Hydrogen liquefaction device with pre-cooling throttling function

A liquefaction device and pre-cooling technology, applied in refrigeration and liquefaction, liquefaction, cold treatment and separation, etc., can solve the problems of poor liquefaction effect of raw material hydrogen, affecting hydrogen production efficiency, etc., and achieve the effect of reducing irreversibility and enhancing thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

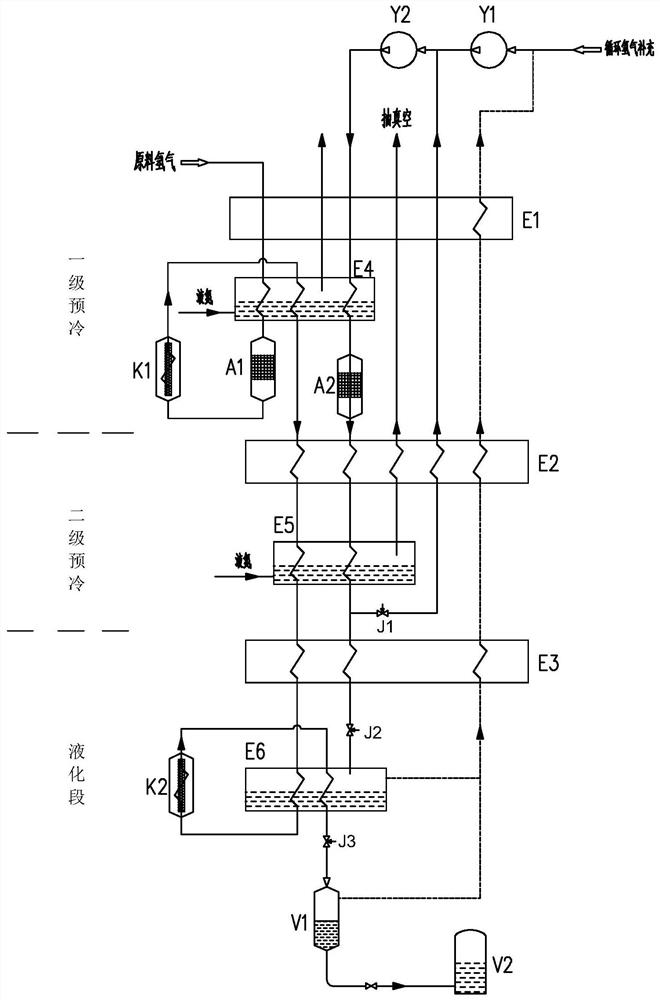

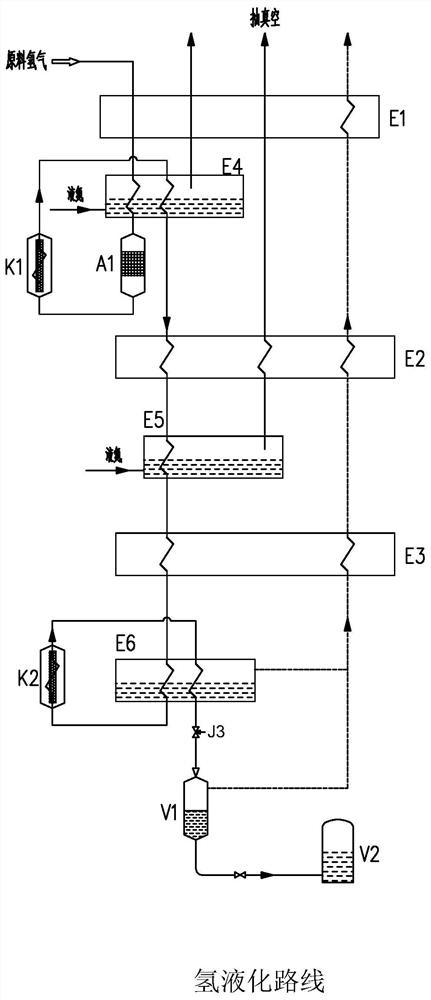

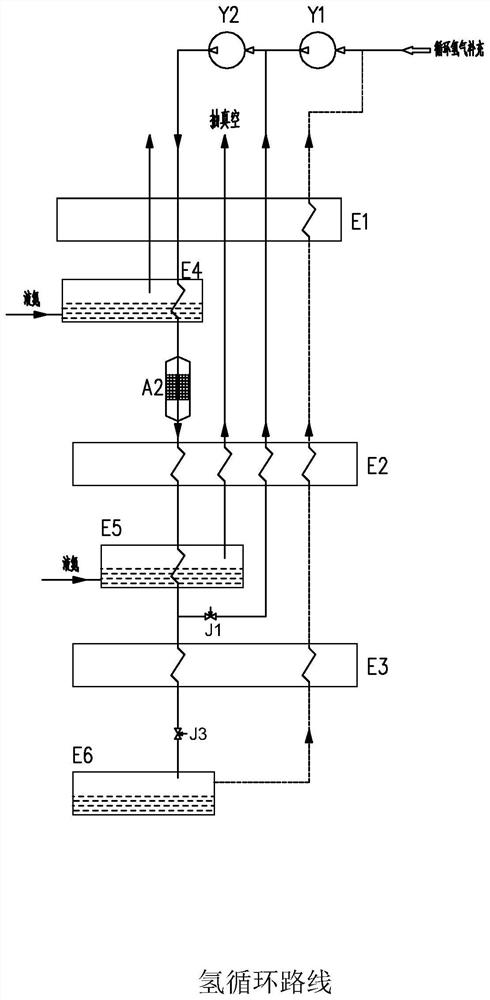

[0018] A hydrogen liquefaction device with precooling throttling, such as figure 1 As shown, it includes the hydrogen liquefaction route for transporting raw hydrogen and the hydrogen circulation route for transporting recycled hydrogen. The two routes respectively pass through the first-stage precooling section, the second-stage precooling section and the liquefaction section.

[0019] The primary pre-cooling section is equipped with a heat exchanger E1, an atmospheric pressure liquid nitrogen precooler E4, and an adsorber A1 and an adsorber II A2 for absorbing impurities in hydrogen. The pressure liquid nitrogen precooler E4 is connected to the atmosphere through the normal pressure pipeline, and the normal pressure pipeline passes through the heat exchanger one E1. Wherein, in order to improve and ensure the conversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com