High-rise building shear wall cylinder outwards-extending wall cap building structure system

A technology for high-rise buildings and building structures, applied in building components, special structures, building structures, etc., and can solve problems such as stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

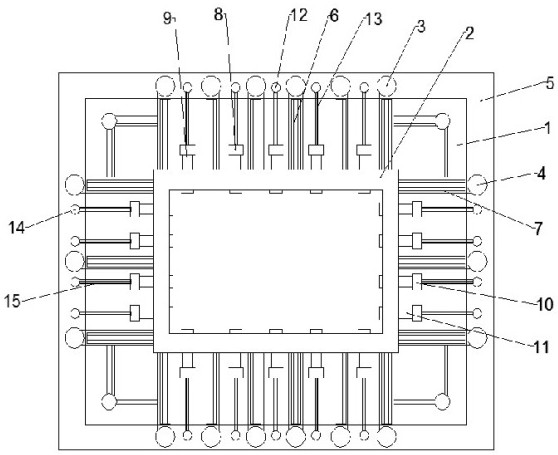

Embodiment 1

[0026] Such as Figure 1-4 As shown, the high-rise building shear wall cylinder outer extension wall cap building structure system according to the embodiment of the present invention includes a foundation pile platform 1, a shear wall cylinder 2, a fixed frame column one 3 and a fixed frame column two 4, the The shear wall cylinder body 2 and the fixed frame column one 3 and the fixed frame column two 4 are all located on the upper end of the foundation pile platform 1, and the foundation pile platform 1 is located outside the shear wall cylinder body 2 The circle is provided with a frame-shaped frame beam 5, and the two ends of the frame-shaped frame beam 5 are provided with the fixed frame column-3, and the fixed frame column-3 and the shear wall cylinder body 2 are evenly spaced. A connecting frame beam 1 6 is provided, the fixed frame column 2 4 is arranged on both sides of the frame-shaped frame beam 5, and the fixed frame column 2 4 and the shear wall cylinder 2 are pro...

Embodiment 2

[0029] Such as Figure 1-4 As shown, the pile platform 1, the shear wall cylinder 2, the fixed frame column 1 3 and the fixed frame column 2 4 are all poured with steel bars and concrete to form a concrete steel bar structure. The first fixed frame column 3 , the second fixed frame column 4 , the first support frame column 12 and the second support frame column 14 and the foundation piles are all vertical concrete reinforcement columns. The first connecting frame beam 6, the second connecting frame beam 7, the first receiving frame beam 9, the second receiving frame beam 11, the first connecting secondary beam 13 and the second connecting secondary beam 15 are all horizontal Erected bearing beams.

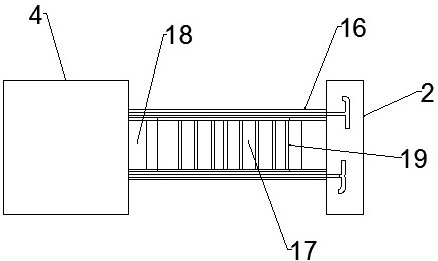

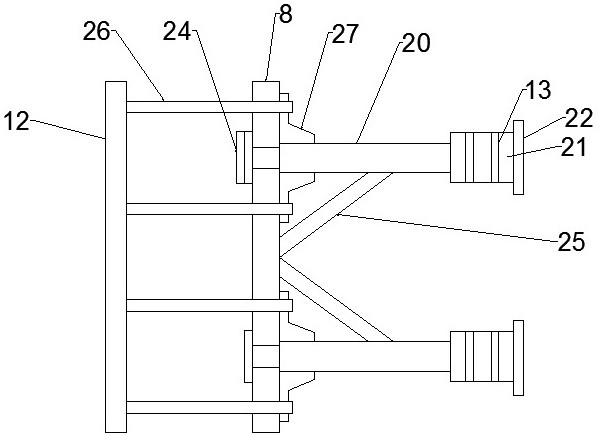

[0030] Such as Figure 1-4 As shown, the connecting frame beam 1 6 and the connecting frame beam 2 7 include frame beam gluten between the fixed frame column 1 3, the fixed frame column 2 4 and the shear wall cylinder 2 16. The middle part of the frame beam gluten 16 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com