Underground engineering three-way loading test device and loading test method

A loading test device and underground engineering technology, applied in measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problem of inconvenient loading and unloading test filling materials, and achieve convenient and quick addition and cleaning, avoid Roller overload, reduced traction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

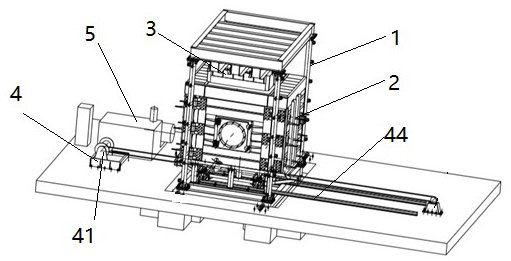

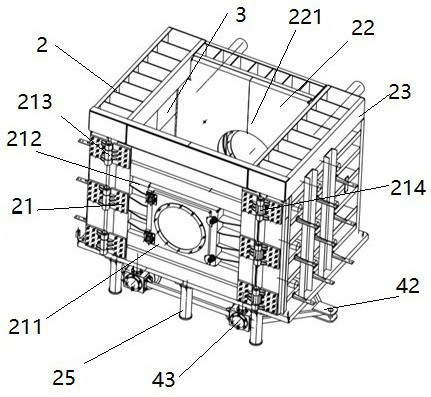

[0039] Preferred embodiment 1 of the present invention provides a kind of underground engineering three-way loading test device, with reference to Figure 1 to Figure 7 , which includes a fixed frame 1, a mobile material truck 2, a loading device 3, a traction system 4, and a hydraulic system 5, and a vertical loading device 3 is provided on the upper part of the fixed frame 1 to realize loading in the first direction from top to bottom, There is a loading device 3 on the left side of the mobile material car to realize loading in the second direction from left to right, and a loading device 3 is provided on the right side of the mobile material car to realize loading in the third direction from right to left , the second loading direction is exactly opposite to the third loading direction, perpendicular to the first vertical loading direction and on the same projected plane, the lower part of the mobile material cart 2 is provided with a traction system to realize the moving of...

Embodiment 2

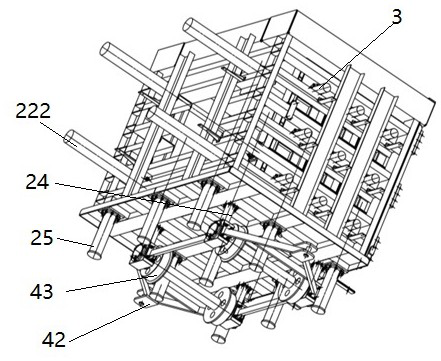

[0050] On the basis of preferred embodiment 1, such as Figure 4 As shown, further, the rear door 22 includes a rear door panel 221, a small door 211, a rear door drive cylinder 222, a rear door guide wheel 223, and a rear door guide rail 224; the rear door panel 221 is connected with the piston rod of the rear door drive cylinder 222, and the cylinder of the rear door drive cylinder 222 The seat is connected to the material trolley frame 23, the guide wheel 223 is arranged on the bottom of the rear door panel 221, the rear door panel 221 is supported on the rear door guide rail 224, the rear door guide rail 224 is installed above the bottom of the mobile material truck 2, and the rear door driving cylinder 222 drives the rear door panel 221 Realize the movement relative to the forward and backward direction of the material truck frame 23, and realize the sub-area loading test; Figure 6 Shown is a schematic diagram of the rear door 22 translation of one-third position of a ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com