Black water regulating valve assembly

A black water regulating valve and assembly technology, which is applied in the direction of lifting valves, valve devices, valve details, etc., can solve the problems of not considering the purge structure, unable to regularly valve, short service life, etc., to improve the peeling effect and reduce the later period Maintenance cost and effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

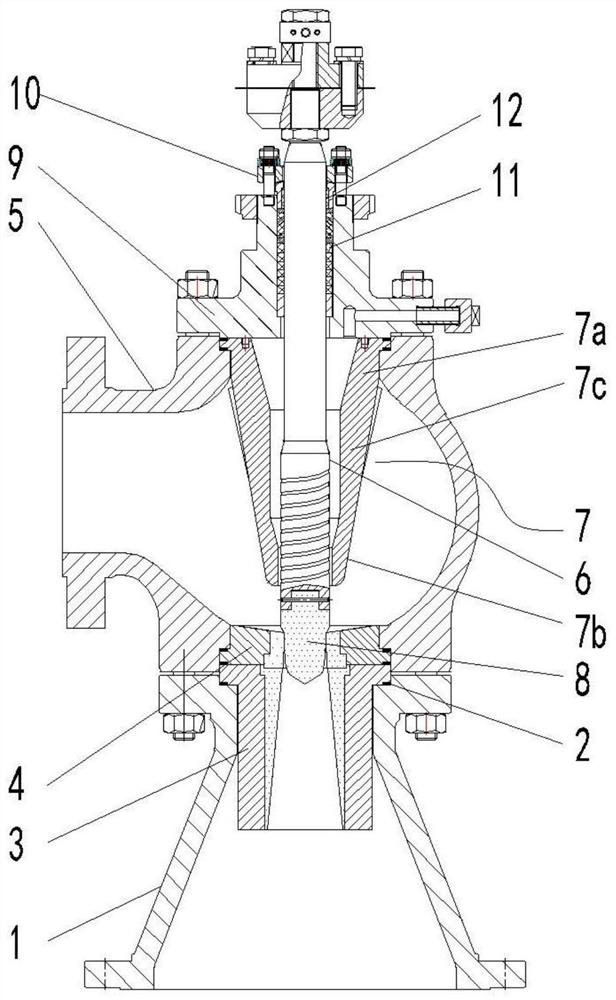

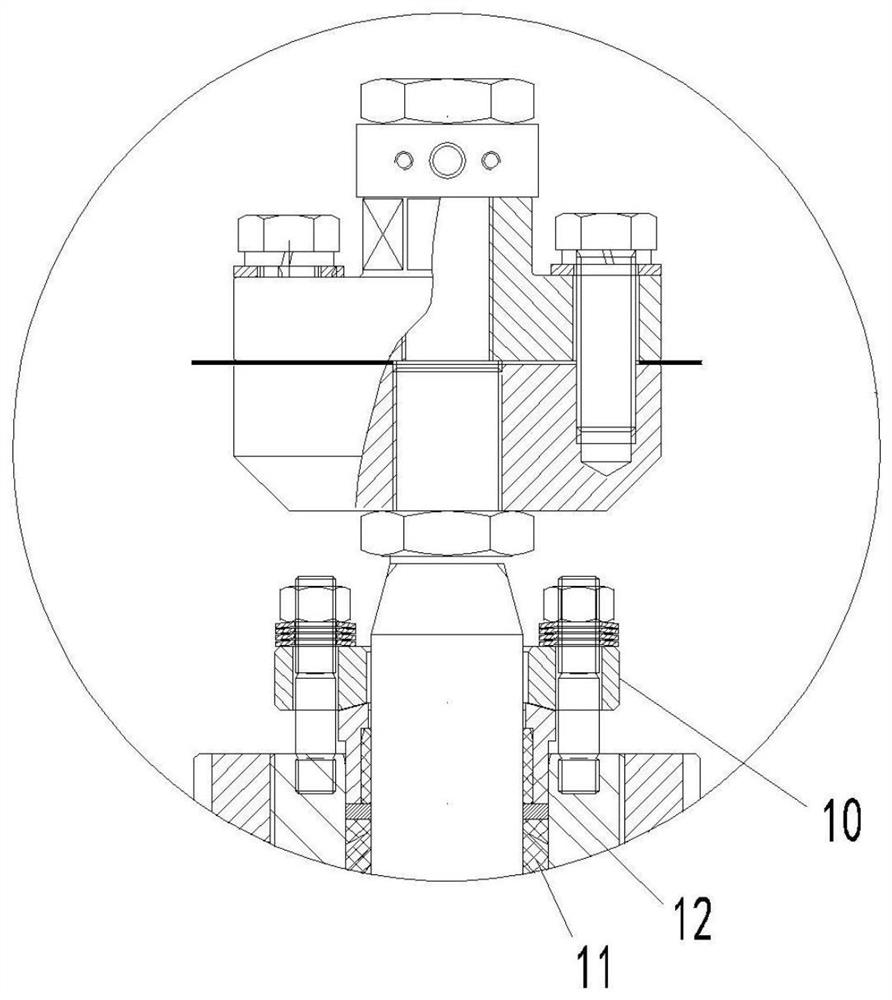

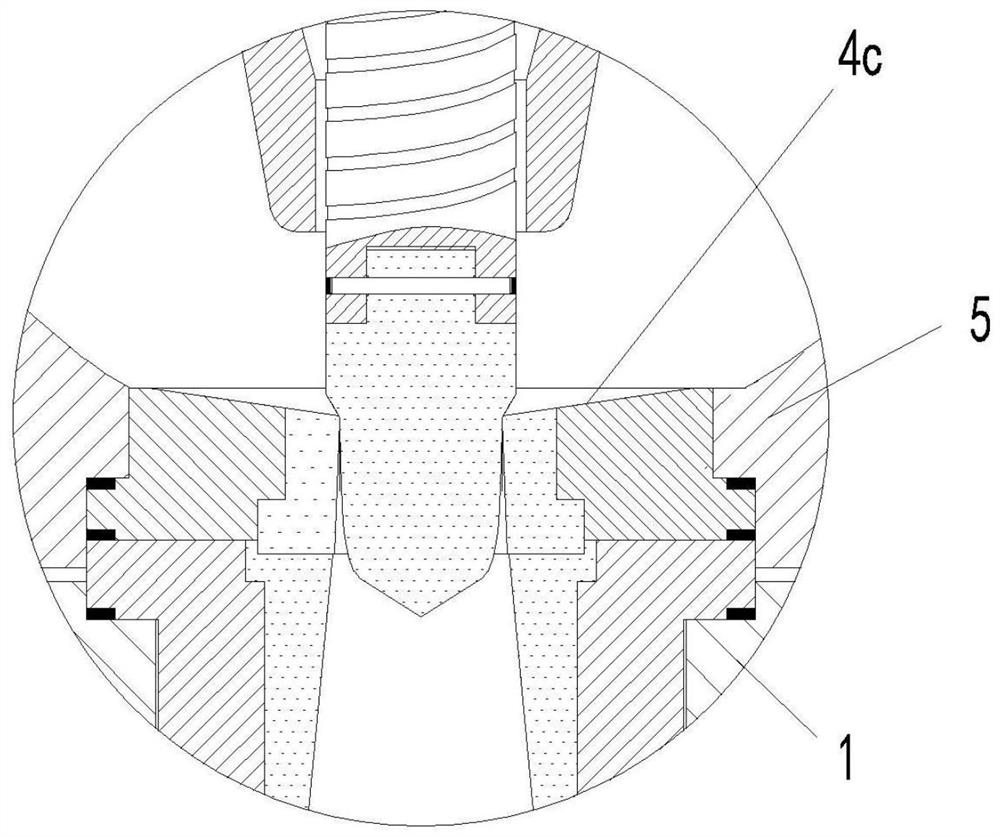

[0027] This embodiment provides a black water control valve assembly, as shown in the accompanying drawings, including a valve seat 4, a valve body 5, a valve seat ring 3, a guide ring 7, a valve stem 6, an upper valve cover 9 and a flange 1. The flange is connected to the outlet of the lower end of the valve body. The inner circle of the flange and the outer circle of the seat ring are sealed by a metal wound gasket 2. The valve core 8 is connected to the bottom of the valve stem. Slidingly fit with the guide ring, the valve stem drives the spool to insert into the valve seat to form a closed state or drive the spool to slide out of the valve seat to form an open state, the upper bonnet is sealed on the valve body, and the upper bonnet has a packing gland on the sealing cover 10. The packing gland presses the sealing packing 11 between the bonnet and the upper bonnet. A sliding bearing 12 is set between the packing gland and the valve stem. The lower end of the valve stem slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com