Lawn laying equipment

A kind of equipment and lawn technology, which is applied in the field of lawn laying equipment, can solve the problems of tight fit of soil, difficulty in rooting, uneven lawn strength, etc., and achieve the effect of complete scratching of equipment and reduction of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

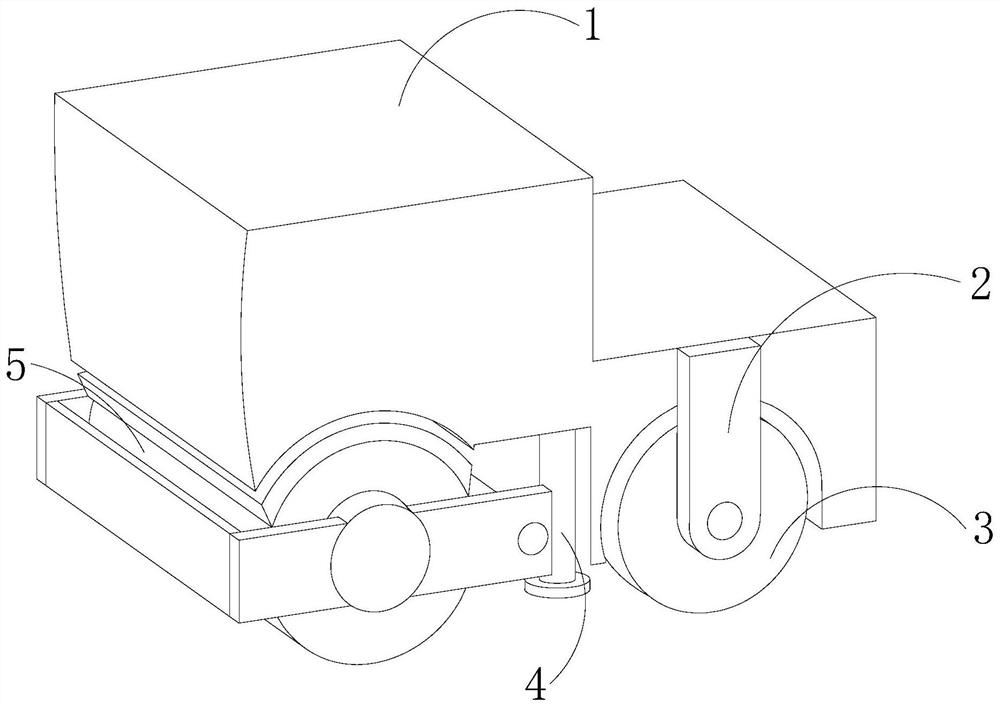

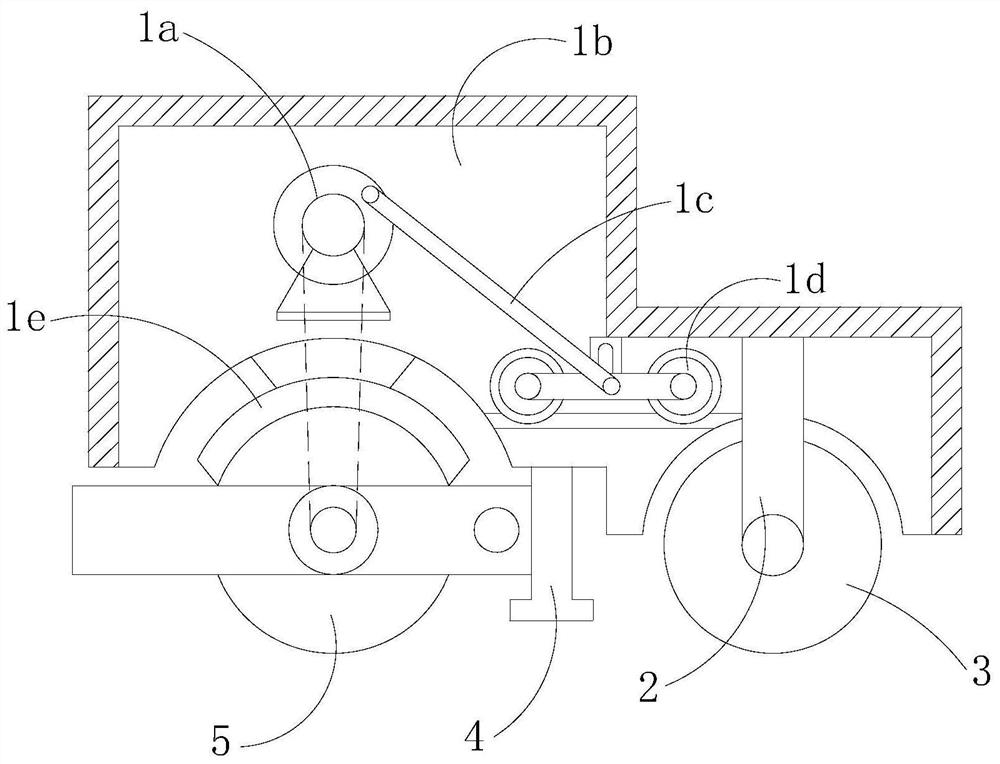

[0028] see Figure 1-Figure 5 , a lawn laying equipment, its structure includes an operator 1, a driving rod 2, a driving wheel 3, a bracket 4, and a rolling block 5, the operator 1 is embedded and connected with the driving rod 2, and the driving rod 2 moves The shaft is movably connected to the driving wheel 3, the manipulator 1 is fixedly connected to the bracket 4, and the rolling block 5 is mechanically connected to the manipulator 1;

[0029] The manipulator 1 is provided with a driven wheel 1a, a box body 1b, a connecting rod 1c, a gear 1d, and a leveler 1e. The driven wheel 1a is movably engaged with the box body 1b, and the connecting rod 1c is connected to the gear 1d through a movable shaft. Flexible connection, the leveler 1e is mechanically connected with the box body 1b to remove soil clods on the rolling structure.

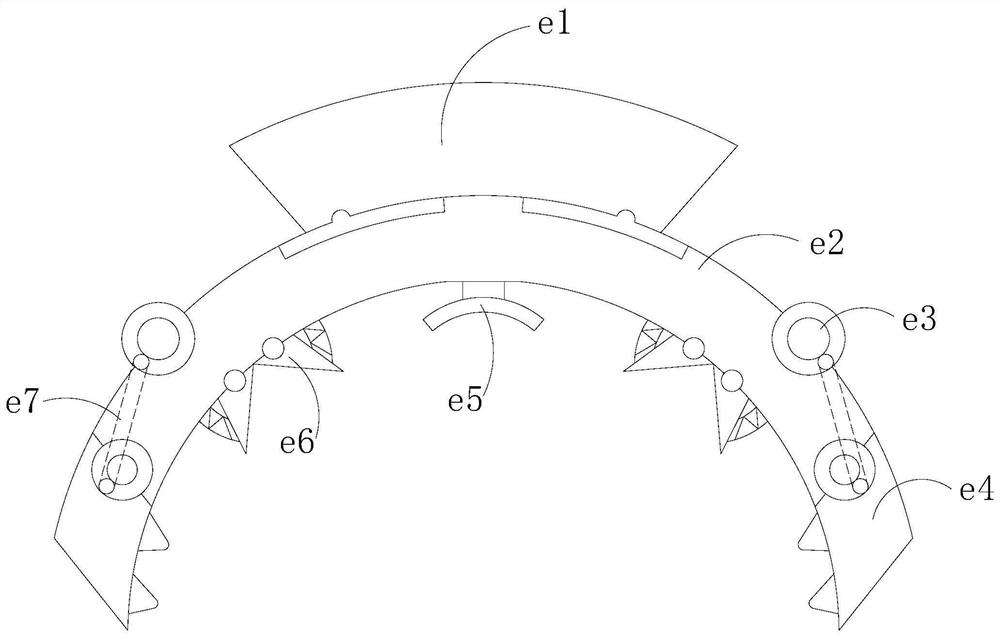

[0030] The leveler 1e is provided with a snapper e1, a fitting shaft e2, a ring shaft e3, a knocking body e4, a scratcher e5, a hook block e6, and...

Embodiment 2

[0038] see Figure 1-Figure 6 , a lawn laying equipment, its structure includes an operator 1, a driving rod 2, a driving wheel 3, a bracket 4, and a rolling block 5, the operator 1 is embedded and connected with the driving rod 2, and the driving rod 2 moves The shaft is movably connected to the driving wheel 3, the manipulator 1 is fixedly connected to the bracket 4, and the rolling block 5 is mechanically connected to the manipulator 1;

[0039] The manipulator 1 is provided with a driven wheel 1a, a box body 1b, a connecting rod 1c, a gear 1d, and a leveler 1e. The driven wheel 1a is movably engaged with the box body 1b, and the connecting rod 1c is connected to the gear 1d through a movable shaft. Flexible connection, the leveler 1e is mechanically connected with the box body 1b to remove soil clods on the rolling structure.

[0040] The leveler 1e is provided with a snapper e1, a fitting shaft e2, a ring shaft e3, a knocking body e4, a scratcher e5, a hook block e6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com