Veneer connecting mechanism and installing method

A connection mechanism and decorative panel technology, which is applied in the field of connection of laminated ceiling decorative panels, can solve the problems of increasing the complexity of the ceiling process, and achieve the effects of improving aesthetics, reducing vibration, and small fixing points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

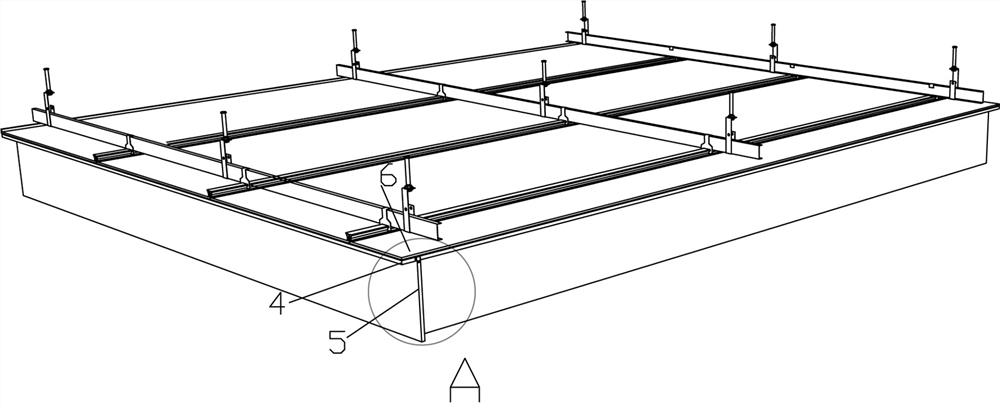

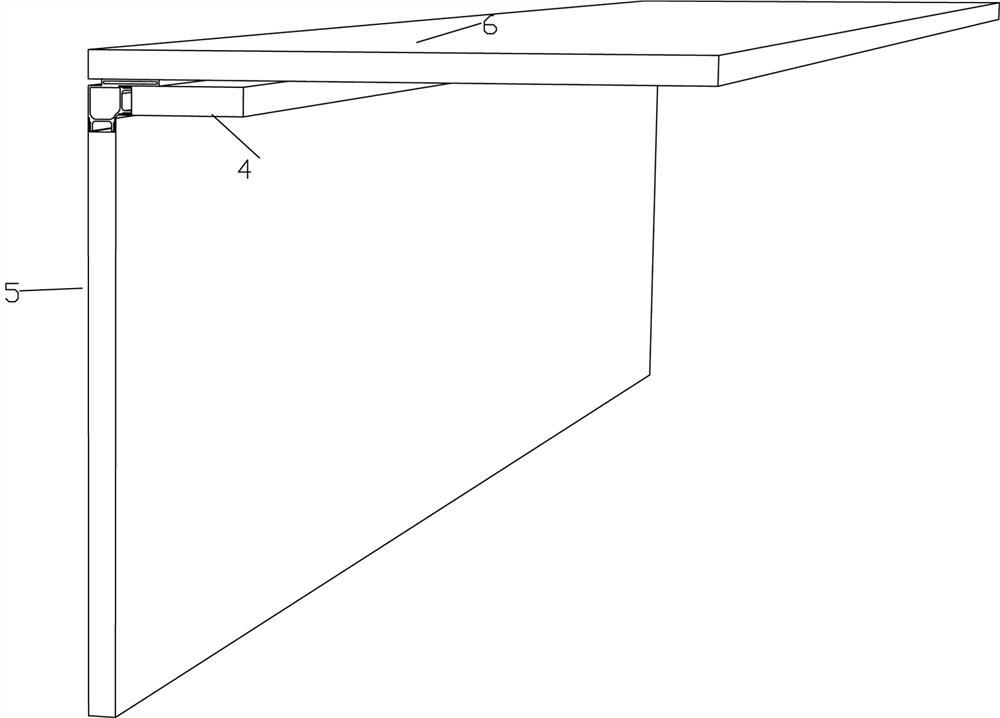

[0036] Such as figure 1 As shown, a decorative panel connecting mechanism is used to form a vertical frame panel for a stacked ceiling. The decorative panel connecting mechanism is connected with a side decorative panel 4 and a vertical decorative panel 5. The four decorative panel connecting mechanisms are surrounded by the high-position plate 6 four sides, a vertical frame plate is formed below the high-level plate 6 to realize the bending part of the stacked ceiling structure, which is convenient for further installing the low-level plate of the suspended ceiling under the vertical frame plate.

[0037] Specifically, as figure 2 and 3 As shown, the decorative panel connecting mechanism includes a connecting frame body 7, a fixing part 1 located on the upper surface of the connecting frame body 7 and used for affixed connection with the high-position plate 6, and a fixing part 1 located on the side and lower sides of the connecting frame body 7 for clamping the side decora...

Embodiment 2

[0044] Embodiment 2 is a method for installing a veneer connecting mechanism, comprising the following steps:

[0045] S1: Insert the side decorative panel 4 and the vertical decorative panel 5 into the horizontal clamping part 2 and the vertical clamping part 3; specifically, insert the upper horizontal clamping plate 21 and the lower horizontal clamping plate 22 into the horizontal clamping groove 43 At this time, the upper clamping wall 41 is located in the limiting groove 13, and the lower horizontal clamping plate 22 is in interference contact with the lower clamping wall 42; the left horizontal clamping plate 31 and the right horizontal clamping plate 32 are inserted into the vertical clamping groove 53 , the left horizontal clamping plate 31 and the right horizontal clamping plate 32 are in interference contact with the left clamping wall 51 and the right clamping wall 52;

[0046] S2: Lift up the veneer connecting mechanism with the side veneer 4 and the vertical venee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com