Steel structure integrated printed concrete wallboard device

A technology that integrates printing and concrete, applied to walls, building components, building structures, etc., can solve problems such as low efficiency, cumbersome reinforcement arrangement, and large engineering volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

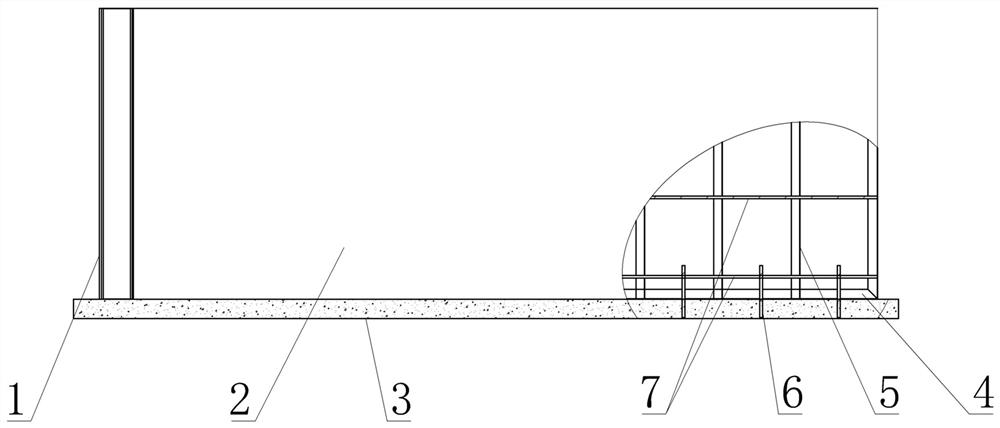

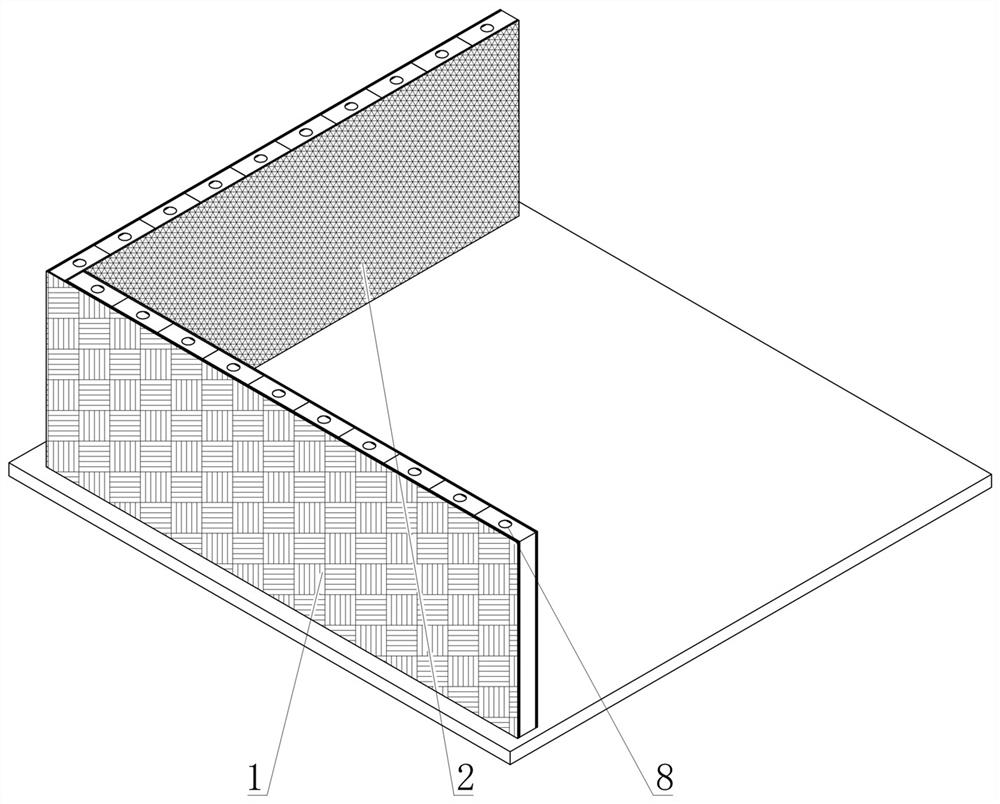

[0005] Specific implementation method: reference figure 1 , figure 2 , a steel structure integrated printed concrete wall panel device, characterized in that the outer frame of the wall panel is formed by the sky and earth keels 4, a number of vertical keels 5 are arranged longitudinally and connected with the sky and earth keels 4, and a number of horizontal steel bars 7 are connected with several vertical keels 5 and the sky and earth keels 4 Connection, detachable printing template 1 is connected with heaven and earth keel 4 to form the outside of the wall panel, and the ribbed expansion net 2 is connected with the sky and earth keel 4 to form the inner surface of the wall panel to form the main body of the wall panel; the concrete foundation 3 has built-in vertical steel bars 6, and the main body of the wall panel is inserted The vertical steel bar 6 is fixed, and the precast concrete is poured into the concrete pouring port 8 for maintenance, and the printing template 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com