Cigar-shaped tea and shaping equipment thereof

A technology of cigar tea and equipment, which is applied in the field of cigar tea and its shaping equipment, which can solve the problems of tea taste reduction, tea aroma interference, waste of storage space, etc., and achieve the effect of improving utilization rate, retaining aroma, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

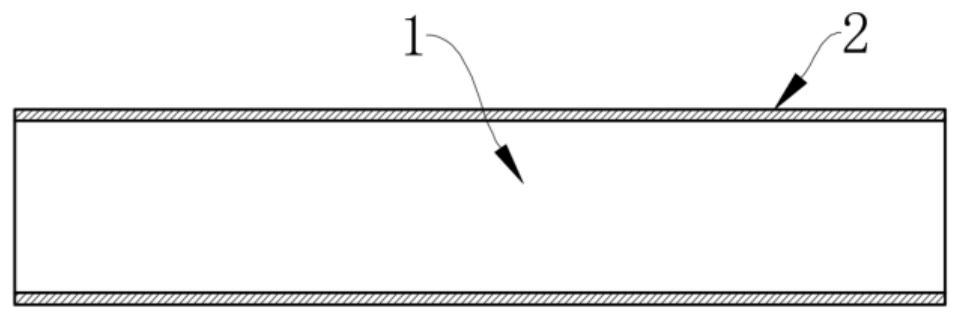

[0028] like figure 1 As shown, the present embodiment provides a kind of cigar tea, comprising a cylindrical tea core 1 made of dry tea leaves, and fresh tea leaves 2 wrapped around the tea core to form a cigar tea in a shape similar to a cigar, improving storage space. Utilization rate, retain the aroma of tea, and realize the maximum retention of the substances contained in the tea.

Embodiment 2

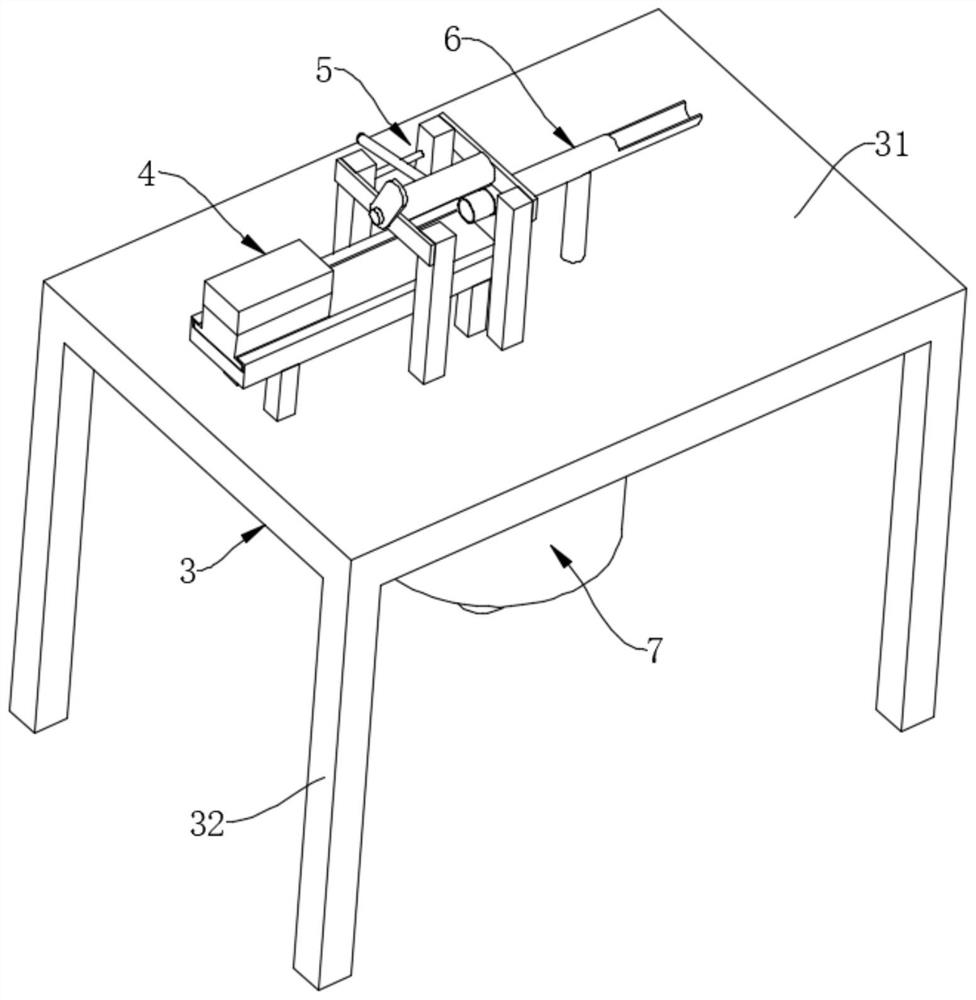

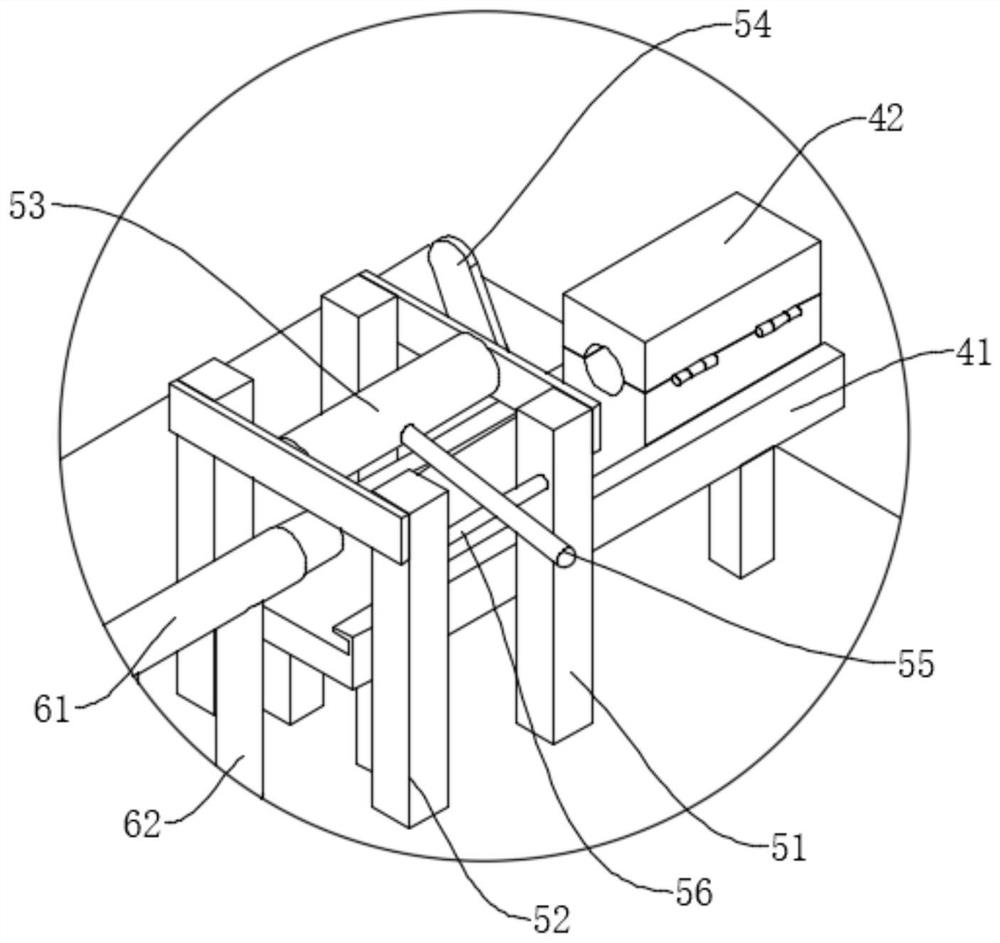

[0031] like figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, this embodiment provides a cigar tea sizing device for making the above-mentioned tea core 1, the sizing device specifically includes a base 3, the base 3 includes a support plate 31 and support legs arranged at the bottom of the support plate 31 32 ; the top of the support plate 31 is provided with a shaping device 4 , a limiting device 5 and a feeding device 6 .

[0032] Specifically, the above-mentioned sizing device 4 includes a track 41 and a sizing block 42 that can slide along the track 41. A mounting hole is provided inside the sizing block 42, and an end of the mounting hole close to the feeding device 6 passes through the outer wall of the sizing block 42, and The other end of the mounting hole is closed; the mounting hole is provided with a cylindrical mold 43 adapted to it, the two ends of the mold 43 are open, and the inner circumference of the mold 43 is adapted to the outer circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com