A segmental manufacturing process of duplex stainless steel mediastinal cabin

A technology of duplex stainless steel and manufacturing process, which is applied in ships and other directions, can solve the problems of increasing segmental construction cycle, affecting construction efficiency, and long segment assembly time, so as to shorten the fetal position cycle, reduce the number of times of turning over, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention is further described below in conjunction with specific embodiments:

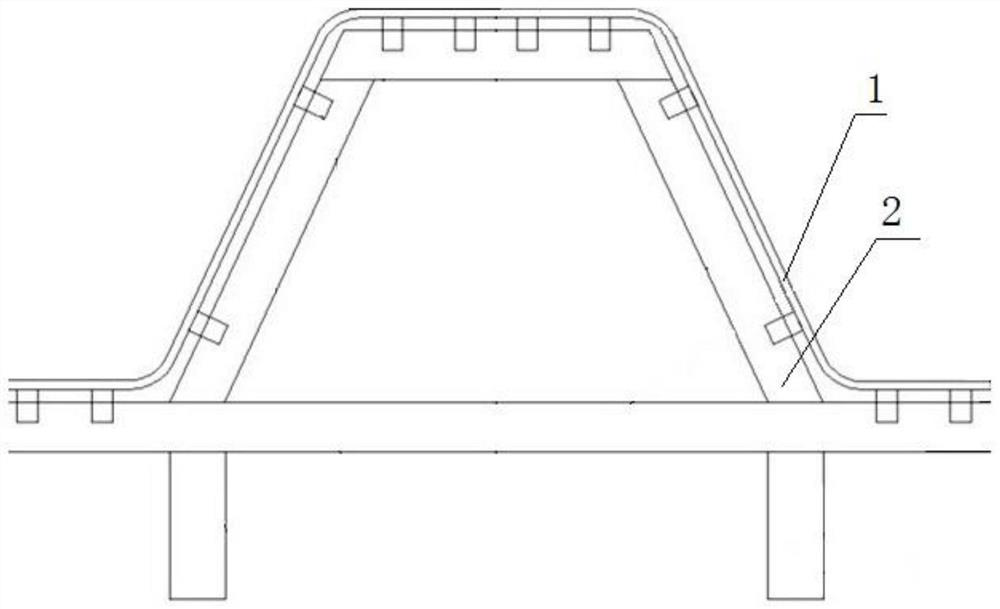

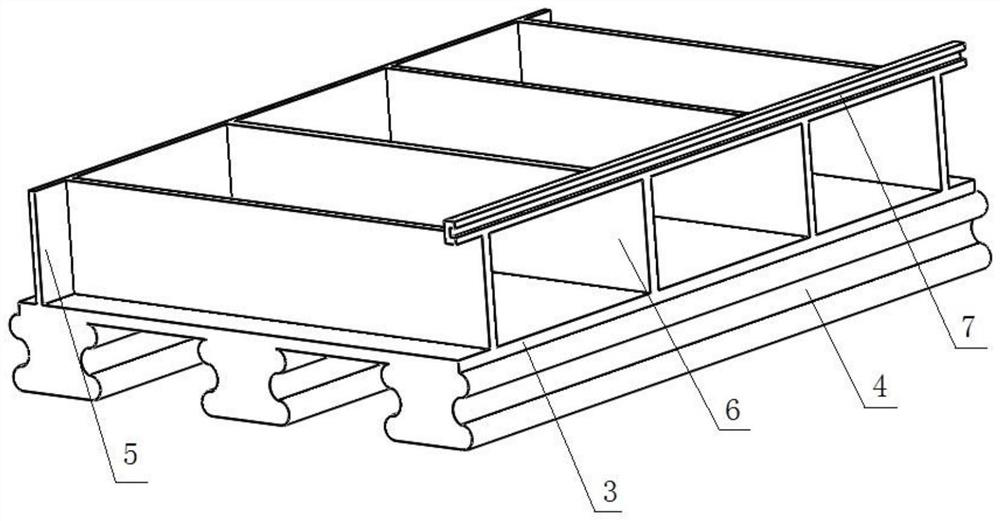

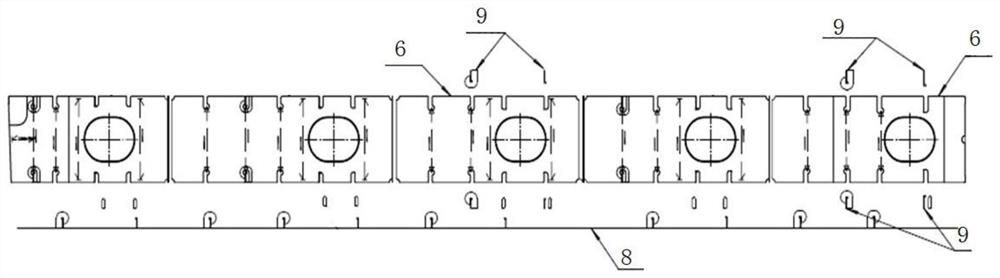

[0033] A duplex stainless steel mediastinal compartment manufacturing process, such as Figure 1-4 As shown, the duplex stainless steel medial compartment is divided into the first longitudinal wall segment and the second longitudinal wall segment to be constructed separately. After the first longitudinal wall segment is completed, the second longitudinal wall segment is constructed. The two construction methods are the same. The completed first vertical wall segment is turned over 180° and mounted on the second vertical wall segment, and then the first vertical wall segment and the second vertical wall segment are turned over 180° as a whole, and the first vertical wall segment is turned over 180° After loading and closing on the second longitudinal wall segment, evenly arrange some weights on the first longitudinal wall segment to reduce welding defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com