Eccentricity adjusting structure and compressor with same

An eccentric adjustment and eccentric bushing technology, applied in the field of compressors, can solve problems such as low reliability of compressors, and achieve the effects of improving operational reliability, solving low reliability and avoiding jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

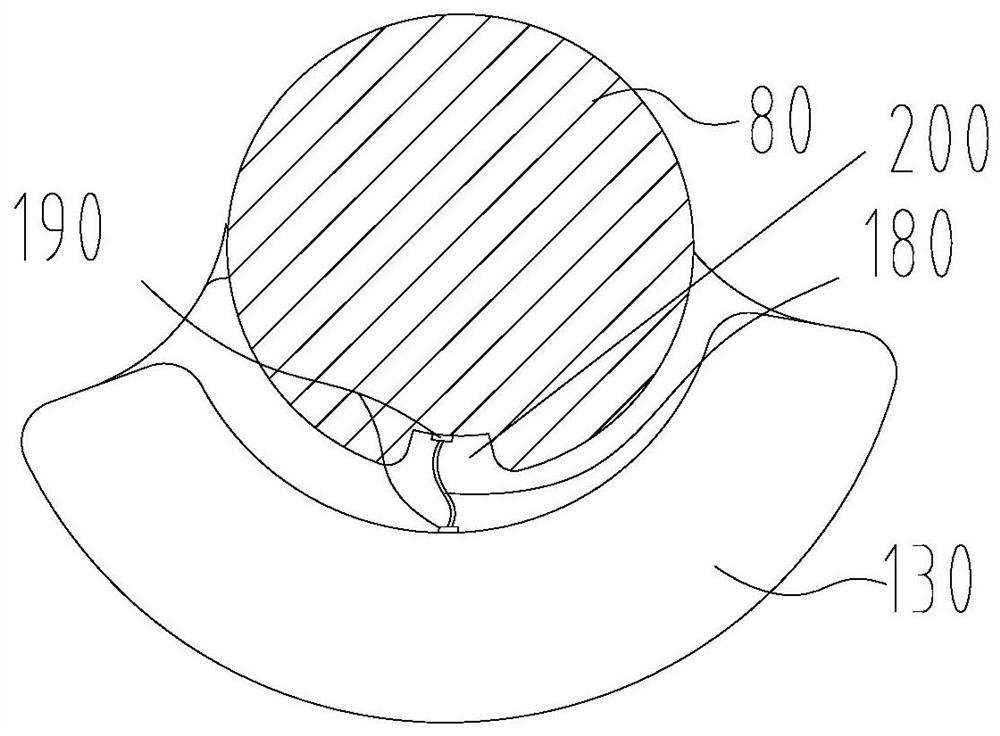

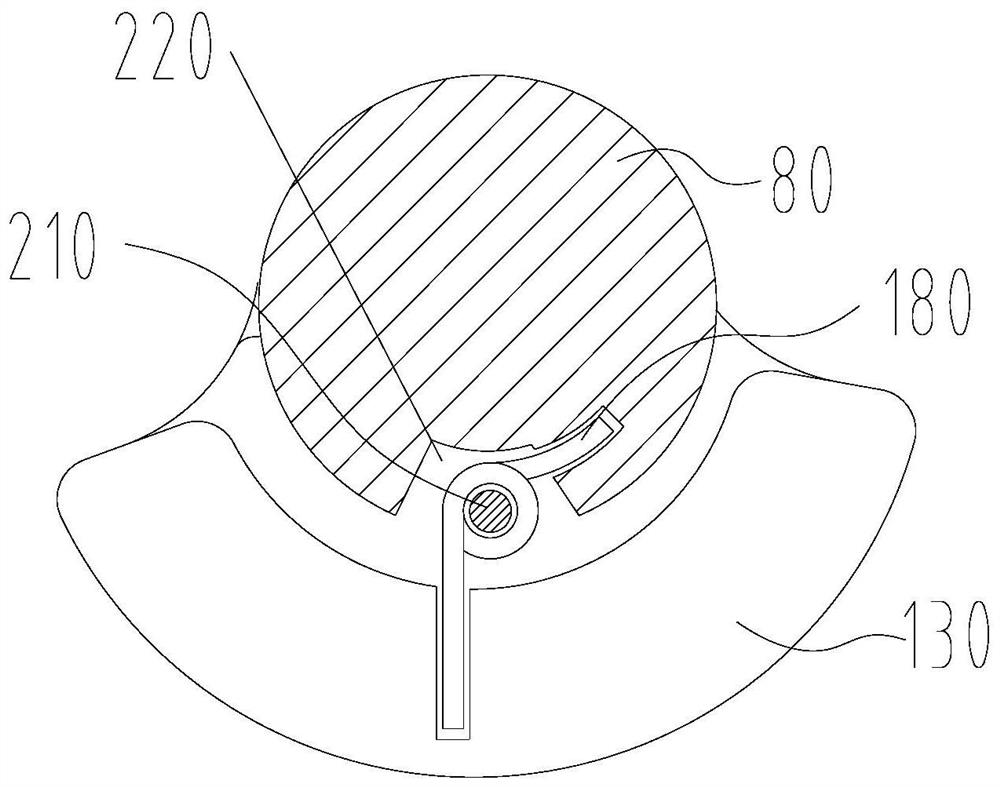

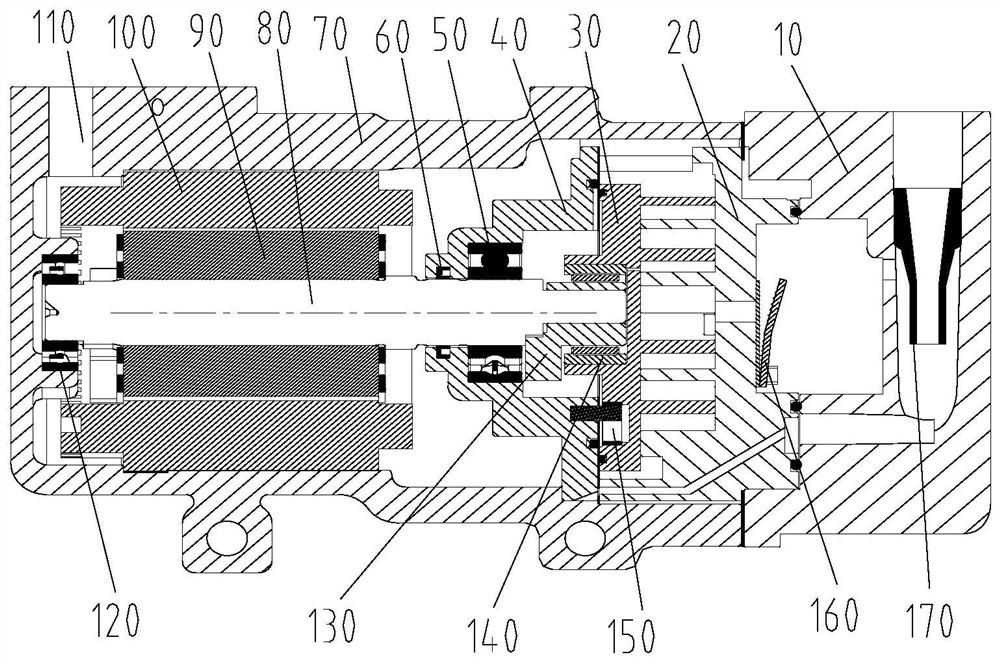

[0026] Such as figure 1 As shown, Embodiment 1 of the present invention provides an eccentric adjustment structure, and the eccentric adjustment structure includes: a drive shaft 80 , an eccentric bush 130 and a limiting member 180 . The drive shaft 80 is passed through the eccentric bushing 130, one end of the stopper 180 is connected to the drive shaft 80, the other end of the stopper 180 is connected to the eccentric bushing 130, and the stopper 180 is arranged on the drive shaft 80 and the eccentric bushing. Between the sleeves 130 , the relative rotation range between the drive shaft 80 and the eccentric bushing 130 is limited by the limiting member 180 .

[0027] With the eccentric adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com