Foam detection method of clothes treatment equipment, clothes treatment equipment and storage medium

A technology of clothing processing equipment and detection method, which is applied to the foam detection of clothing processing equipment, clothing processing equipment and storage medium fields, can solve the problem that foam cannot be accurately detected, and achieve the effect of ensuring safe and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

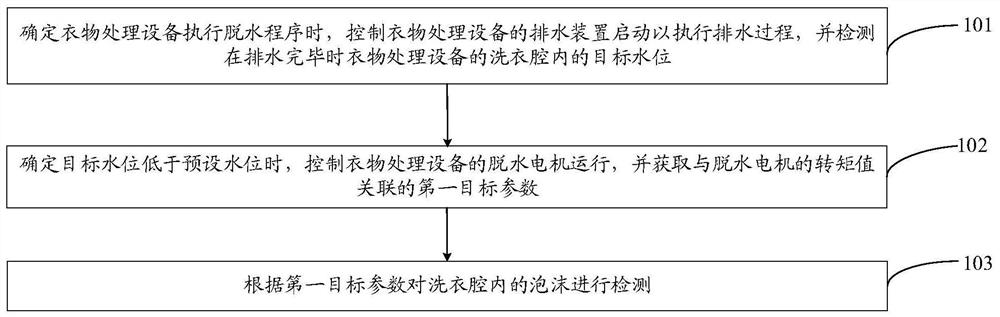

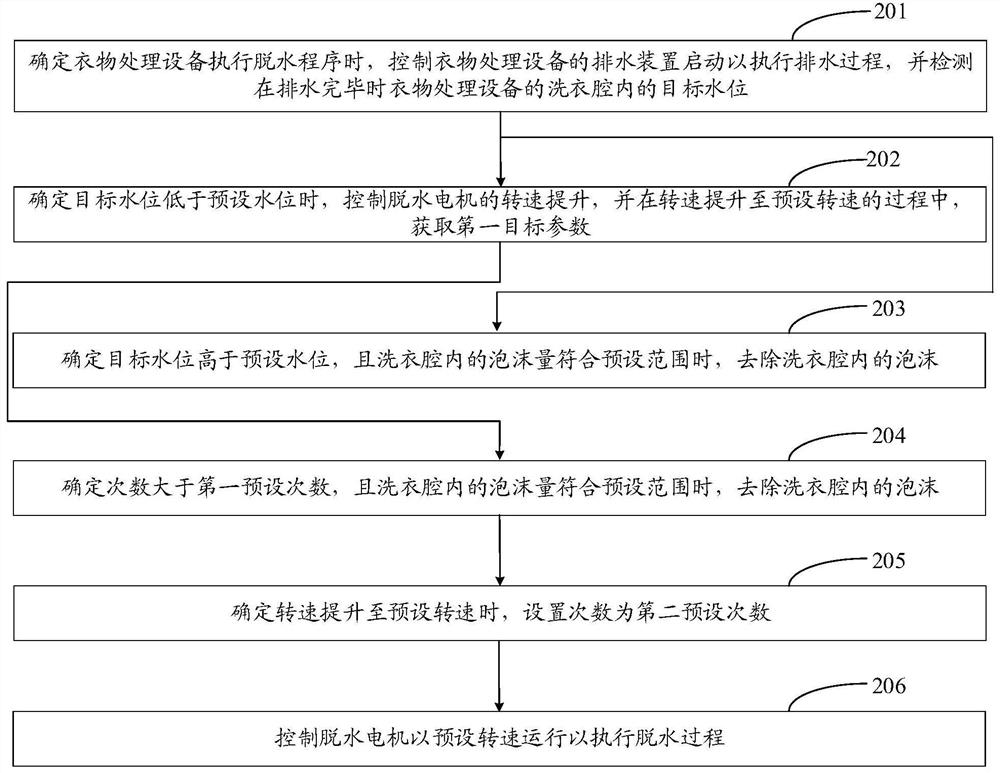

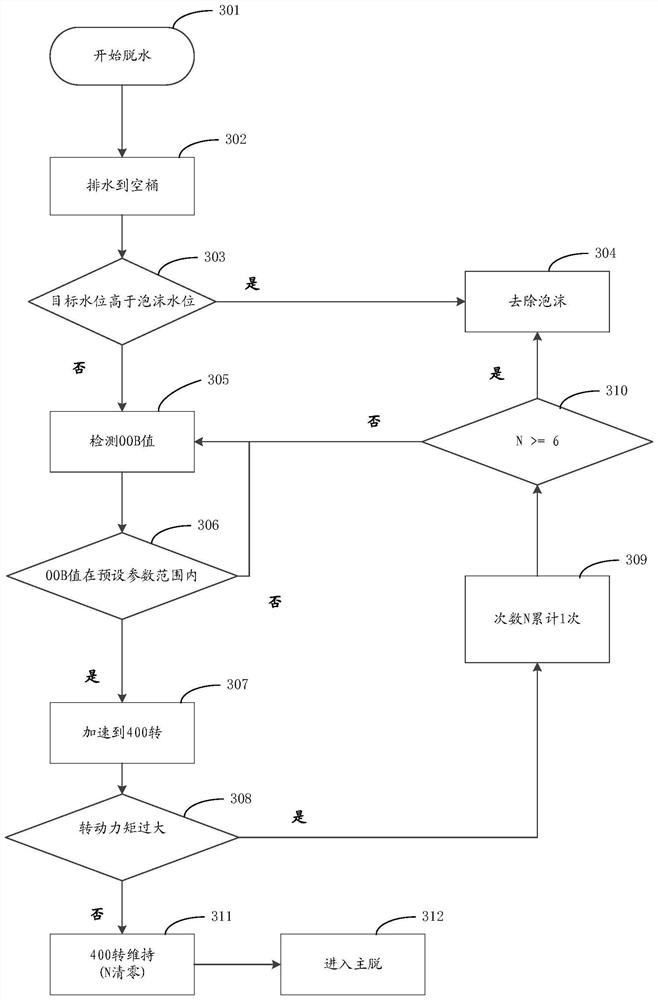

[0034] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0035] It should be understood that references to "an embodiment of the present application" or "the foregoing embodiment" throughout the specification mean that a specific feature, structure or characteristic related to the embodiment is included in at least one embodiment of the present application. Therefore, appearances of "in the embodiment of the present application" or "in the foregoing embodiment" throughout the specification do not necessarily refer to the same embodiment. Furthermore, the particular features, structures or characteristics may be combined in any suitable manner in one or more embodiments. In various embodiments of the present application, the serial numbers of the above-mentioned processes do not mean the order of execution, and the execution order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com