Iron handicraft manufacturing equipment

A handicraft and equipment technology, applied in the field of iron handicraft production equipment, can solve the problems of inconvenient carrying and single form, and achieve the effect of convenient carrying and diversified winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

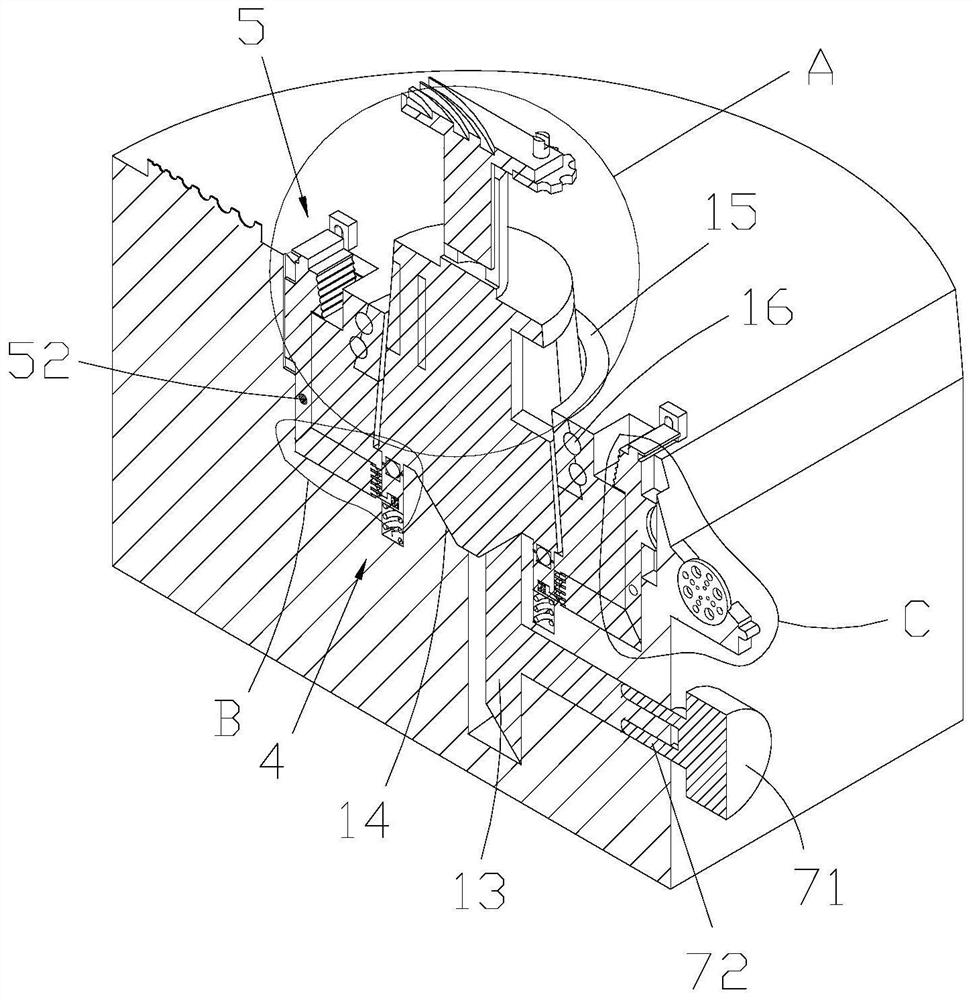

[0025] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

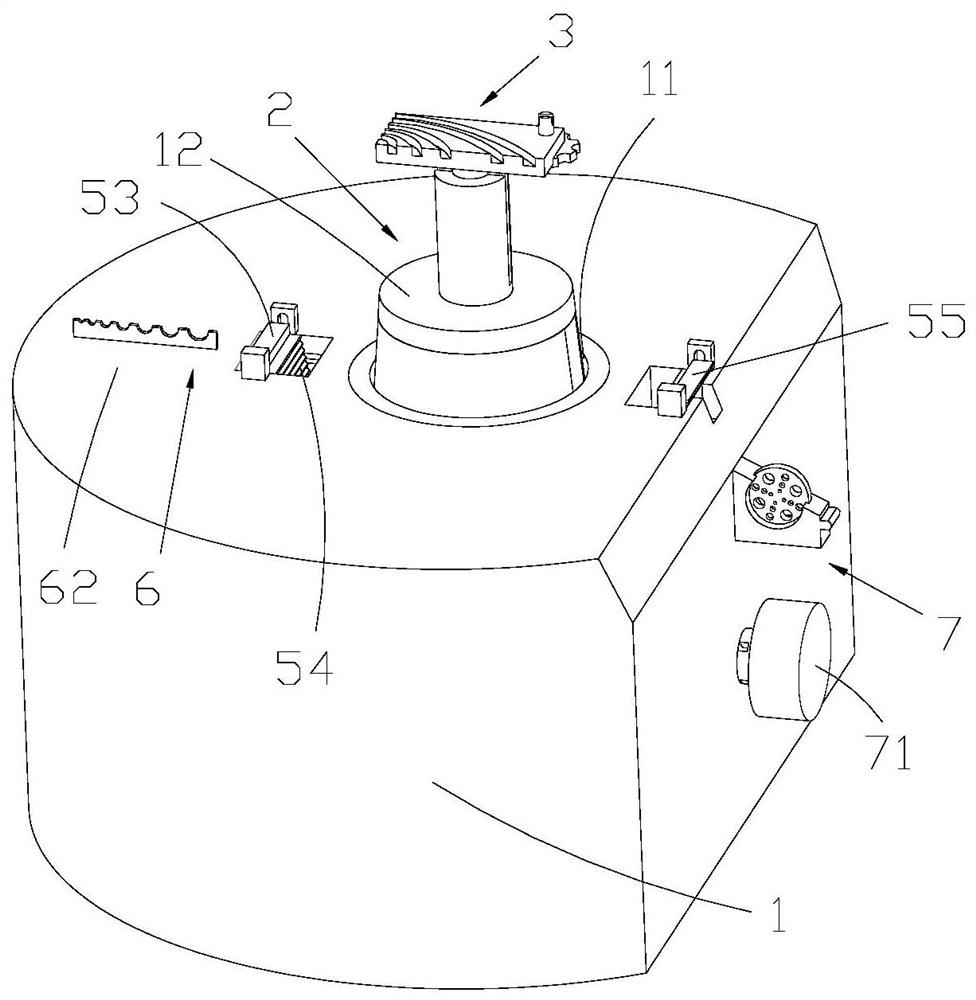

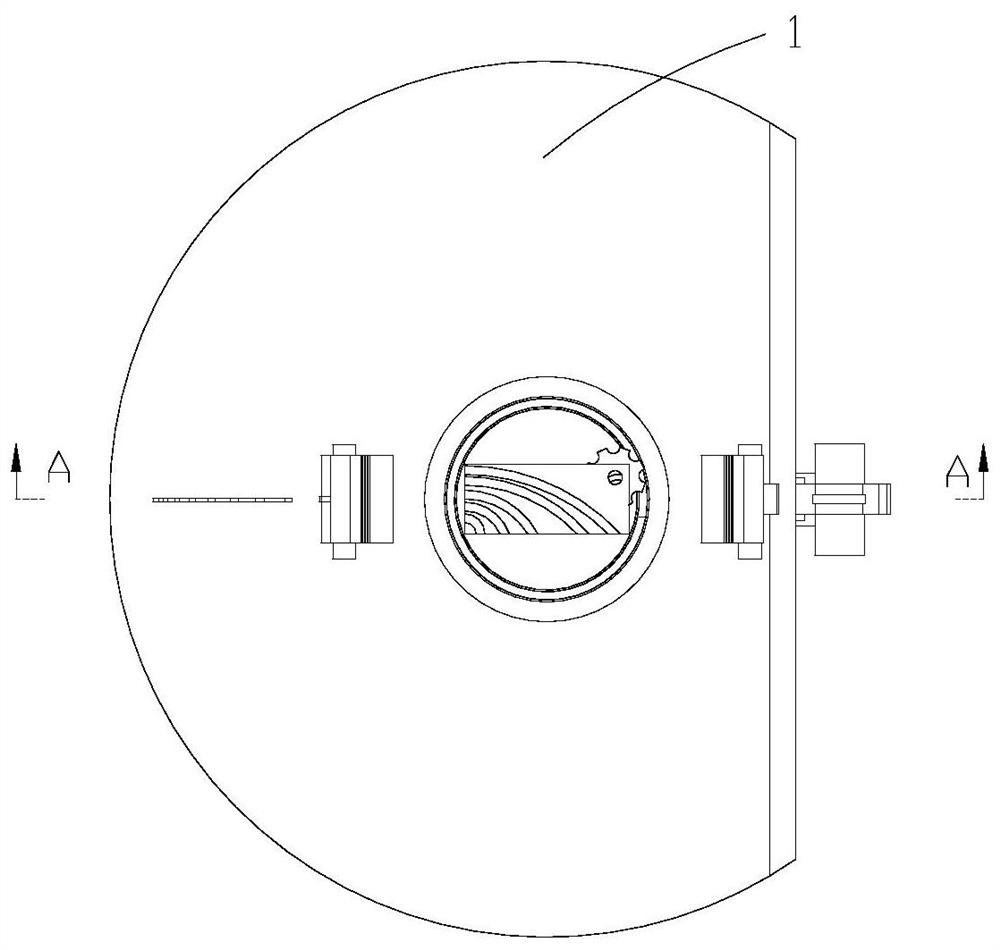

[0026] Such as Figure 1-8As shown, a kind of iron handicraft production equipment comprises base 1, tapered groove 11, tapered seat 12, winding part 2, first bevel gear 13, second bevel gear 14, tapered ring 15, first ball 16, The limiting part 4, the clamping part 5; the tapered groove 11 is arranged on the said base 1, the tapered seat 12 is rotatably arranged on the said tapered groove 11, and the winding part 2 is arranged on the said tapered seat 12 Above, the first bevel gear 13 is arranged on the said bevel seat 12, the second bevel gear 14 is slidably arranged on the said base 1, and the bevel ring 15 is rotatably arranged on the said bevel seat 12, The first ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com