Mounting method of instrument board cross beam mounting plates and instrument board cross beam mounting plates

An installation method and instrument panel technology, applied in transportation and packaging, connection between superstructure subassemblies, superstructure subassemblies, etc., can solve problems such as poor position accuracy, improve position accuracy and reduce welding The effect of tolerance and relative position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Various embodiments of the invention will be described with reference to the accompanying drawings. In the drawings of the specification, elements having similar structures or functions will be denoted by the same element symbols. It can be understood that the drawings are only for the purpose of illustrating various embodiments of the present invention, and are not intended to describe the present invention exhaustively, nor limit the scope of the present invention.

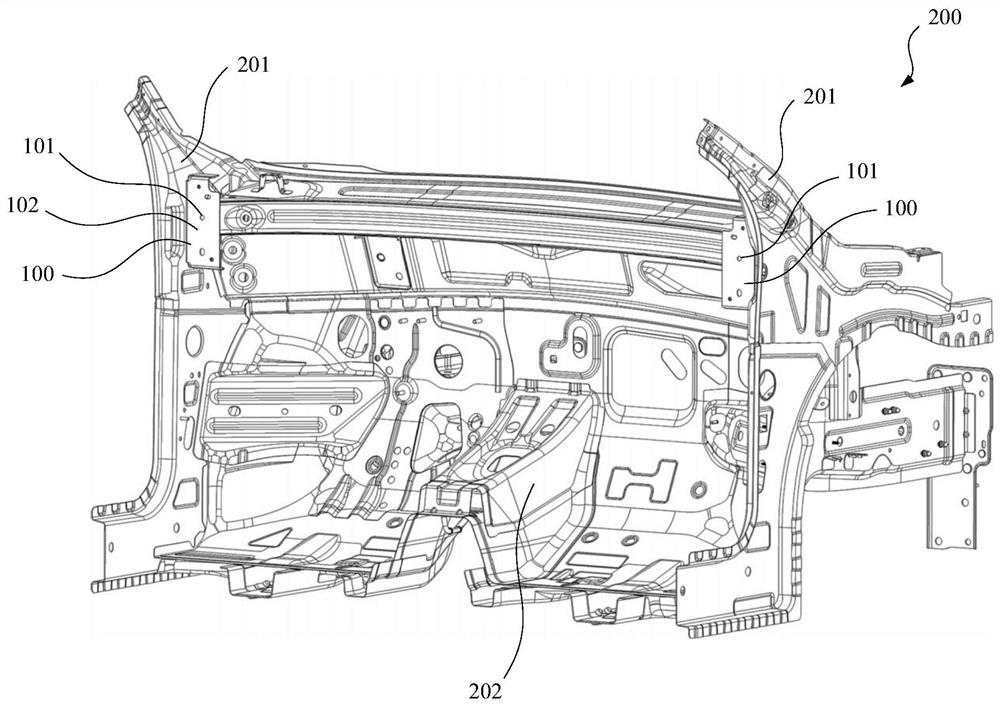

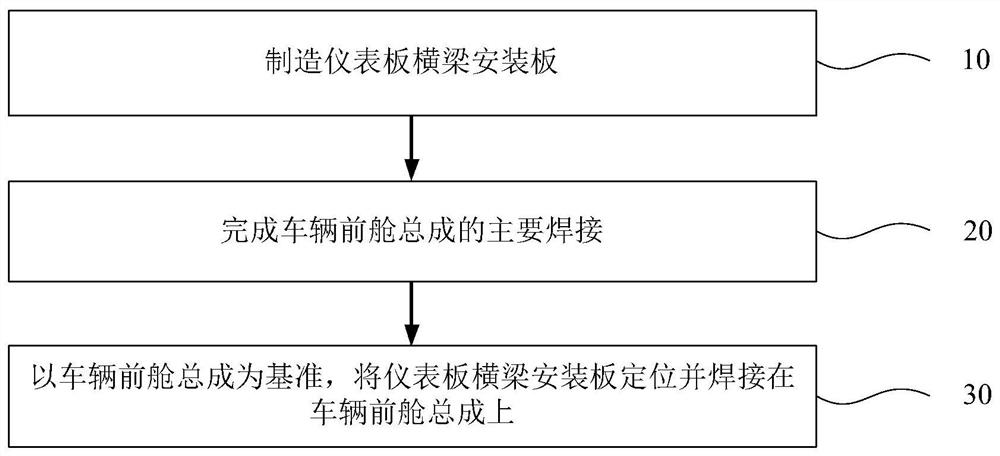

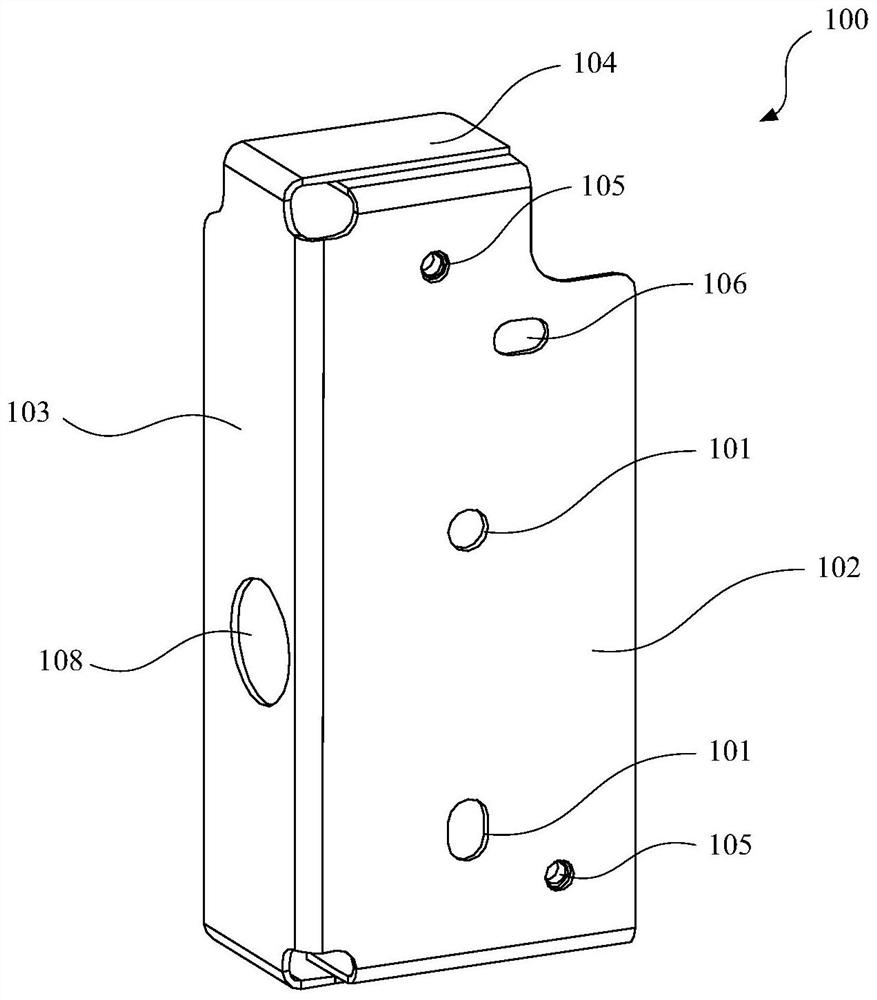

[0043] The present invention provides a method for installing an instrument panel beam installation plate 100 . Such as figure 1 As shown, it is used to weld the left and right instrument panel cross beam mounting plates 100 to the corresponding A-pillar upper inner panel 201 of the vehicle front compartment assembly 200 to form an instrument panel cross beam ( not shown in the figure) installed interface. Such as figure 2 As shown, the installation method includes the following steps:

[0044] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com