A discharge device that automatically adjusts the feeding speed

An automatic adjustment and discharge device technology, which is applied in the directions of transportation and packaging, loading/unloading, climate change adaptation, etc., can solve the problems of easy blockage of powder blocks and inability to adjust the discharge speed, and achieve the effect of reducing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

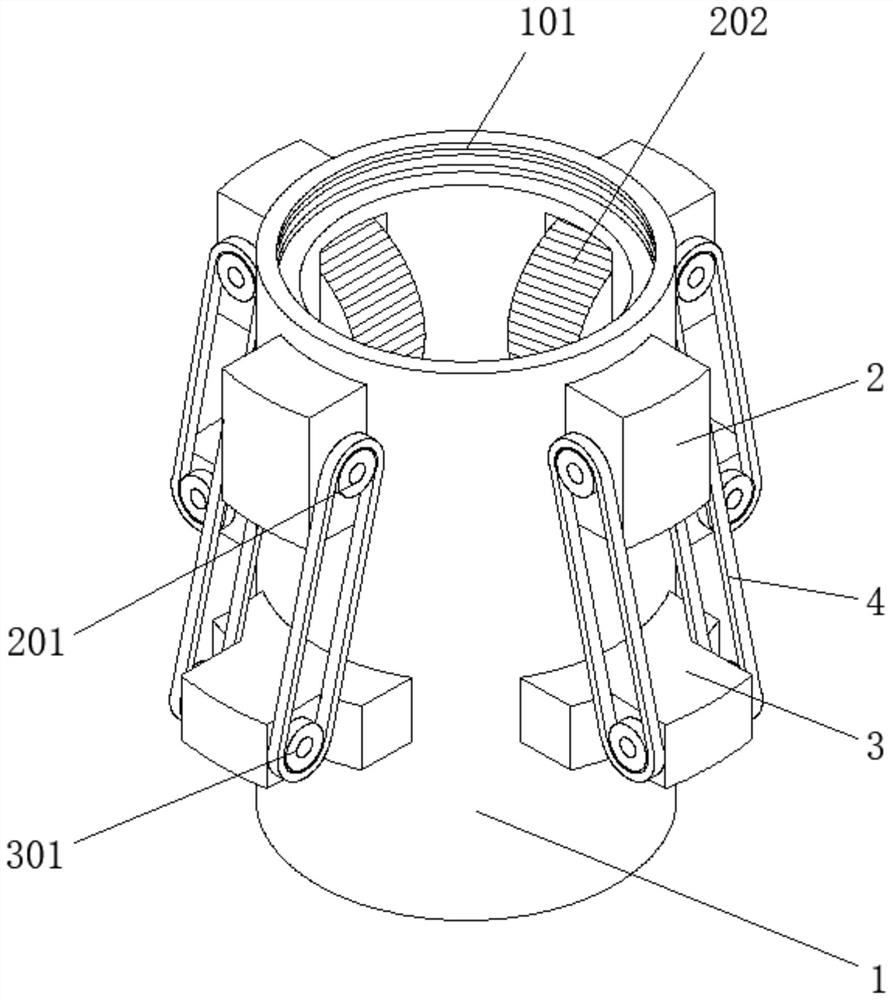

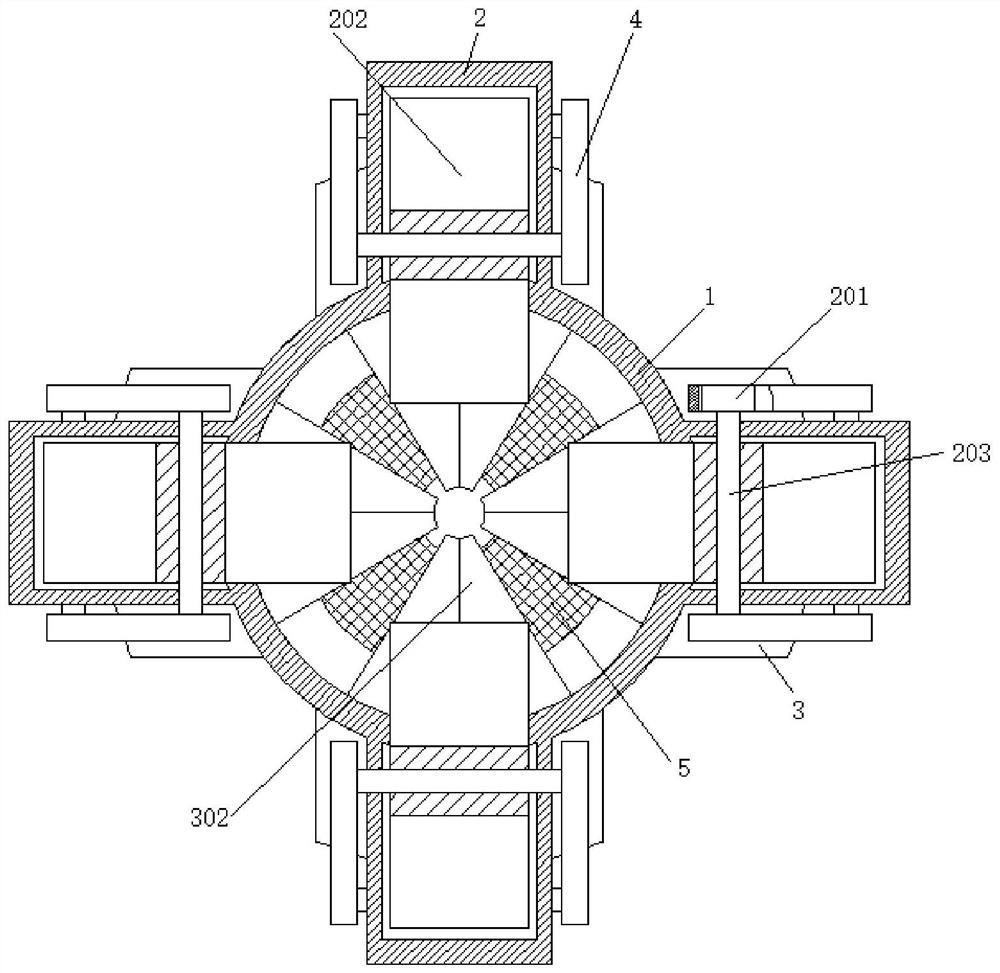

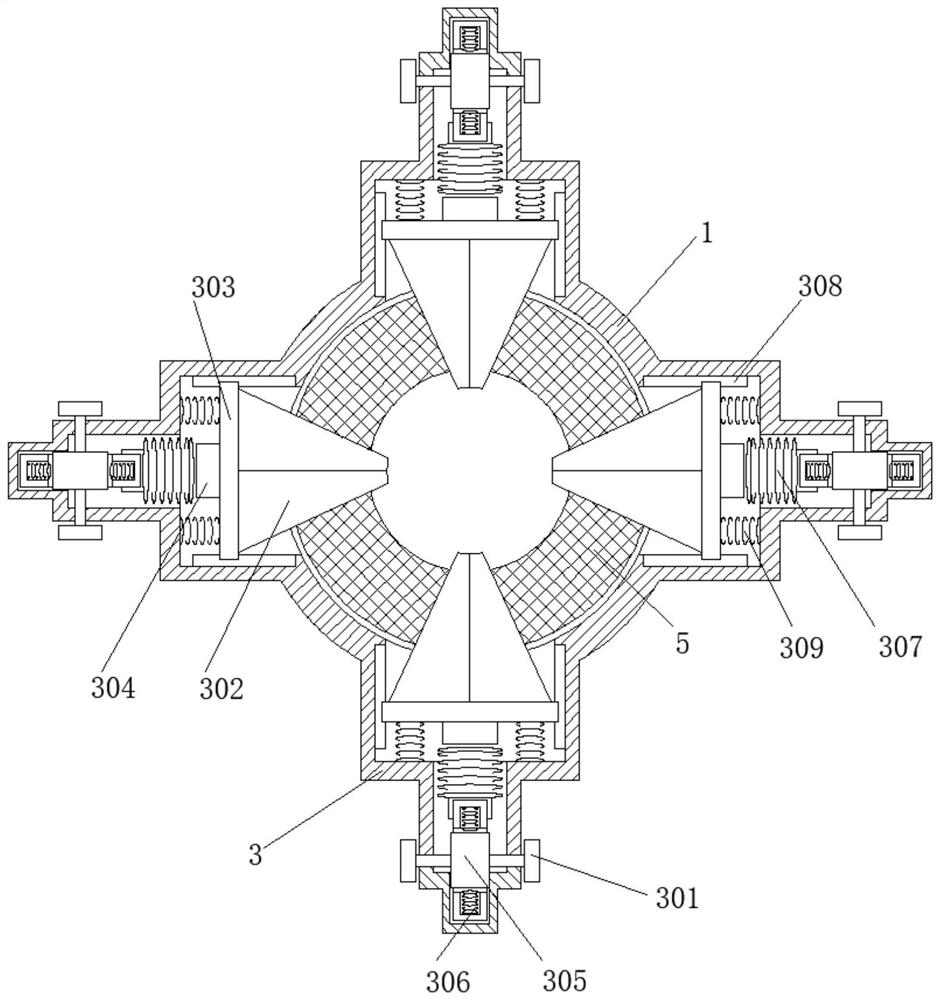

[0026] Below in conjunction with the accompanying drawings in the embodiments of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely

[0028] The inside of the transmission mechanism 2 is provided with a fan blade 202, and the fan blade 202 penetrates through the protective shell 1 and extends to the interior of the protective shell 1,

[0029] The interior of each group of current limiting mechanisms 3 is provided with a fixed casing 306, and the inner wall of the fixed casing 306 is provided with a plurality of groups of stators.

[0030] The middle position of the filter mechanism 5 is provided with a counterweight block 502, and the top of the filter mechanism 5 is provided with a plurality of groups of inclined surfaces 501.

[0033] Please refer to FIG. 3 and FIG. 7, each group of coils 312 is connected by a transmission line 313, and the output end of the transmission line 313 is connected to

[0034] Plea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com