Range hood packaging device and packaging method thereof

A range hood and packaging technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of inability to solve oil fume pollution, low efficiency of manual packaging, high labor intensity, etc., to save the time required for packaging, and to achieve a coherent overall operation. With reliable, good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

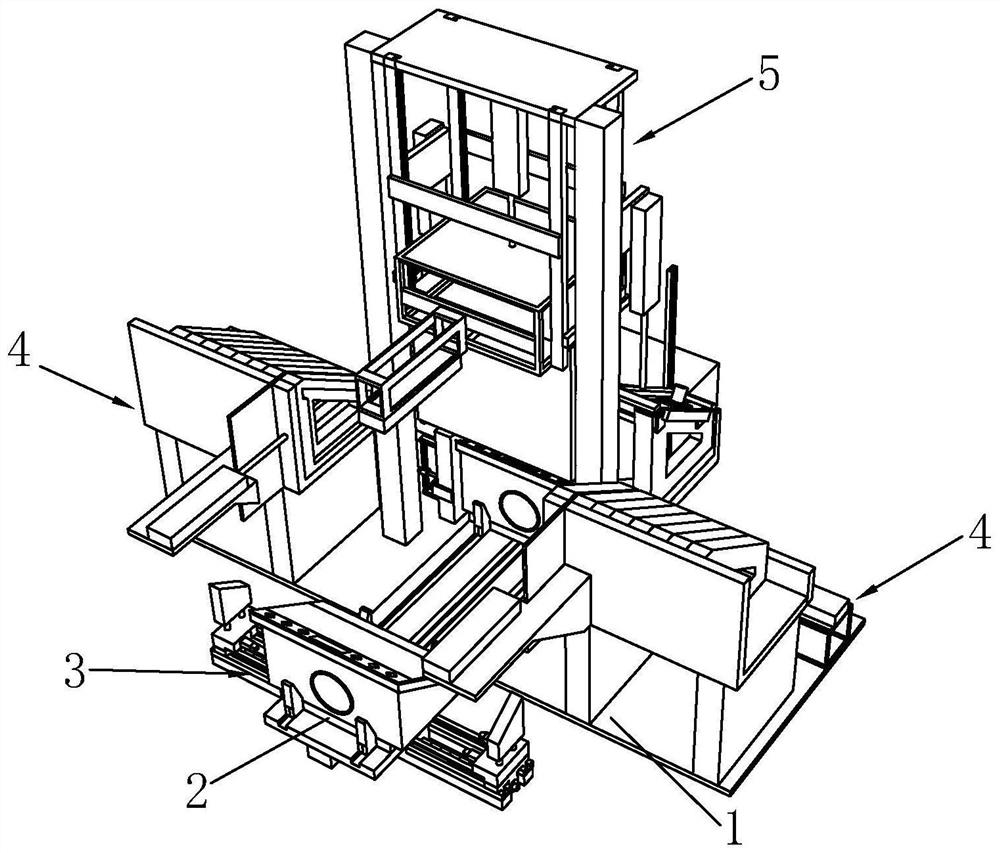

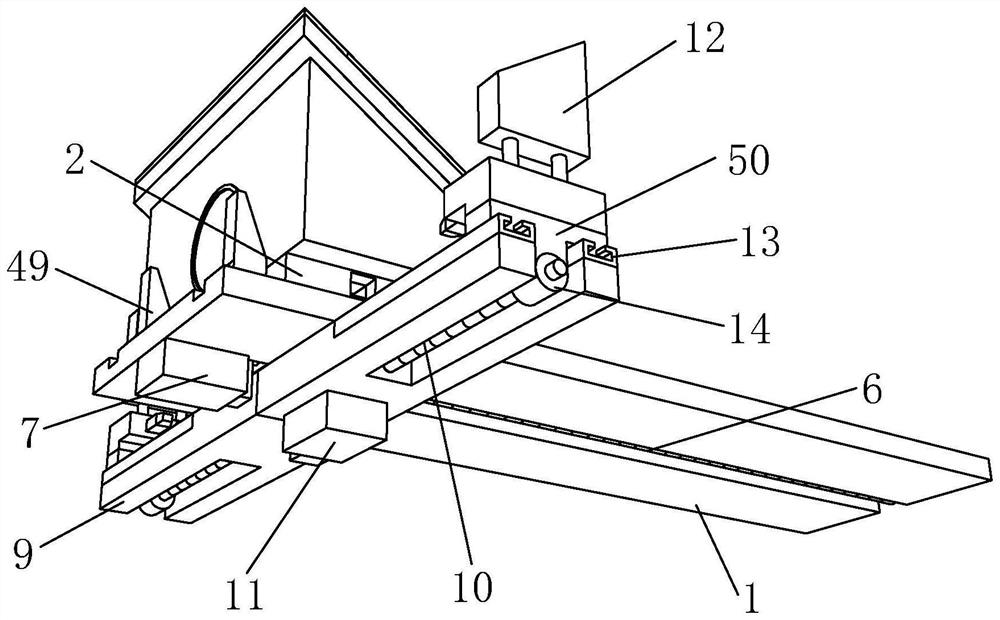

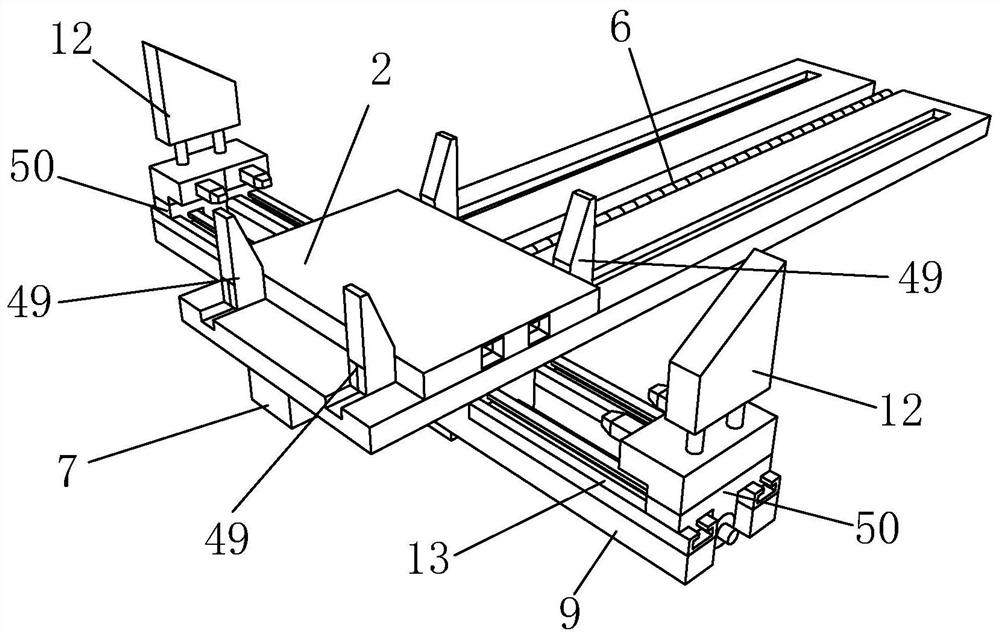

[0040] Such as Figure 1 to 11 As shown, it is a hood packaging device of the present invention, including a rack 1, a slide 2, a positioning mechanism 3, a foam bracket mounting mechanism 4, and a top push packaging mechanism 5, a positioning mechanism 3, and a foam mounting mechanism and a top push packaging mechanism 5. On the rack 1, the slide 2 is provided on the frame 1, and the slide 2 is slidably connected to the frame 1, and the frame 1 is provided with a conveyance screw 6 and a transport motor 7, and the carrier rod 6 is rotated, transported. The motor 7 is connected to the transporting screw 6, the transport motor 7 drives the transporting screw 6 to rotate, the slide plate 2 is provided with a transport nut, and the transport nut is arranged on the conveyor rod 6 and connected to the screw, and the positioning mechanism 3 is used for the cigarette The positioning of the machine on the slide 2, the foam bracket mounting mechanism 4 is used in the foam bracket of the hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com