A high-precision synchronous position information calibration system and method based on a servo mechanism

A high-precision synchronization and servo mechanism technology, applied in the field of servo mechanisms, can solve the problem of insufficient synchronization accuracy of position information, and achieve the effects of high-precision synchronization, improved calibration efficiency and optimal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0025] This embodiment provides a high-precision synchronous position information calibration system and method based on a servo mechanism, which overcomes the defect of insufficient synchronization accuracy of position information between the product under test and the servo mechanism in the prior art, and uses a computer to realize the servo mechanism The output function of high-precision synchronous position information, using the external pulse triggering and latching functions corresponding to the dual-core of the high-precision counting board, adopts the method of split-core processing to simplify the servo control system and realize the position information between the servo mechanism and the product under test. high-precision synchronization to improve calibration efficiency.

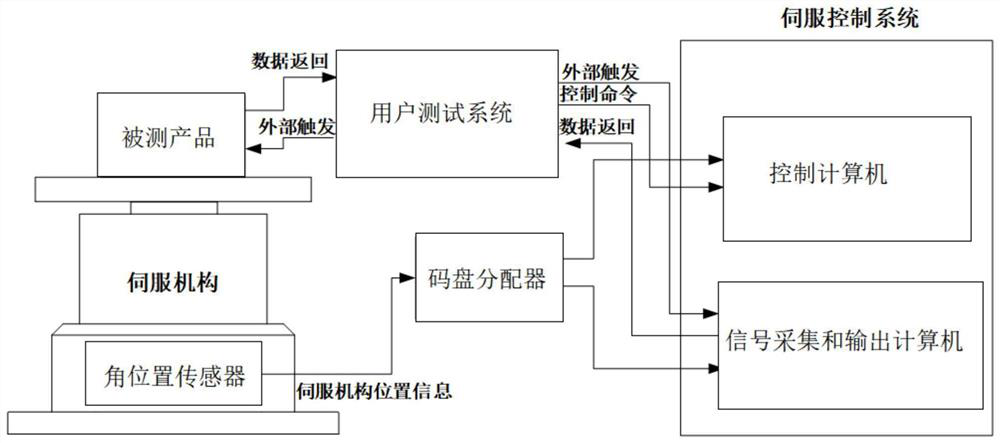

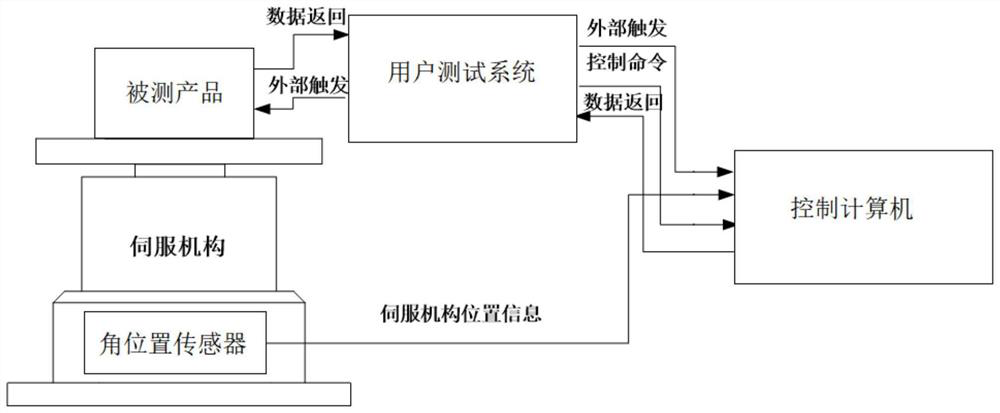

[0026] like figure 2 As shown, the high-precision synchronous posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com