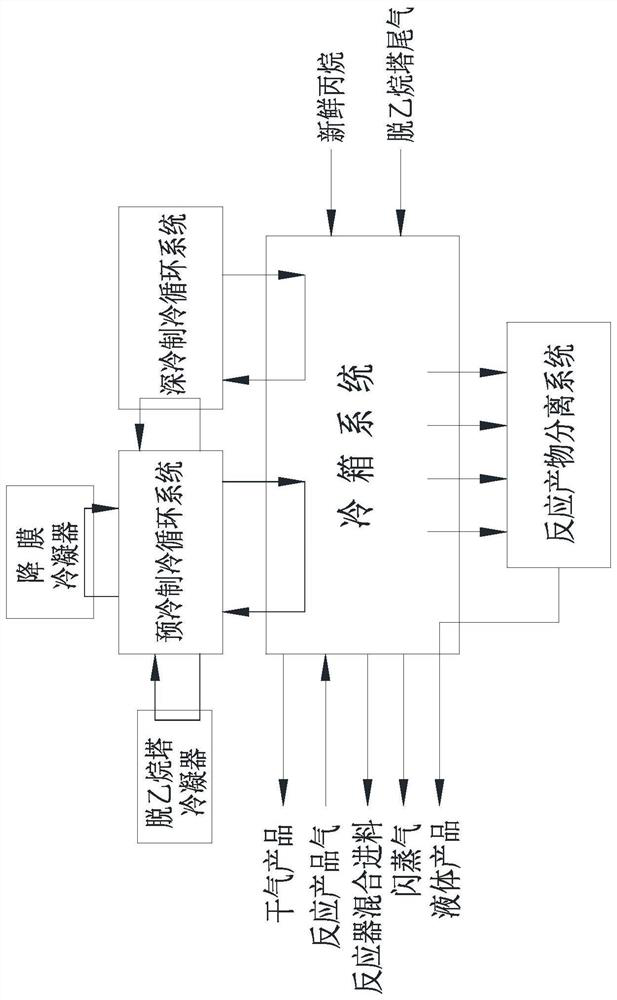

Separation method and device for coupling type alkane catalytic dehydrogenation reaction product

A technology for catalytic dehydrogenation and reaction products, applied in chemical instruments and methods, fractional condensation purification/separation, cold treatment separation, etc., can solve the problem of poor separation effect of propane dehydrogenation reaction gas, low C3 recovery rate, and complex unit. and other problems, to achieve the effect of saving separation energy consumption, reducing irreversibility and loss, and reducing separation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

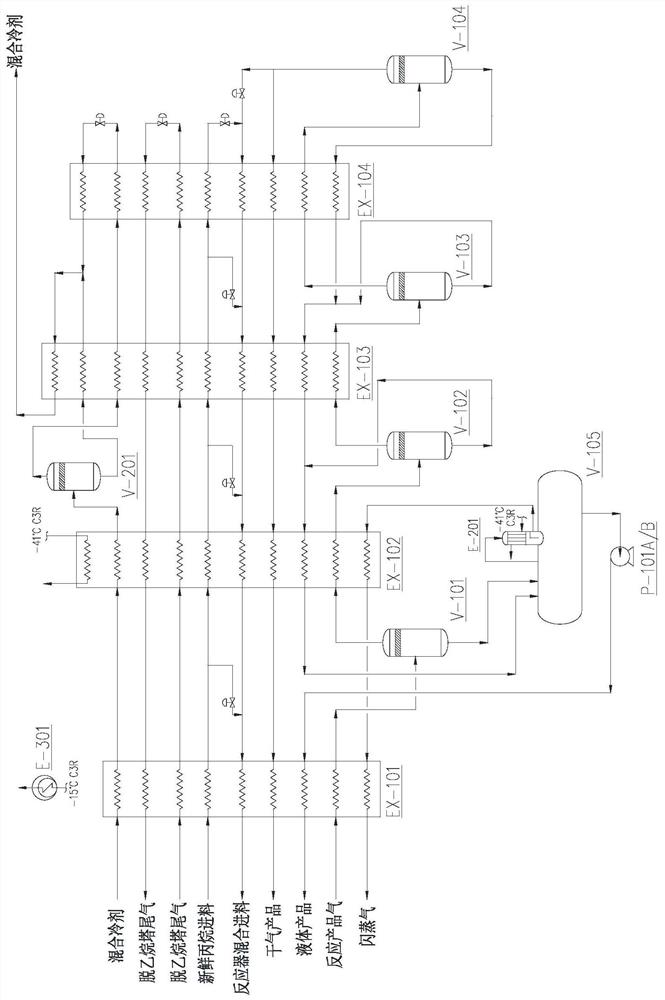

[0061] like figure 2 As shown in the figure, the reaction product gas at the outlet of the propane dehydrogenation reactor enters the separation system plate-fin heat exchanger EX-101 after pretreatment such as cooling, compression, purification and filtration. Separation tank V101, the separated liquid phase enters the carbon three product tank V-105, and the gas phase enters the plate-fin heat exchanger EX-102 for further cooling and condensing to -38 ℃ and then enters the gas-liquid separation tank V-102. After the phase carbon three is mixed with the liquid phase carbon three separated from the next stage, it is reheated in the plate-fin heat exchanger EX-102 and aggregated to the carbon three product tank V-105 by its own pressure, and the gas phase enters the plate-fin heat exchange. After further cooling and condensation in the heat exchanger EX-103, it enters the gas-liquid separation tank V-103. The separated liquid phase carbon three is separated from the next stage...

Embodiment 2

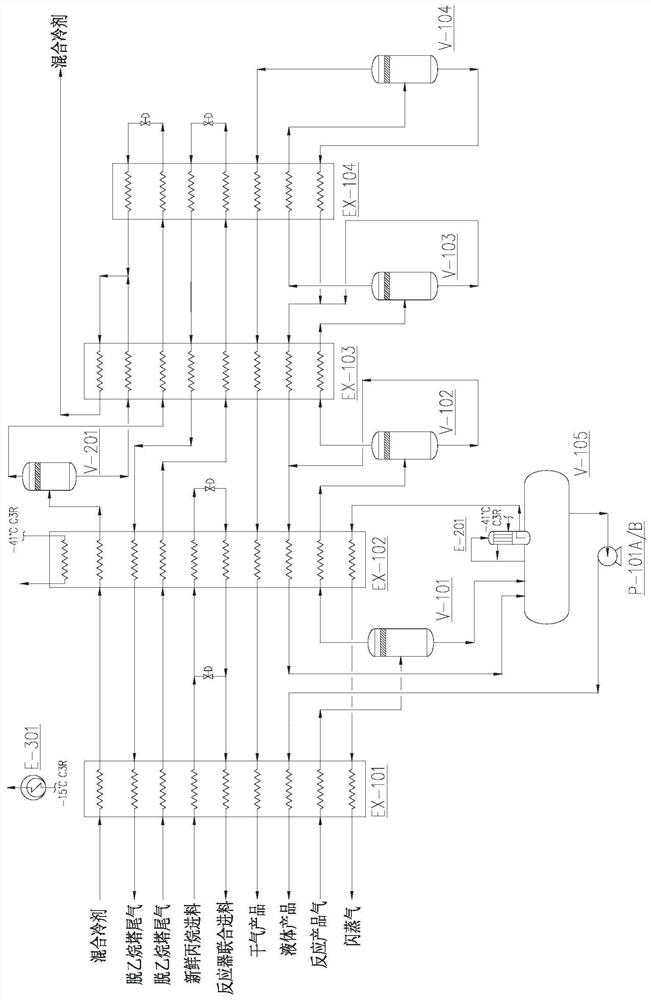

[0066] like image 3 As shown in the figure, the reaction product gas at the outlet of the propane dehydrogenation reactor enters the separation system plate-fin heat exchanger EX-101 after pretreatment such as cooling, compression, purification and filtration. Separation tank V101, the separated liquid phase enters the carbon three product tank V-105, and the gas phase enters the plate-fin heat exchanger EX-102 for further cooling and condensing to -37°C and then enters the gas-liquid separation tank V-102. After the phase C3 is mixed with the liquid C3 separated from the next stage, it is reheated in EX-102 and collected to the C3 product tank V-105 by its own pressure, and the gas phase enters the plate-fin heat exchanger EX-103 for further cooling After condensing, it enters the gas-liquid separation tank V-103, and the separated liquid-phase carbon three is mixed with the liquid-phase carbon three separated from the next stage and reheated in the plate-fin heat exchanger ...

Embodiment 3

[0071] like Figure 4 As shown, the reaction product gas at the outlet of the propane dehydrogenation reactor enters the separation system plate-fin heat exchanger EX-101 after pretreatment such as cooling, compression, purification and filtration. Separation tank V101, the separated liquid phase enters the carbon three product tank V-105, and the gas phase enters the plate-fin heat exchanger EX-102 for further cooling and condensing to -30 ℃, and then enters the gas-liquid separation tank V102, the separated liquid phase carbon The carbon three separated from the next stage and reheated in the plate-fin heat exchanger EX-103 is mixed, and then reheated in the plate-fin heat exchanger EX-102 and aggregated to the carbon three product by its own pressure Tank V-105, the gas phase enters the plate-fin heat exchanger EX-103, and after cooling to -130 ℃, it enters the gas-liquid separation tank V-103. The dry gas and circulating gas are obtained at the top of the final gas-liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com