Loading mechanism for full-section rock loading and loader-digger with loading mechanism

A loading mechanism, full-section technology, applied in mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc., can solve the loading that cannot cope with the full-section rock loading of the mine surface, and affects the ore excavation and loading. , large vibration and other problems, to ensure the loading effect, reduce vibration, and ensure the effect of angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

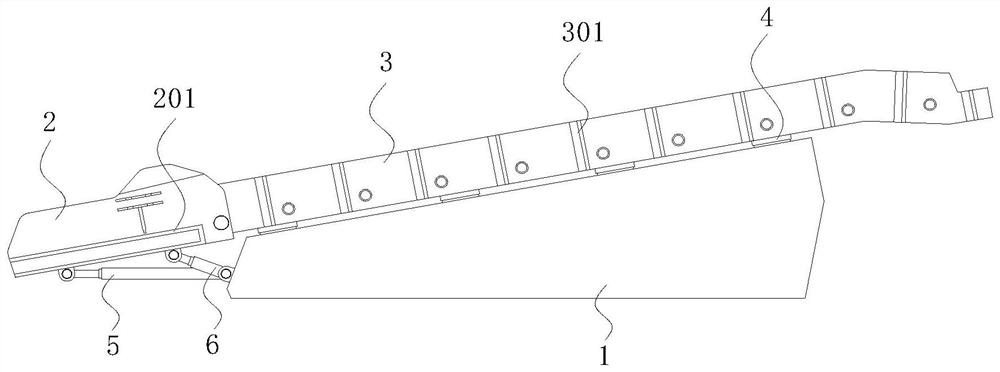

[0036] The core of the present invention is to provide a loading mechanism for full-section rock loading. The loading mechanism takes into account the loading of the full-section mine face and the transmission of ore and slag, which reduces the vibration when the ore is transported, protects the equipment, and improves the mine performance. Material loading and transport effects.

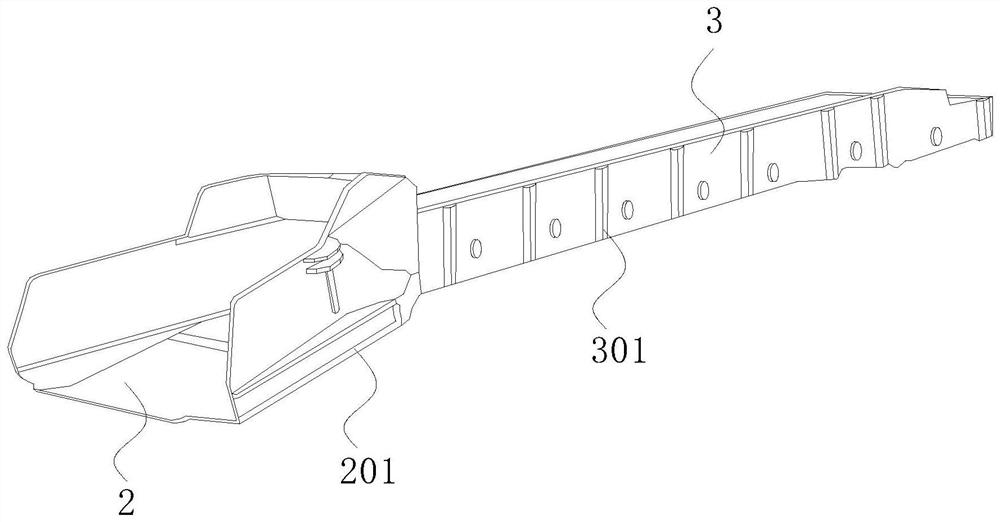

[0037] A loading mechanism for full-section rock loading, including a body 1, a rock loading bucket 2 arranged on the front side of the body 1 for loading rocks in the full section of a mine face, and a mineral material transmission tank 3 for transporting mineral materials and slag materials, The input end of the mineral material transmission tank 3 extends into the rock loading bucket 2 and is rotationally connected with the inner wall of the rock loading bucket 2 through two oppositely arranged adjusting shafts 9, and the inner cavity of the mineral material transmission tank 3 is provided with a ...

Embodiment 2

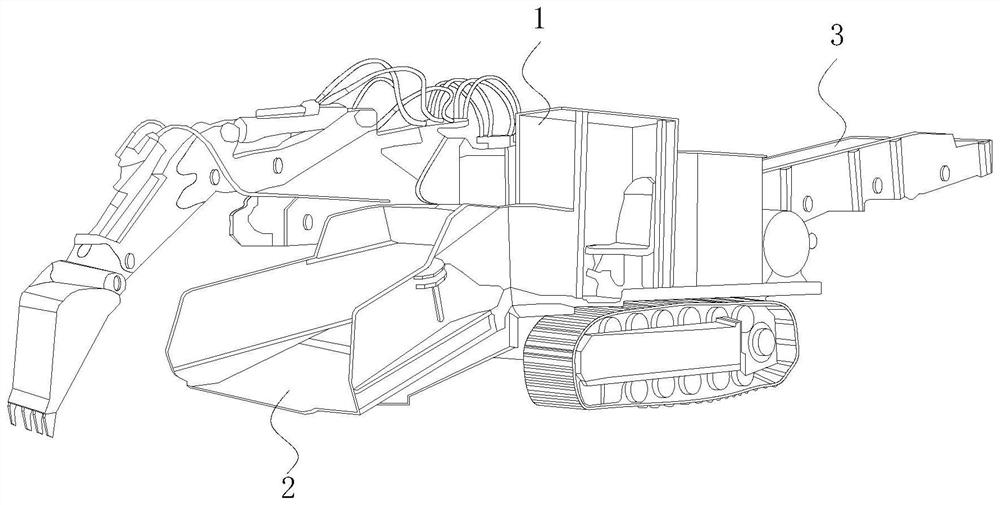

[0048] Such as figure 1 As shown, the present invention also provides an excavation loader, including a full-section rock-loading loading mechanism, and the full-section rock-loading loading mechanism is the full-section rock-loading loading mechanism described in any one of the above.

[0049] Please refer to the prior art for the structure of the body 1 part of the backhoe loader, which will not be described in detail herein.

[0050] Refer to Example 1 for other undescribed structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com