Soft package lithium battery leakage detection method

A soft-packed lithium battery, leakage detection technology, applied in battery/battery leakage testing, by detecting the appearance of fluid at the leakage point, secondary battery repair/maintenance, etc., can solve battery leakage, low battery vacuum, Affect the appearance of the battery and other issues, to achieve the effect of battery detection

Inactive Publication Date: 2021-03-19

BOSHUO HAOYI AUTOMATION EQUIP WUXI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the production process of the soft-pack lithium battery, the leakage of the battery cell may be caused by reasons such as lax sealing and collision during the turnover process, or the vacuum degree in the battery cell is lower than the calibration value, resulting in defective products.

[0003] In the prior art, the leakage is detected by the pressure difference method, the surface of the battery is adsorbed by a suction cup, the cavity of the suction cup is vacuumed, and then the battery is leaked by visually checking whether there is a bulge on the surface of the battery, but this method will form a suction cup on the surface of the battery There is no method to eliminate the suction cup printing on the market, so the existing detection methods have the problem of affecting the appearance of the battery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

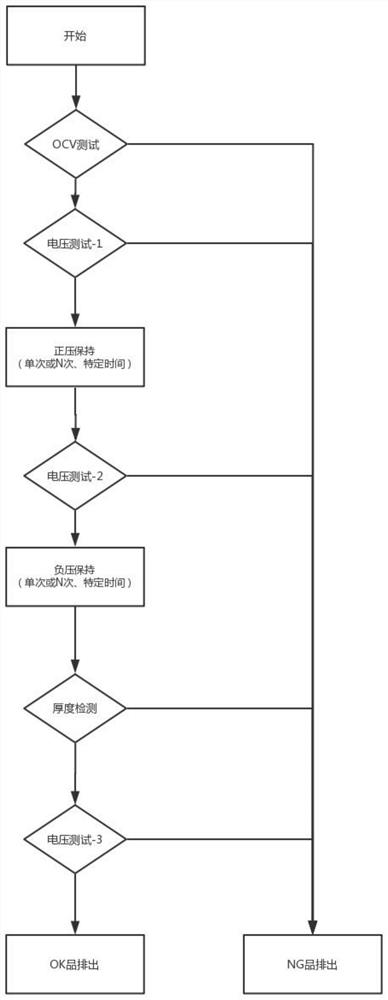

[0022] Embodiment: a method for detecting leakage of a soft pack lithium battery, comprising the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a soft package lithium battery leakage detection method which comprises the following steps: S1, putting a battery into a test cavity, performing OCV test on the battery, enabling the battery to enter the next process when the voltage is within the rated range of a client, and judging that the situation is ok, the voltage is abnormal and NG products are discharged; s2, performing a voltage test, recording a numerical value, enabling the battery to enter the next process when the voltage is within the rated range of the client, and judging ok, abnormal voltage and NG product discharge; and S3, quickly pumping negative pressure to the cavity to reach a certain negative pressure value, keeping for a certain time, detecting a change curve of the surface thickness of thebattery by virtue of a displacement sensor while pumping the negative pressure, and if the numerical value of each change point of the curve is close to that of the reference curve, entering the nextprocess of the battery and judging that ok, thickness abnormality and NG product discharge occur; and repeating the operation content of S2; by means of cooperation of negative pressure pumping and the displacement sensor, detection of the surface thickness change of the battery is achieved, and whether the battery is damaged or not is judged.

Description

technical field [0001] The invention relates to a battery leakage detection method, more specifically, it relates to a soft pack lithium battery leakage detection method. Background technique [0002] The proportion of aluminum-plastic film soft-pack batteries in power batteries is getting higher and higher. The packaging of soft-pack batteries is usually completed by heat-pressing the opening of the aluminum-plastic film packaging bag with a packaging machine. During the production process of the soft-pack lithium battery, the leakage of the battery cell may be caused by reasons such as lax sealing and collision during the turnover process, or the vacuum degree in the battery cell is lower than the calibration value, resulting in defective products. [0003] In the prior art, the leakage is detected by the pressure difference method, the surface of the battery is adsorbed by a suction cup, the cavity of the suction cup is vacuumed, and then the battery is leaked by visually...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M3/16G01B21/06H01M10/42

CPCG01B21/06G01M3/16H01M10/4228Y02E60/10

Inventor 曹盼盼于月

Owner BOSHUO HAOYI AUTOMATION EQUIP WUXI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com