590MPa or above grade reinforced formability hot-dip galvanized dual-phase steel and preparation method thereof

A dual-phase steel and hot-dip galvanizing technology, which is applied to heat treatment equipment, furnace types, heat treatment furnaces, etc., can solve problems such as excess elongation, difficult forming, and large welding problems, so as to improve forming performance, meet forming requirements, and be good Effect of elongation and work hardening properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

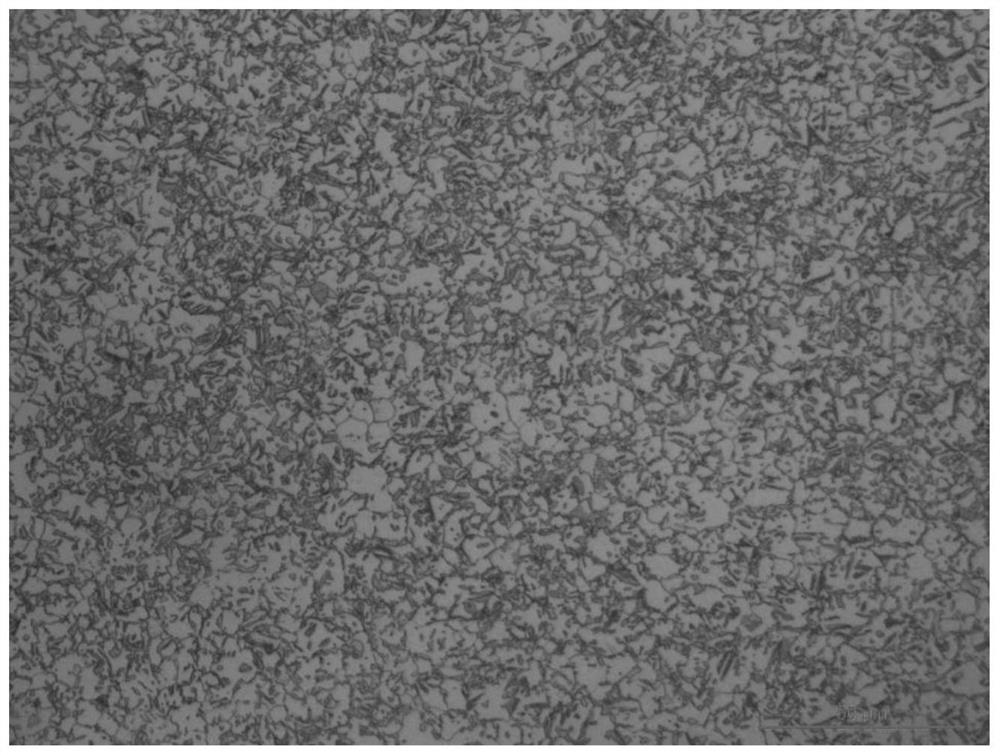

[0023] The invention solves the technical problem of how to improve the formability on the basis of meeting the strength requirement and not increasing the cost of the alloy by providing a hot-dip galvanized dual-phase steel with enhanced formability at a level above 590MPa.

[0024] The technical solution in the embodiment of the present invention is to solve the above-mentioned technical problems. The TRIP effect produced by austenite can improve the elongation of hot-dip galvanized dual-phase steel. The specific element ratio and its main functions are detailed in the following description.

[0025] C: 0.14%~0.16%, Si: 0.10%~0.15%, Mn: 1.6%~1.8%, P: ≤0.015%, S: ≤0.007%, Al: 0.6%~0.8%, Nb: 0.008%~0.015 %, N: ≤0.005%, the rest is Fe and unavoidable impurities.

[0026] The C element plays a role in stabilizing the austenite. Reasonable control of the proportion of the C content in the cooling process can obtain a certain amount of stable retained austenite and ensure the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com