Full-automatic double-sided water mill for stainless steel table knife

A stainless steel, fully automatic technology, applied in the direction of grinding frames, grinding machine parts, grinding machines, etc., can solve the problems of low work efficiency and high production cost, and achieve the effect of convenient operation, long service life and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

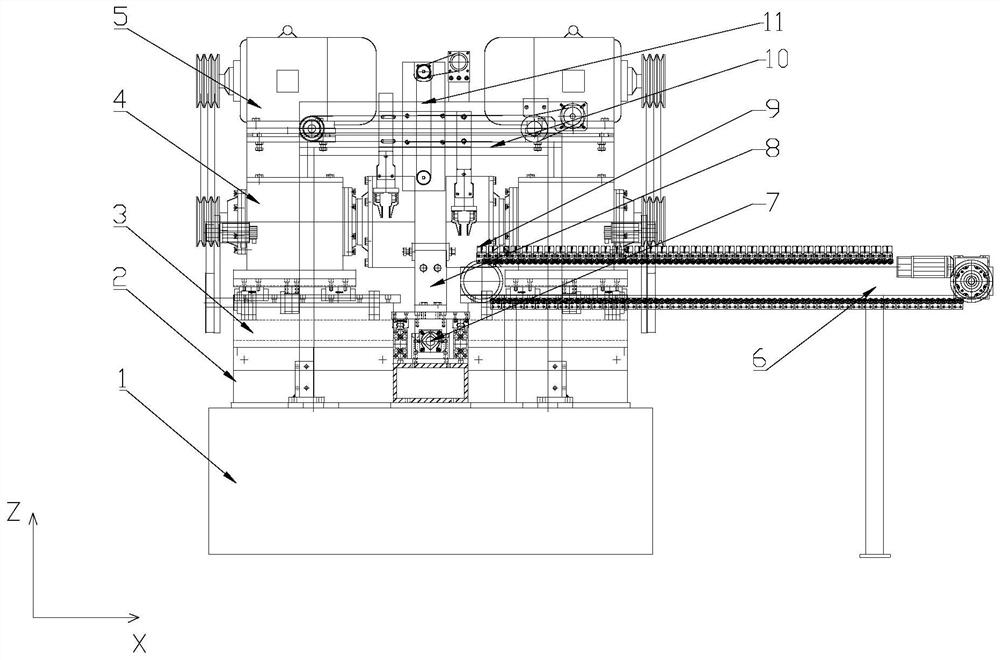

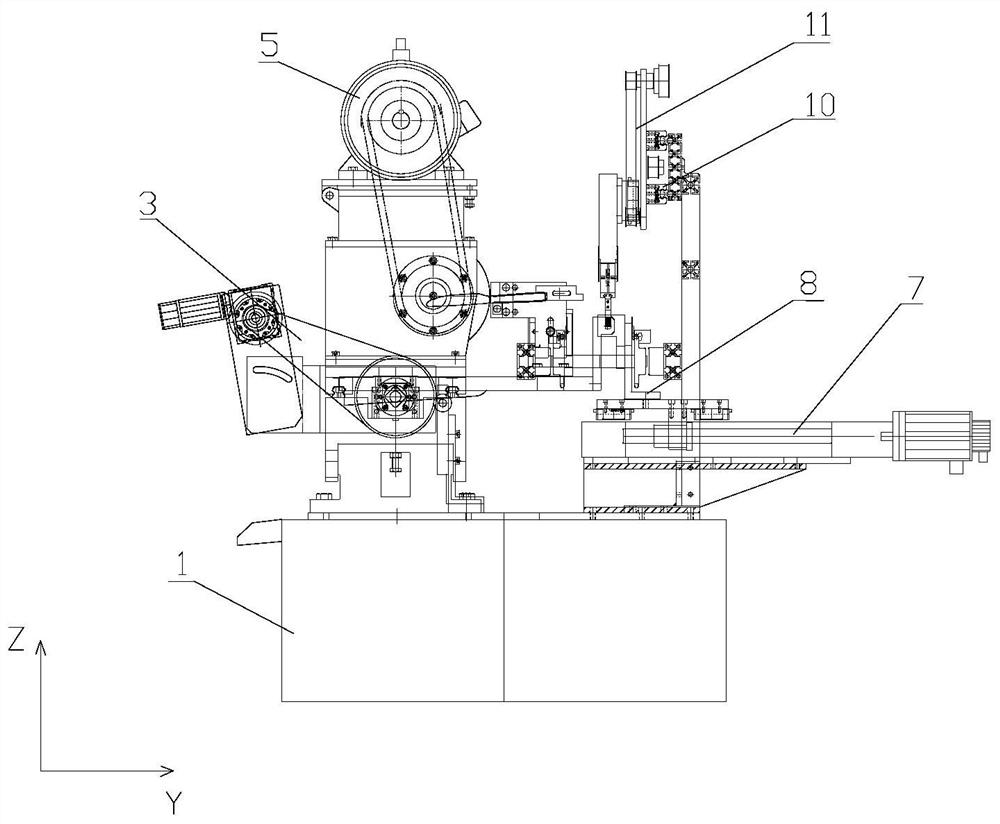

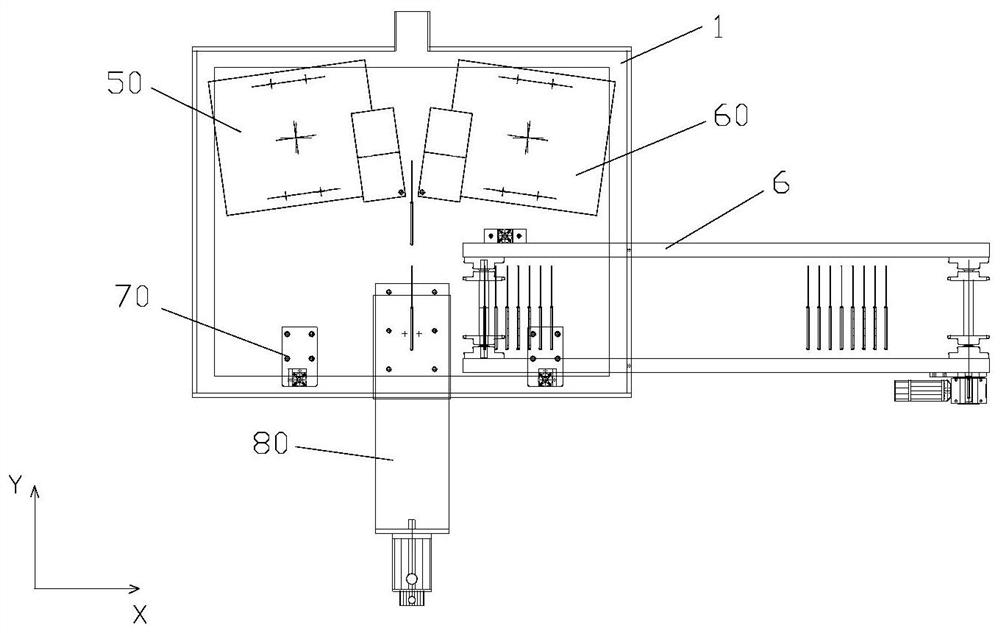

[0038] like Figure 1-3 As shown, a fully automatic double-sided water mill for stainless steel table knives provided by the present invention includes a machine base 1 and a grinding mechanism arranged on the machine base 1, a workpiece transmission mechanism 70, a knife rest feeding mechanism 80 and an automatic feeding mechanism. Platform 6; the automatic feeding table 6 is used for the automatic feeding of stainless steel table knives; the workpiece transfer mechanism 70 is used to pick up the stainless steel table knives on the automatic feeding table 6 and transport them to the knife rest feeding mechanism 80 and pick up the knife rest into The stainless steel table knife finished grinding on the feeding mechanism 80 is transported to the di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap