Garbage bin loading device

A technology of garbage bins and trash cans, which is applied in the directions of garbage receptacles, transportation and packaging, waste collection and transfer, etc. It can solve the problems of unstable holding of the buckets, and achieve the effects of correct posture, improved feeding efficiency, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

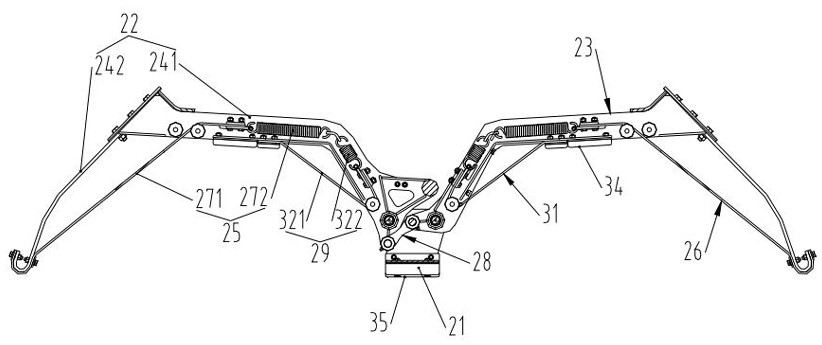

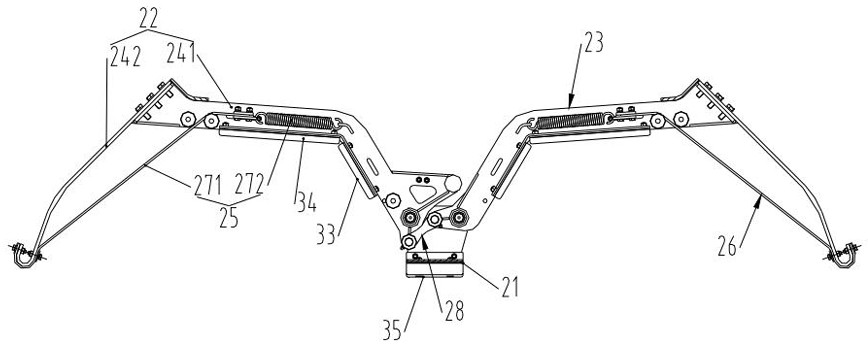

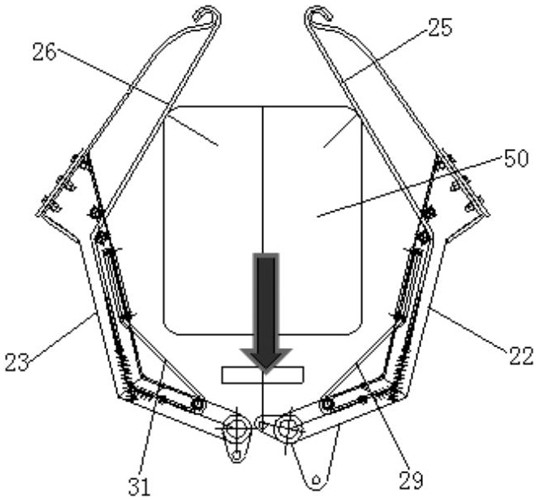

[0034] refer to figure 1 and figure 2 , the preferred embodiment of the present invention provides a garbage bin loading device, including a bucket holding mechanism 20 for loading garbage cans 50, the bucket holding mechanism 20 includes: a mounting base 21, used for cooperating with picking up garbage The first holding arm 22 and the second holding arm 23 of the bucket 50 , the first elastic bar group 25 and the second elastic bar group 26 elastically stretched along the length direction of the bucket 50 , and the bucket holding driving member 28 . The first arm 22 and the second arm 23 are arranged at a distance from each other, and the fixed ends of the first arm 22 and the second arm 23 are respectively hinged to the installation base 21 . The first elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com