Assembly type steel structure cross beam strength detection device and detection method

A strength detection and steel structure technology, applied in the direction of using a stable shear force to test the material strength, using a stable bending force to test the material strength, etc. Reliable flexural strength and shear strength index, easy operation and strong testing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

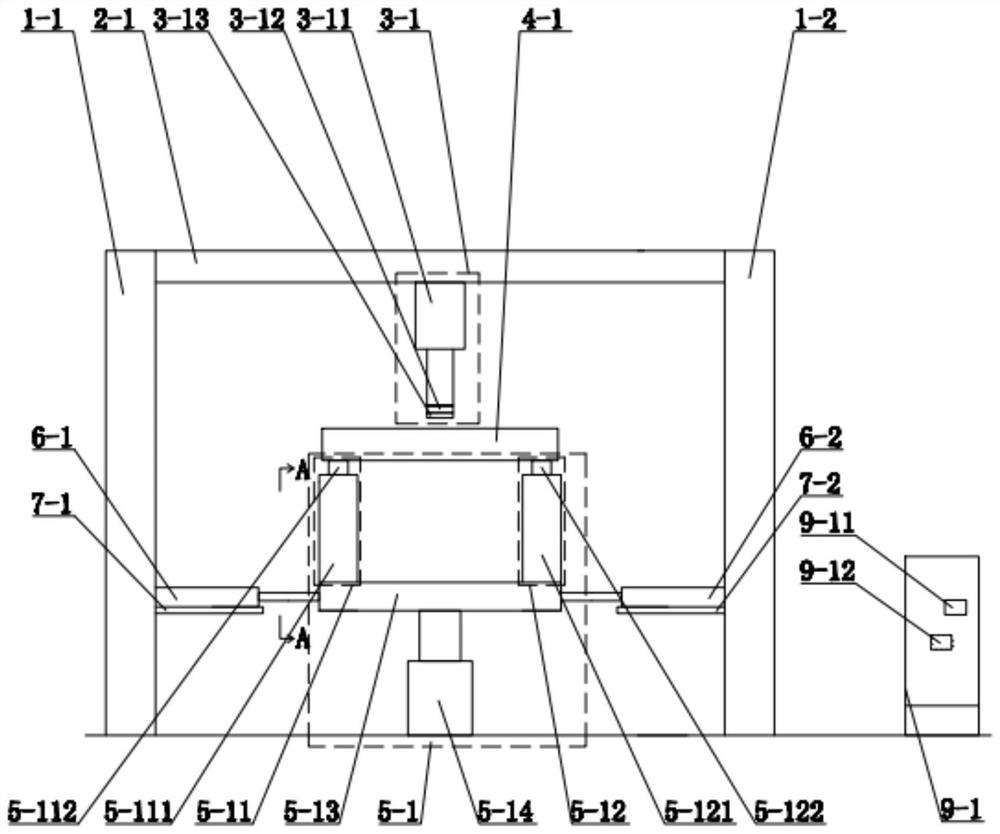

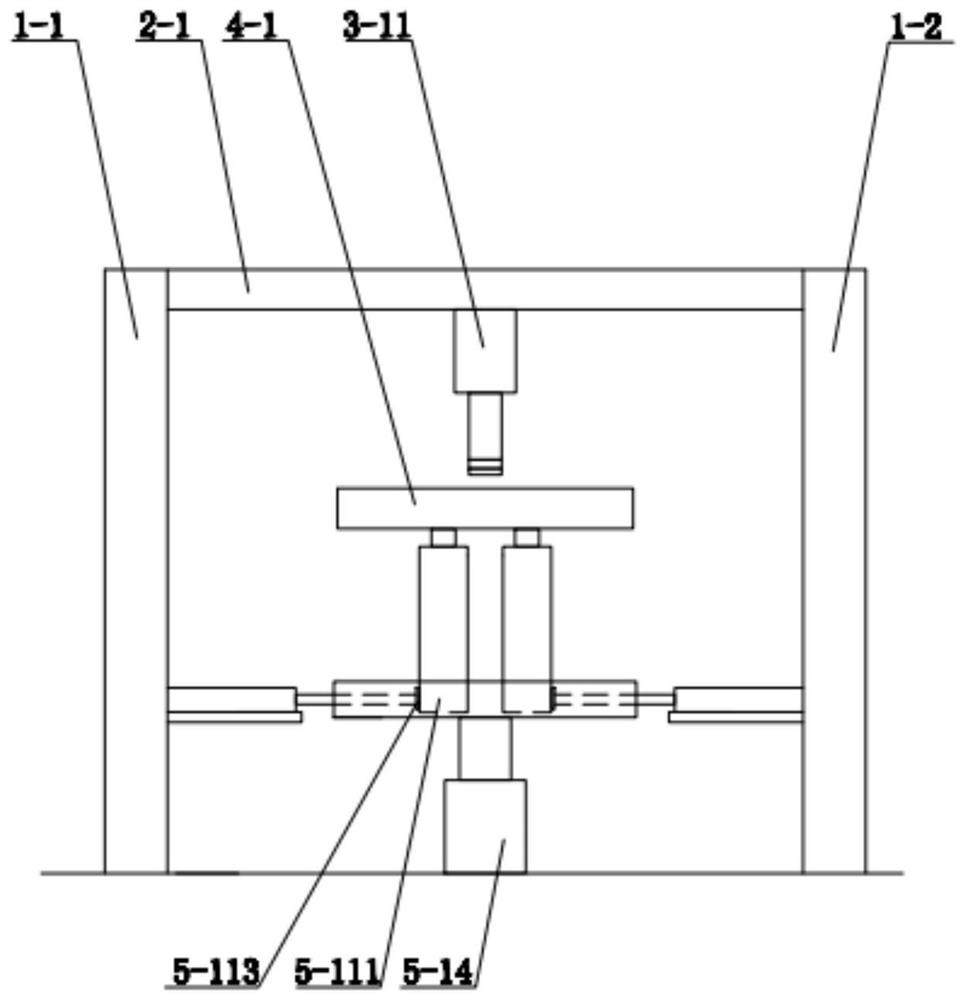

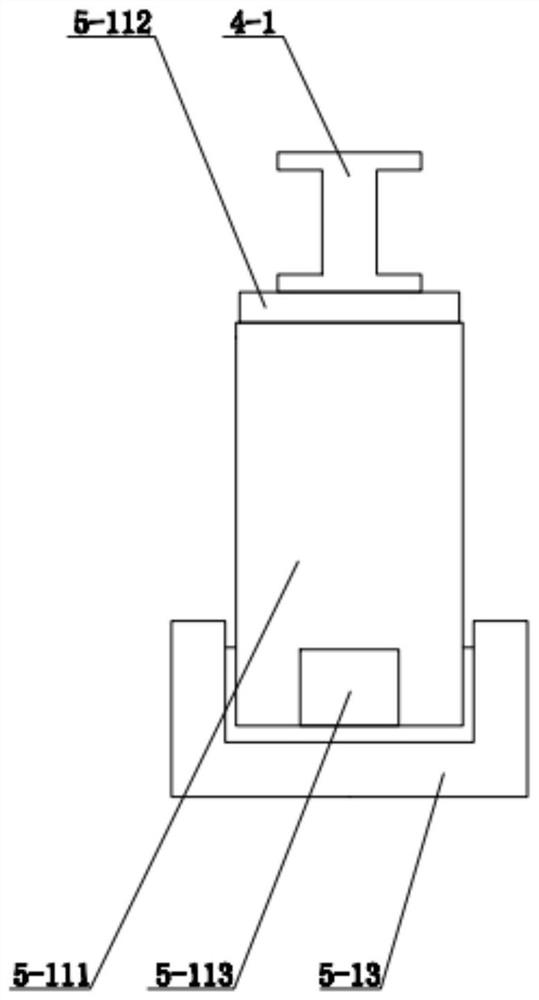

[0027] see figure 1 , Figure 3-Figure 4As shown, the technical solution adopted in the specific embodiment of the present invention is: it comprises left column 1-1, right column 1-2, installation beam 2-1, loading device assembly 3-1, support assembly 5-1, left support assembly 5-11, left push oil cylinder 6-1, right push oil cylinder 6-2, left support plate 7-1, right support plate 7-2, strain gauge 8-1, first strain rosette 8-2, second strain rosette 8-3 and the control cabinet 9-1, the left side of the installation beam 2-1 is connected to the left column 1-1, the right side of the installation beam 2-1 is connected to the right column 1-2, and the loading device assembly 3-1 Including a loading device 3-11, a force sensor 3-12 and a pad 3-13, the loading device 3-11 is arranged under the installation beam 2-1, and the force sensor 3-12 is arranged on the loading device 3-12 11 front end, the pad 3-13 is arranged on the front end of the force sensor 3-12, the pad 3-13 i...

Embodiment 2

[0041] see Figure 2-Figure 3 , The technical scheme adopted in the specific embodiment of the present invention is compared with Example 1, except that the strain gauge 8-1, triaxial rosette 8-2 and right-angle rosette 8-3 are not included, other structures are the same as in Example 1.

[0042] A method for detecting the strength of an assembled steel structure beam according to the present invention comprises the following steps:

[0043] 1) Shear performance testing of fabricated steel structure beams;

[0044] In step 1), adjust the position of the support assembly, place the steel beam on the support assembly, make the loading device face the space between the two support assemblies, and then slowly pressurize the loading device until the steel beam is cut off, and read the maximum The loading load Q max , according to the shear stress formula where S is the cross-sectional area of the steel beam.

[0045] Working principle: By adjusting the position of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com