Novel transverse adjustment mechanism for side form of segmental box girder

A technology of lateral adjustment mechanism and segment, applied in ceramic molding machines, molds, auxiliary molding equipment, etc., can solve the problems of inconvenient disassembly of workpieces, inconvenient support work of segment boxes, inconvenient adjustment of the position of side molds, etc. Easy to adjust the effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

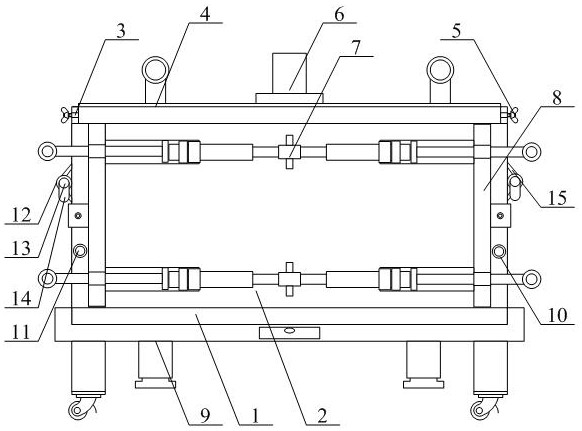

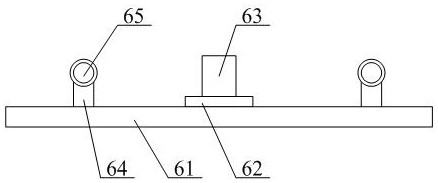

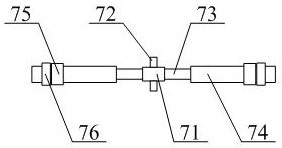

[0035] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown in the figure, a lateral adjustment mechanism of the side form of a new segmental box girder includes a segmental box body 1, a pouring cavity 2, a threaded hole 3, an insertion hole 4, a jacking bolt 5, and a pouring cover structure 6 that can be hoisted. Fixed support rod structure 7, plug-in adjustable side cover structure 8, movable horizontal detection seat structure 9, jacking rod 10, threaded pipe 11, connecting ring 12, insertion rod 13, hoisting frame 14 and diagonal brace rod 15, The pouring cavity 2 is set at the middle position inside the section box body 1; the threaded holes 3 are set at the upper middle positions on the left and right sides of the section box body 1; The middle position of the upper end of the section box body 1; the jacking bolts 5 are threadedly connected to the inside of the threaded holes 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com