A fully automatic bottle unscrambler for production and processing of anti-mosquito spray

A fully automatic, bottle unscrambler technology, applied in the direction of conveyor objects, loading/unloading, and resistance to vector-borne diseases, etc., can solve problems such as large manpower consumption, bottles stacked together, and blocked outlets, so as to protect the safety of bottles , reduce speed and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

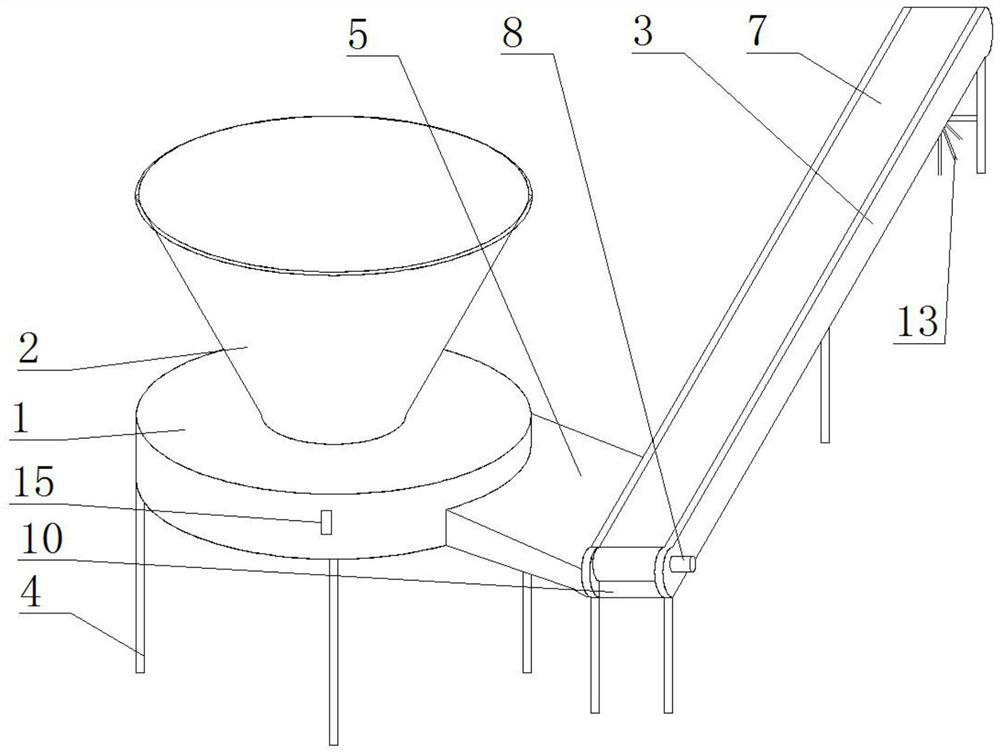

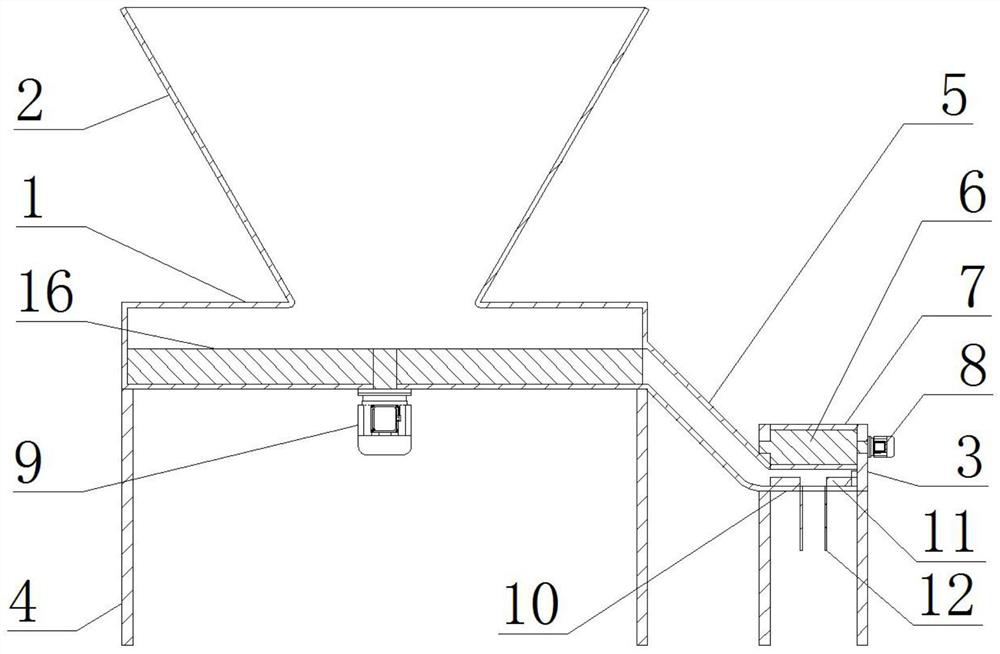

[0030] As a preferred embodiment of the present invention, the bottom of one side of the sliding sleeve 5 is welded to the bottom of the sleeve 1 , and the bottom of the other side of the sliding sleeve 5 is welded to one side of the slide plate 10 .

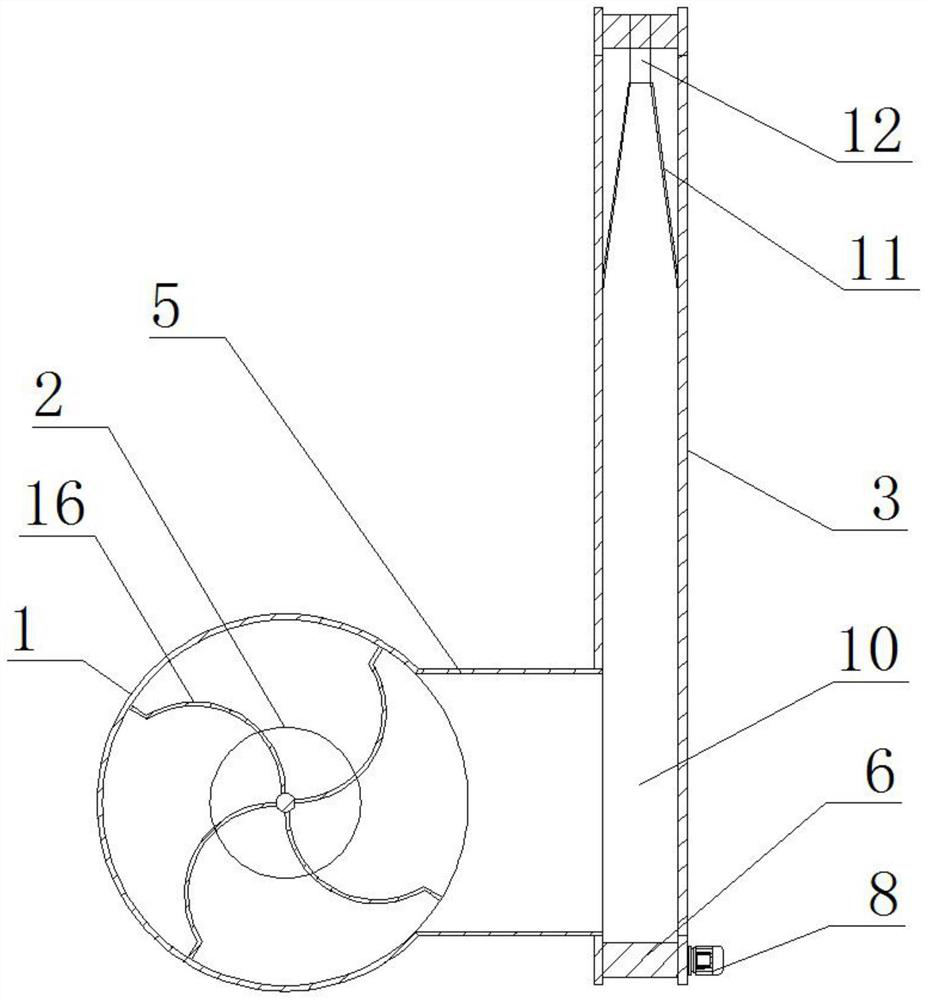

[0031] As a preferred embodiment of the present invention, the height of the scraper 16 is less than the height of the sleeve 1, the outer end of the scraper 16 is clamped on the inner wall of the sleeve 1, and the scraper 16 is used to continuously push the bottle to the inner wall of the sleeve 1. The outer side of the sleeve 1 is pushed, and the bottle is gradually dispersed due to the wider range of the outer side, until the bottle moves out from one side of the sleeve, and slides down through the sliding sleeve 5, using the inertia of the bottle, the bottle is stuck into the sliding plate Between 10 and belt 7.

[0032] As a preferred embodiment of the present invention, the rotating rod 13 includes a support rod and a main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com