Self-sealing manhole cover plate dismounting tool for power station container equipment

A technology for manhole cover and container equipment, applied in the field of mechanical design, can solve the problem that the manhole cover cannot be accurately aligned with the sealing surface, the manhole cover collides with the sealing surface of the equipment, and the disassembly and assembly of the manhole cover is difficult. Large and other problems, to achieve the effect of improving stability and reliability, light weight and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

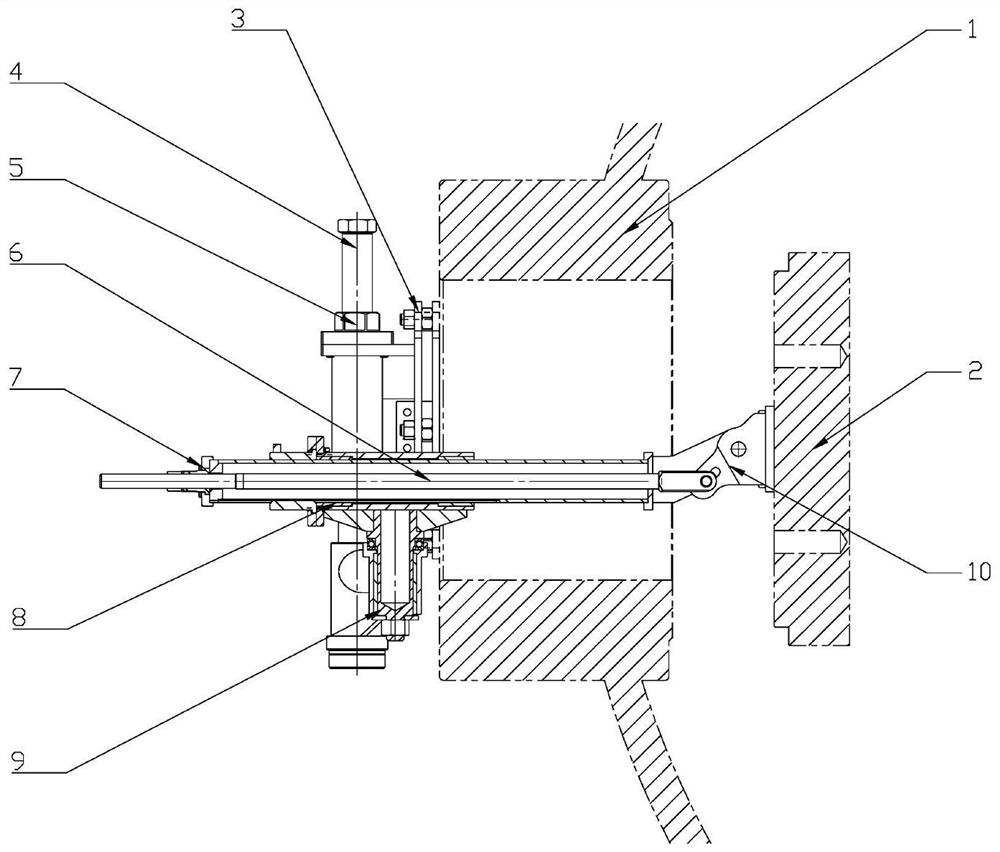

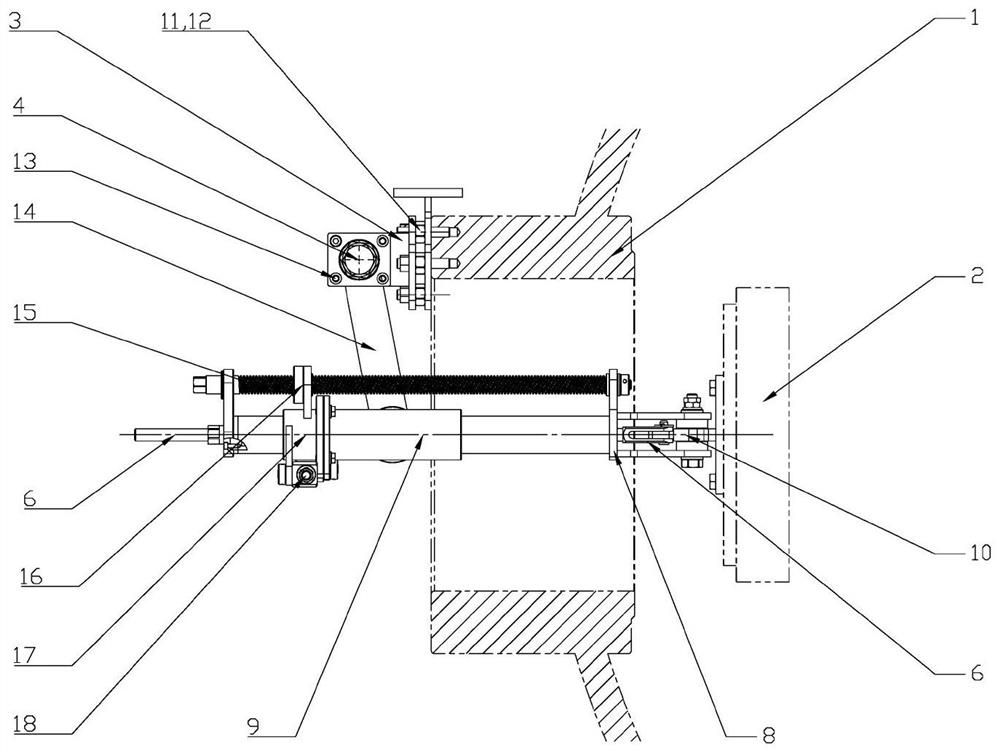

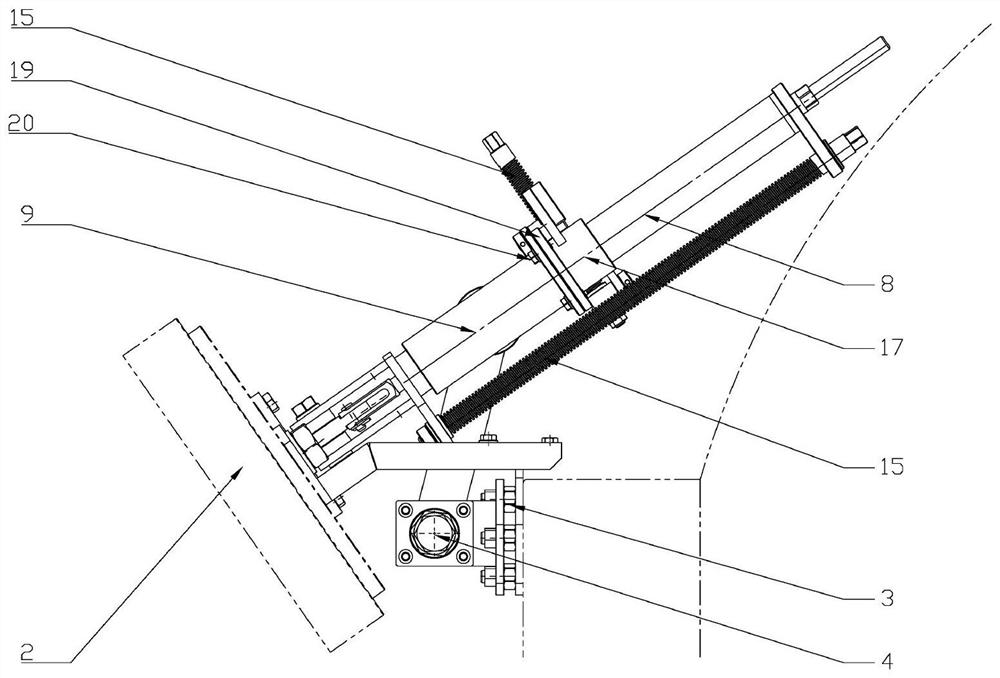

[0026] A tool for disassembling and installing self-sealing manhole cover plates for power plant container equipment provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] Such as Figure 1-5 As shown, the invention provides a self-sealing manhole cover removal tool for power station container equipment, which can realize the movement, rotation, flip and position adjustment of the manhole cover, including the manhole flange mounting seat 3, the lifting screw 4. Lifting screw nut 5, flip screw nut 6, flip screw nut 7, support tube 8, sliding support seat 9, manhole cover mounting seat 10,

[0028] The manhole flange mounting seat 3 is fixed on the high pressure heater manhole flange 1 through stud bolts 11 and nuts 12, the lifting screw 4 is installed in the sleeve of the manhole flange mounting seat 3, the lifting screw nut 5 and the lifting screw 4 pass through Threaded conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com