Road crack pouring device for municipal engineering

An engineering and road technology, applied in the field of road joint filling devices for municipal engineering, can solve the problems of insufficient stability of filling joints, inability to achieve rapid solidification of fillers, and inability to clean road gaps and debris, and achieve good cleaning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

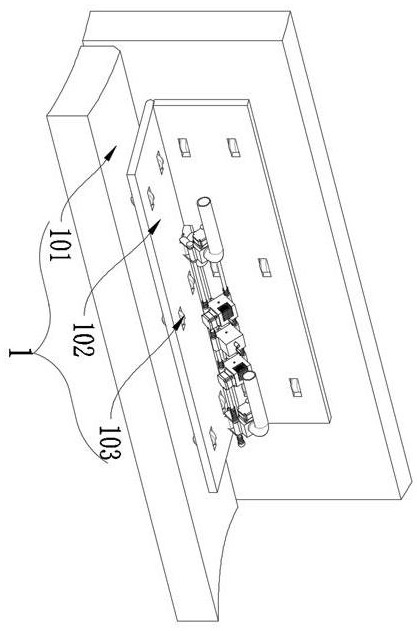

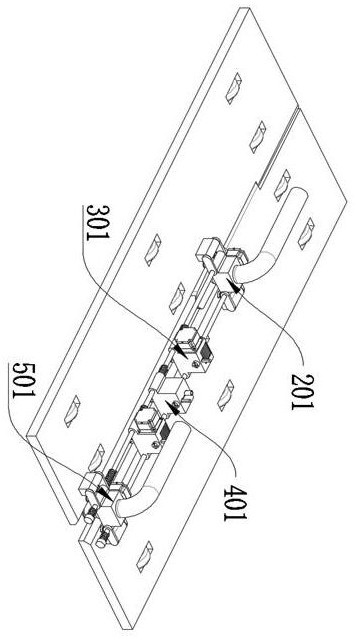

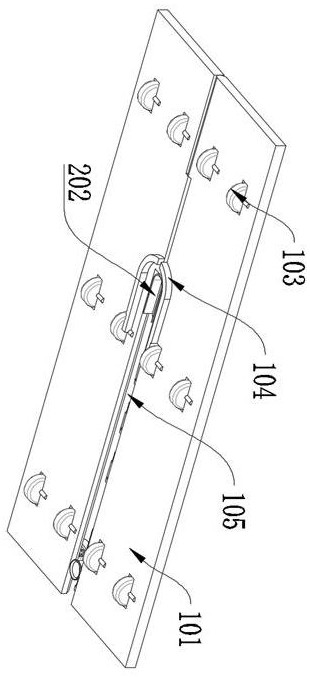

[0036] as attached figure 1 To attach Figure 9 Shown:

[0037]The invention provides a road joint filling device for municipal engineering, comprising an installation structure 1; a cleaning structure 2 is installed on the left end of the installation structure 1; an air blowing structure 3 is slidingly installed on the right end of the cleaning structure 2; an air blowing structure 3 is slidingly installed on the right side The smearing structure 4; the right end of the installation structure 1 is slidingly installed with an auxiliary structure 5; the clamping structure 6 is installed on the smearing structure 4 and the air blowing structure 3; The plate 102 is provided with two pieces, and the two mounting plates 102 are hingedly installed with each other. Each mounting plate 102 is equipped with six sets of pulleys 103, and the outer wall of each set of pulleys 103 is made of non-slip plastic material. Contact, set the mounting plate 102 into two groups hinged with each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com