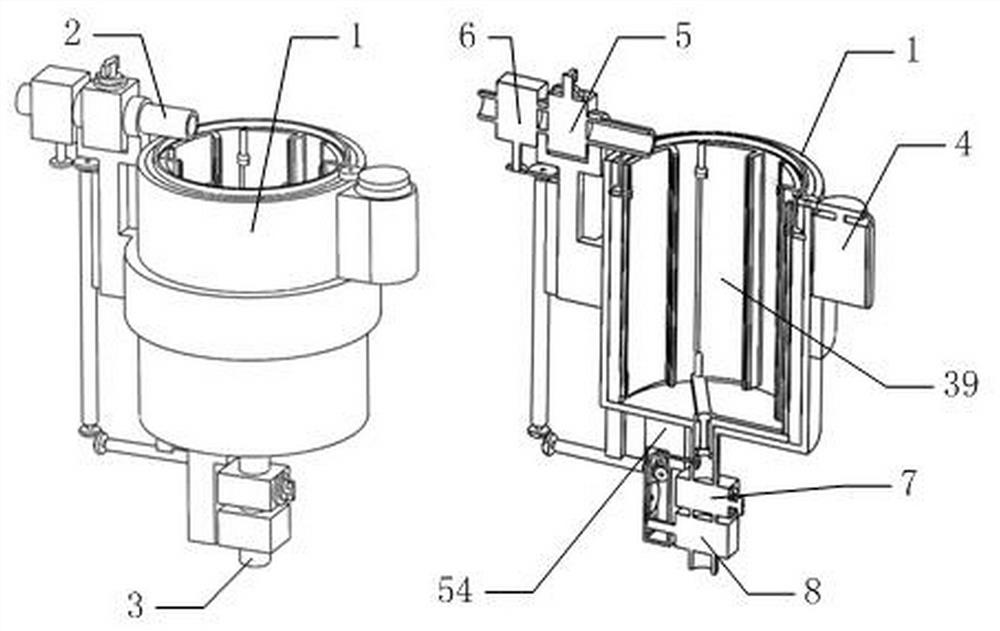

Electrochemical electrolysis equipment capable of degrading COD and application thereof in field of sewage

An electrolysis equipment and electrochemical technology, applied in the field of electrolysis, can solve the problems of troublesome replacement, affecting the adhesion of the coating layer, inconsistent product quality, etc., and achieve the effect of simple use and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

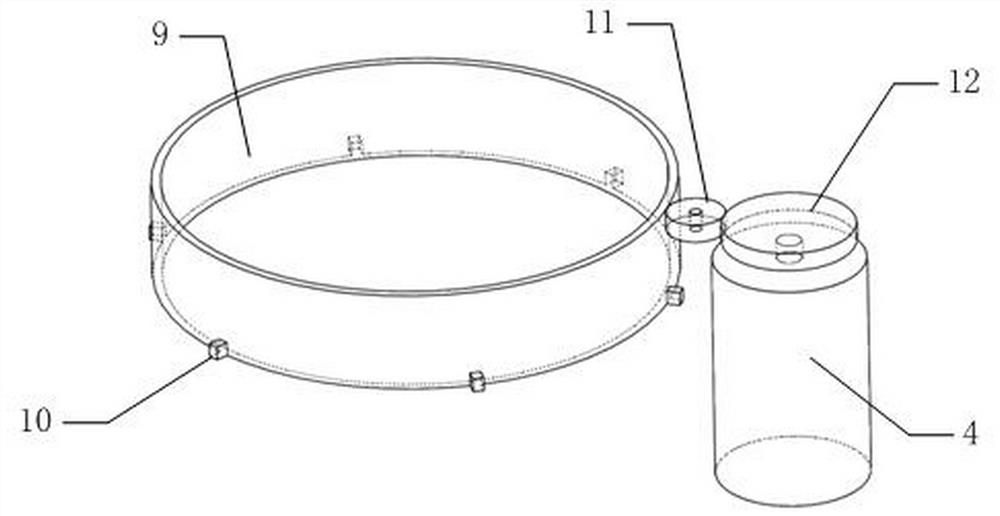

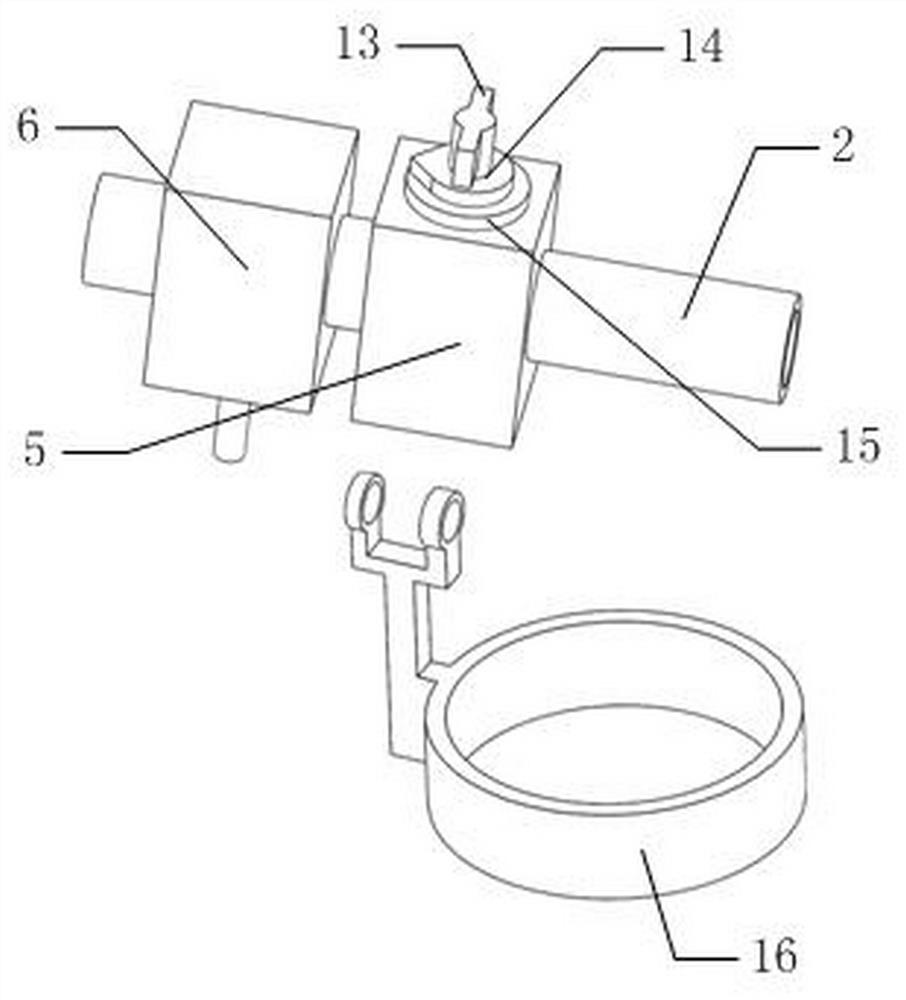

[0064] Embodiment 1, because there is a certain frictional resistance between the electrolytic cell 1 and the rotating cylinder 39, the rotation of the ring gear 9 will drive all the eighteenth gears 41 to rotate, and the rotation of the eighteenth gear 41 will drive all the third shafts 44 rotation, the rotation of the third rotating shaft 44 drives all the rotating plates 40 to swing relative to the rotating cylinder 39; on the other hand, the rotation of the ring gear 9 will drive the toggle block installed on it to rotate, so that the toggle block is in the corresponding toggle groove 50 Sliding inside; after the toggle block slides from one side of the corresponding toggle groove 50 to the other side and contacts the side surface on the other side of the toggle groove 50, the rotating plate 40 is driven to rotate at an angle of 90 degrees, and the ring gear 9 Rotation will drive the rotating cylinder 39 to rotate by the toggle block.

Embodiment 2

[0065] Embodiment 2, because in the initial state, one end of the limit block is located in the slot 47, the rotation of the rotating cylinder 39 relative to the electrolytic cell 1 is limited, and it is ensured that the ring gear 9 will first drive the eighteenth gear when it starts to rotate. 41 rotates and drives the toggle block to slide in the toggle groove 50; after the third rotating shaft 44 drives the rotating plate 40 to swing 90 degrees, the third rotating shaft 44 also drives the cam 43 to rotate 90 degrees at the same time, so that the groove on the cam 43 Cooperate with the limit rod 42, in this state, the limit rod 42 will slide towards the side of the cam 43 under the pulling force of the spring 45, and the limit rod 42 will disengage from the card slot 47, releasing the restriction on the rotating cylinder 39 , so that the ring gear 9 drives the rotating cylinder 39 to rotate through the toggle block.

[0066] Under the above two embodiments, the rotating cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com