Assembled modular water permeable brick and preparation method thereof

A modular, permeable brick technology, used in ceramic products, other household appliances, paving surfaces paved with prefabricated blocks, etc., can solve the problems of high strength requirements and paving requirements, harmful gases, prolonged working hours, etc., to achieve durable performance. Good, wide application range, the effect of solving large dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

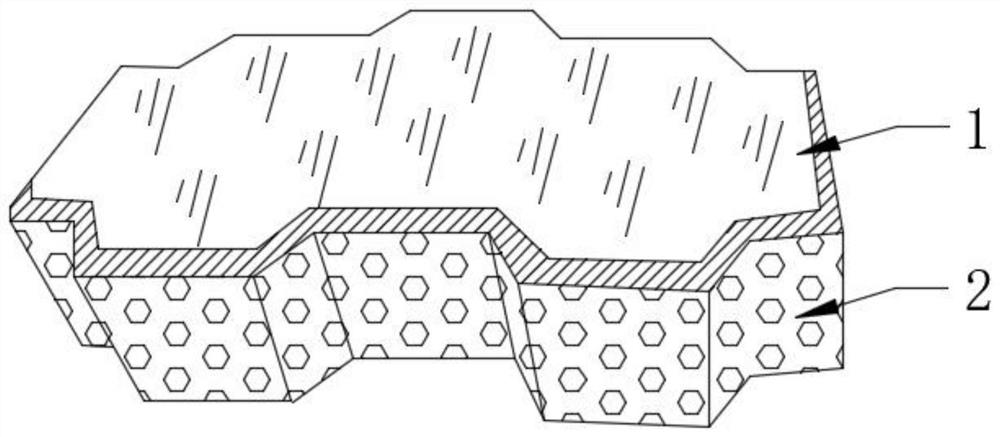

[0030] see figure 1 , the present invention provides a technical solution: an assembled modular permeable brick, including a permeable base 2 and a surface layer 1, located on the permeable base 2, the permeable base 2 is steel slag permeable concrete with a porous network structure, and the surface layer 1 It is a water-permeable glue-sand polymer, and the thickness of the surface layer 1 is 8-10mm.

[0031] The permeable base layer 2 comprises raw materials of the following weights:

[0032] 900-1200kg of steel slag with a particle size of 3-5mm, 600-800kg of steel slag with a particle size of 5-10mm, 350-400kg of po42.5 low-alkali cement, 1.5-3kg of high-efficiency water reducer, and 130-150kg of magnetized water.

[0033] Topping 1 includes the following weights of ingredients:

[0034] 270-300kg of 20-40 mesh machine-made sand, 70-100kg of cementitious material, 3-5kg of polymer sol, and 24-30kg of magnetized water.

[0035] Among them, it also includes a preparation m...

Embodiment 2

[0042] The invention provides a technical solution: an assembled modular permeable brick, including a permeable base 2 and a surface layer 1, located on the permeable base 2, the permeable base 2 is steel slag permeable concrete with a porous network structure, and the surface 1 is Water-permeable glue sand polymer, the thickness of the surface layer 1 is 9mm, and the thickness of the water-permeable base layer 2 is determined according to the soil base and bearing weight.

[0043] The permeable base layer 2 comprises raw materials of the following weights:

[0044] 1000kg of steel slag with a particle size of 3-5mm, 700kg of steel slag with a particle size of 5-10mm, 375kg of po42.5 low-alkali cement, 2.2kg of high-efficiency water reducing agent, and 140kg of magnetized water.

[0045] Topping 1 includes the following weights of ingredients:

[0046] 285kg of 20-40 mesh machine-made sand, 85kg of cementitious material, 4kg of polymer sol, and 27kg of magnetized water.

[0...

Embodiment 3

[0054] The invention provides a technical solution: an assembled modular permeable brick, including a permeable base 2 and a surface layer 1, located on the permeable base 2, the permeable base 2 is steel slag permeable concrete with a porous network structure, and the surface 1 is Water-permeable glue-sand polymer, the thickness of the surface layer 1 is 10mm, and the thickness of the water-permeable base layer 2 is determined according to the soil base and bearing weight.

[0055] The permeable base layer 2 comprises raw materials of the following weights:

[0056] 1200kg of steel slag with a particle size of 3-5mm, 800kg of steel slag with a particle size of 5-10mm, 400kg of po42.5 low-alkali cement, 3kg of high-efficiency water reducing agent, and 150kg of magnetized water.

[0057] Topping 1 includes the following weights of ingredients:

[0058] 20-40 mesh machine-made sand 300kg, cementitious material 100kg, polymer sol 5kg, magnetized water 30kg.

[0059] Among them,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap