Fabrication method of high-conductivity cable

A high-conductivity, cable technology, used in conductor/cable insulation, cable/conductor manufacturing, circuits, etc., can solve problems such as unstable conductivity, limited conductivity, and inability to achieve high conductivity, and achieve guaranteed accuracy. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

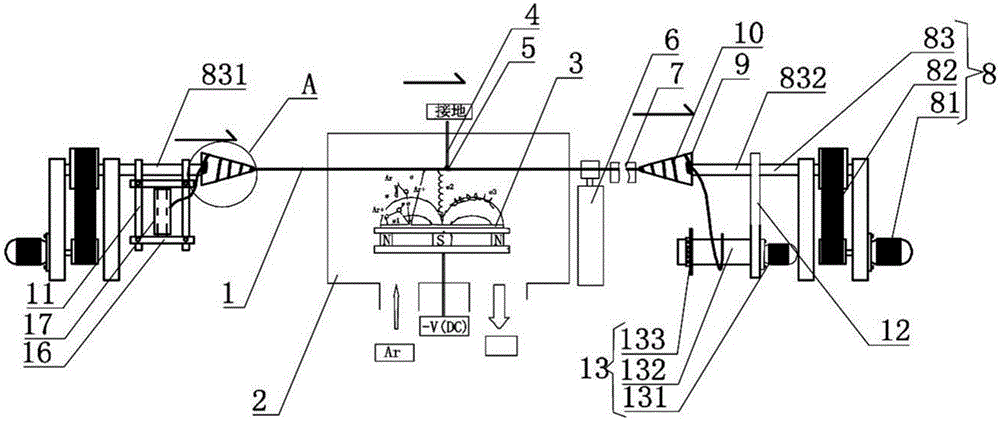

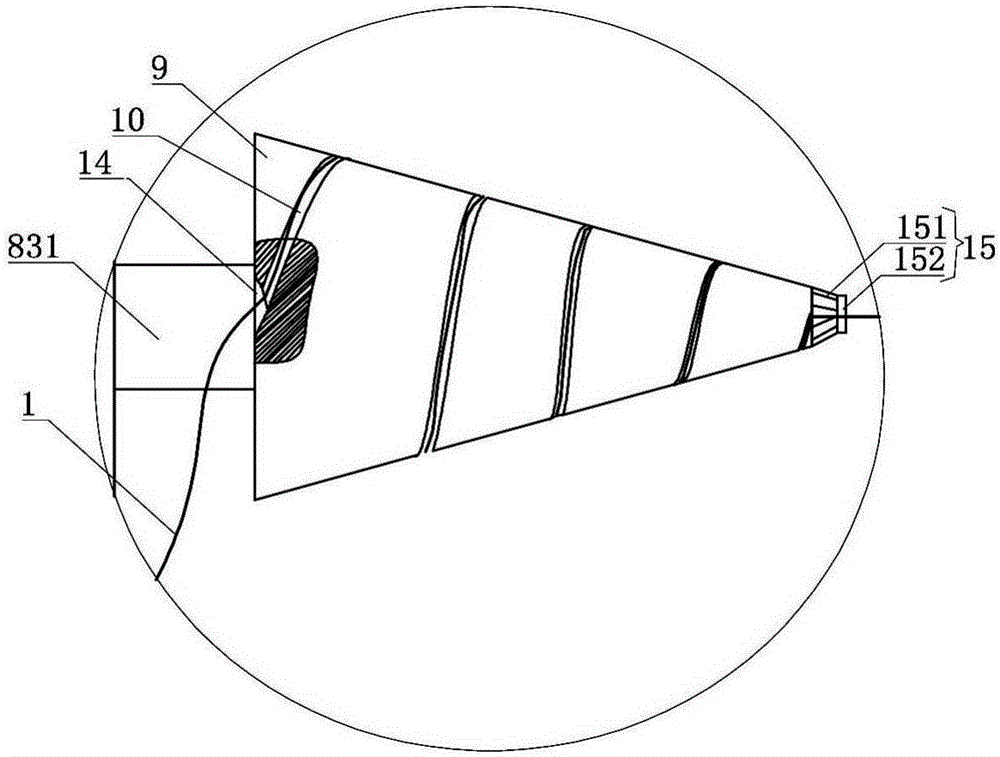

[0048] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0049] Such as figure 1 , figure 2 Shown, a kind of preparation method of high conductivity cable, described method comprises:

[0050] S1, using copper and aluminum conductors 1 as raw materials;

[0051] S2, the conductor 1 is passed through the magnetron sputtering machine 2 to form a graphene film, the conductor 1 rotates through the magnetron sputtering machine 2, and the magnetron sputtering machine 2 uses graphene as a target, The magnetron sputtering machine 2 is provided with a grounding wire, and the grounding wire is connected to the conductor 1 through a carbon brush 5;

[0052] S3, the conductor 1 forms an insulating layer outsid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com