A ni-mn-based ferromagnetic shape memory alloy and piezoelectric composite material with magnetic card effect and its application

A technology of memory alloy and magnetic card effect, applied in the direction of material selection, etc., can solve the problems of high width and narrow width, large hysteresis, half-height width and narrowness, etc., and achieve the effect of improving recovery and reducing hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

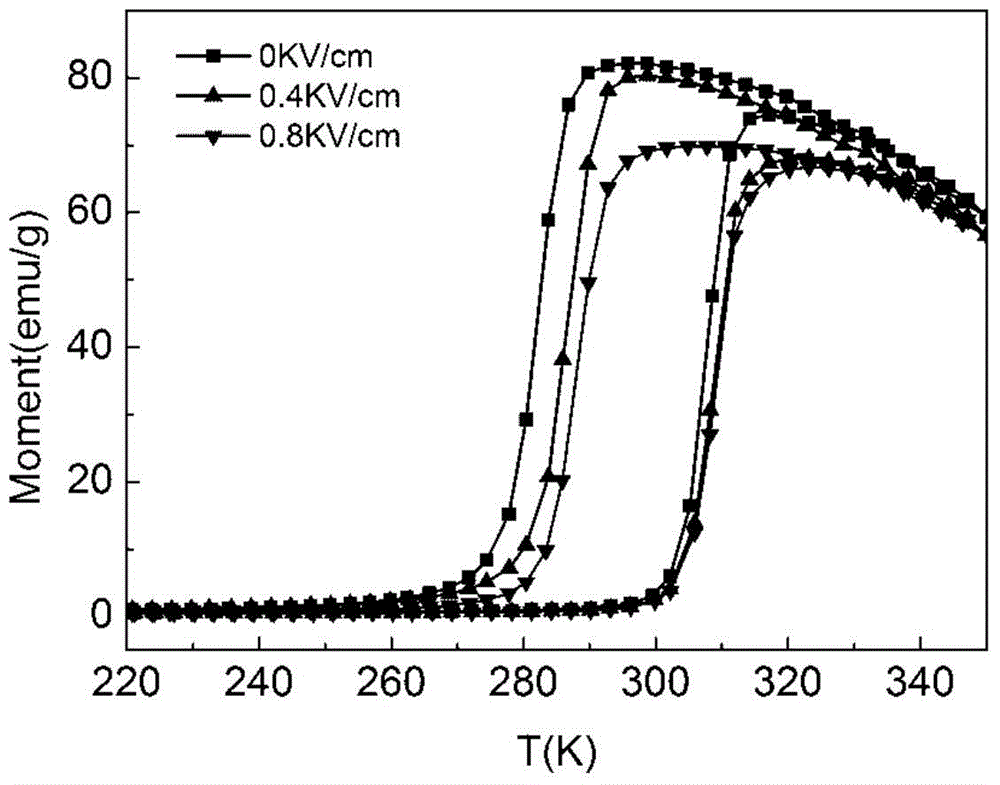

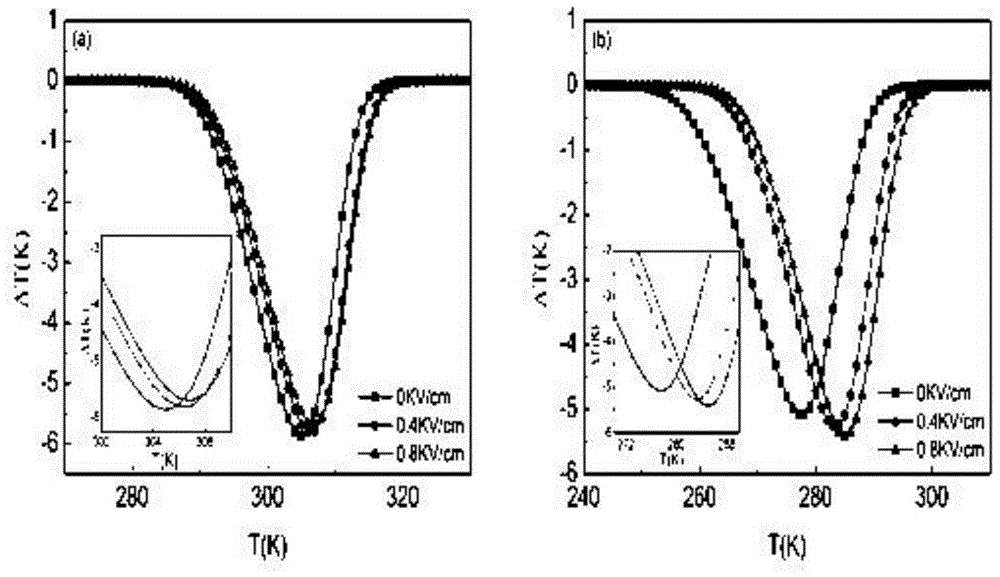

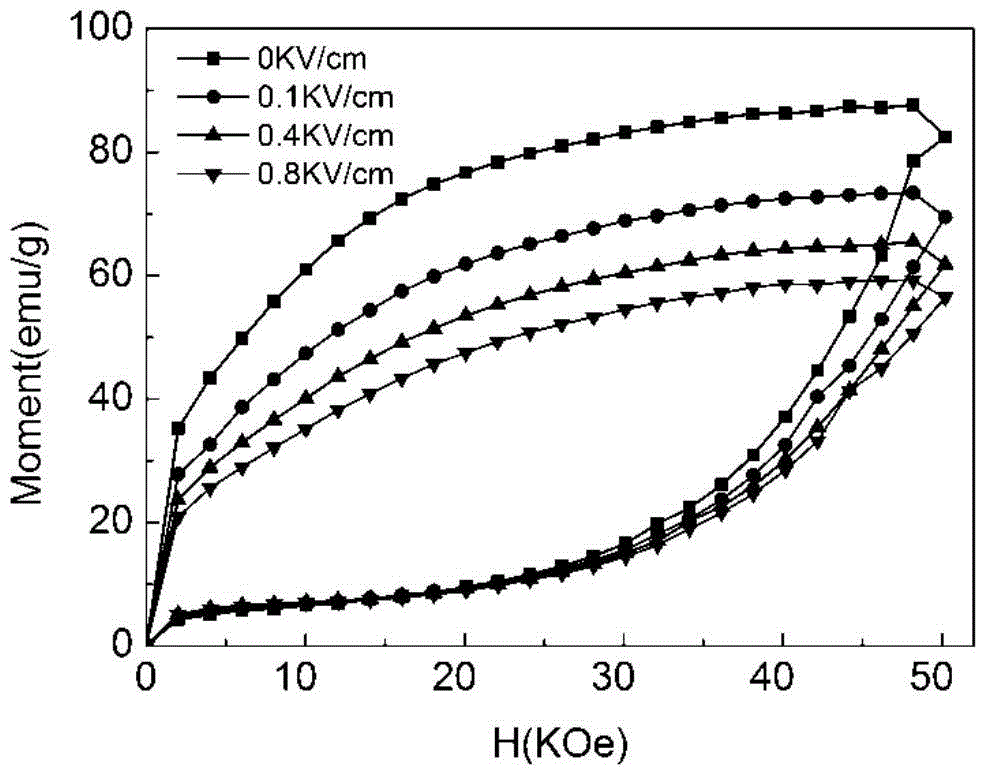

[0020] By applying a voltage to the piezoelectric body, the stress generated by the piezoelectric body acts on the Ni-Mn-based ferromagnetic shape memory alloy, and the stress affects its phase transition process, thereby changing the phase transition temperature and magnetic card effect. Experiments and theoretical calculations show that by applying different voltages to the piezoelectric body, the phase transition temperature of Ni-Mn-based ferromagnetic shape memory alloys changes, and the magnetic card effect also shifts laterally with the temperature axis as the phase transition temperature changes. Magnetic measurements show that hysteresis can be reduced and irreversibility can be reduced by applying different voltages during the lifting and lowering of the field.

[0021] The composite material is PMN / Ni-Co-Mn-In, and there is no essential difference in using Ni-Mn-In, Ni-Mn-Sn or Ni-Mn-Co-Sn. The two materials are laminated with s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com