Metal powder spray head equipment

A metal powder and equipment technology, applied in the field of metal powder molding equipment, can solve the problems of lack of precision, inability to adjust the amount of metal powder sprayed at the end, and the actual working efficiency of the equipment, etc., and achieve the effect of simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

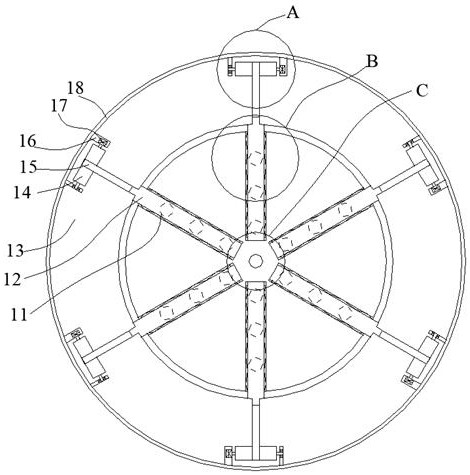

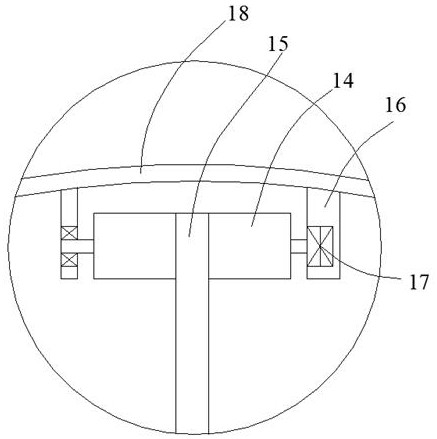

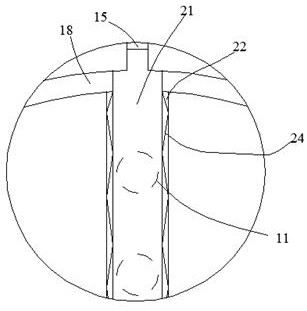

[0026] like Figure 1-Figure 7 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship are the same. The metal powder spray head equipment of the present invention includes a matching cylinder 18, and a ring cavity 13 is arranged inside the matching cylinder 18, and a number of drop holes are connected in the matching cylinder 18. Holes 11, the drop holes 11 are arranged in an annular array, and a pumping device for pumping out metal powder is provided on one side of the drop holes 11, and a plurality of sliding stops are arranged on the ring cavity 13 and the sliding inside the cylinder body 18. The plate 12, the matching cylinder 18 and the ring cavity 13 are provided with a spout opening and closing device that drives the sliding baffle 12 to move the falling hole 11 at different posi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap