Fluid connector and connector assembly

A connector assembly, connector technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problem of different structures of plugs and sockets, different structures, unable to meet the requirements of self-coupling connection connection, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

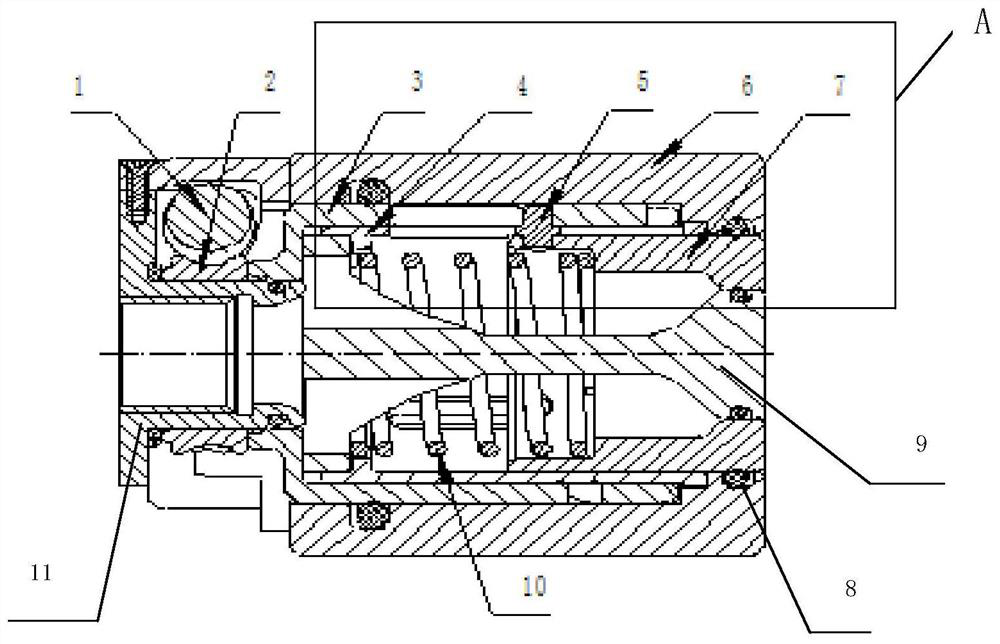

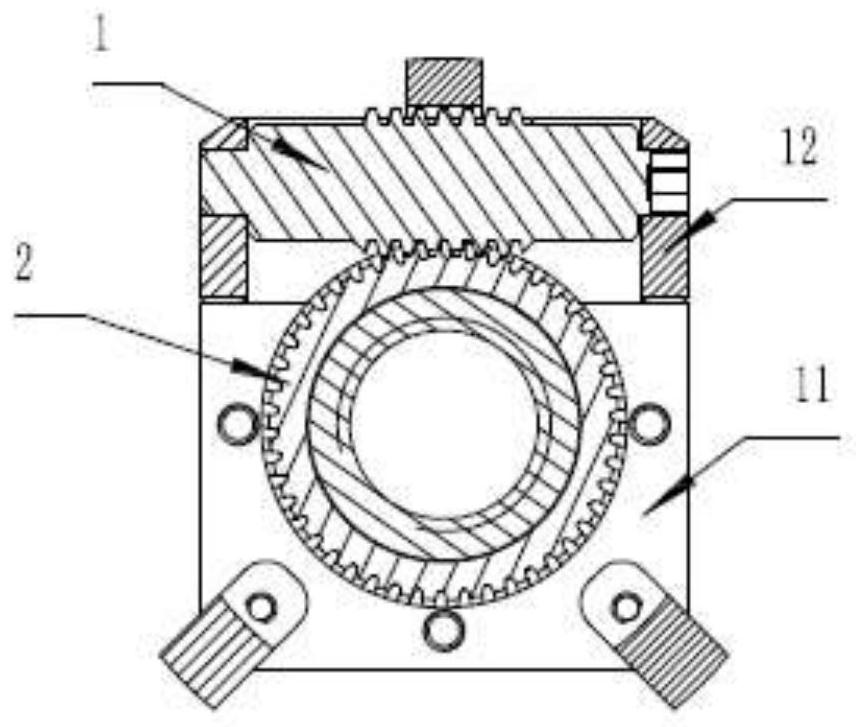

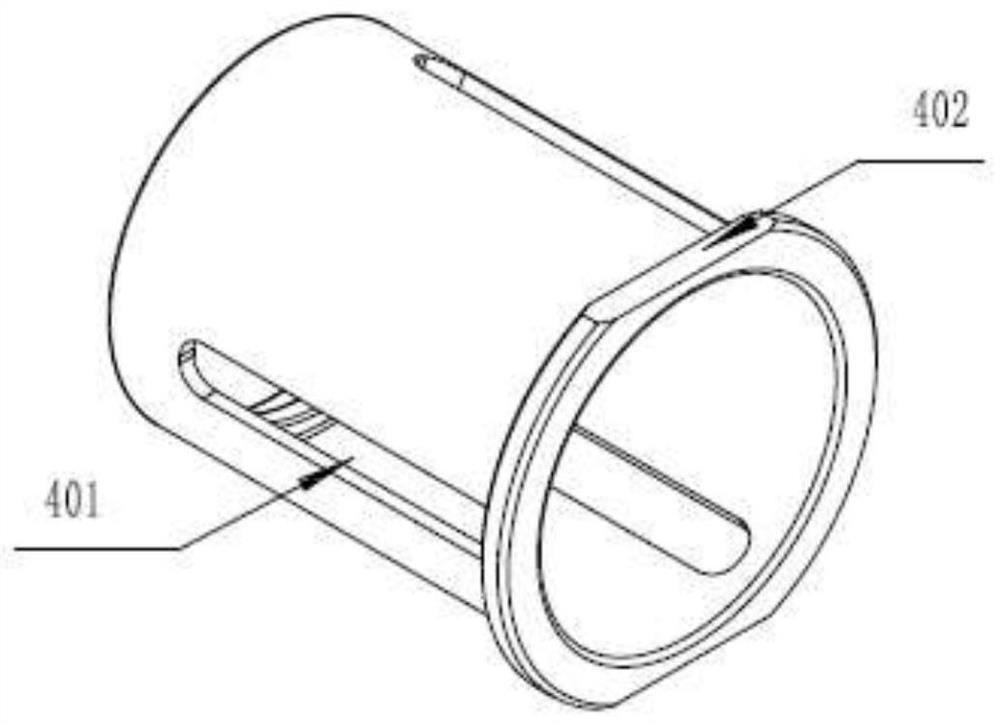

[0026] see Figure 1 to Figure 7 , a fluid connector, including a first disc housing 6 that supports the installation of the fluid connector, the inside of the first disc housing 6 has a fluid channel extending along its axial direction; the first disc housing The inner front end of the body 6 is provided with a worm 1 and a worm wheel 2 which is located at the bottom of the worm 1 and used in conjunction with it, and the outside of the worm wheel 2 is provided with a second disk casing 11 which protects it; the two sides of the top of the second disk casing 11 are respectively A baffle plate 12 supporting the worm gear and worm is provided, and the baffle plate 12 is not limited to being installed on the second disc housing 11, and may also be installed on the first disc housing 6 or an external fixture; on the baffle plate 12 Both are provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com