Flanging die for eliminating surface fluctuation of body-side sheet oil tank opening

A side wall outer plate and flanging die technology, applied in the field of stamping, can solve the problems such as the surface undulation of the side wall outer plate fuel tank port, so as to avoid the unqualified mold surface data, solve the undulation, and reduce the workload of debugging and modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046]Such asFigure 6 ,Figure 7 As shown, the lower mounting model surface adjustment block 4 is assembled on the lower model surface to install the base surface A in accordance with the mounting gap jx1 / jx2 / jx3 / jx1 / jx1 / jx2 / jx3 / jx4 and by screw 6 and pin 7.

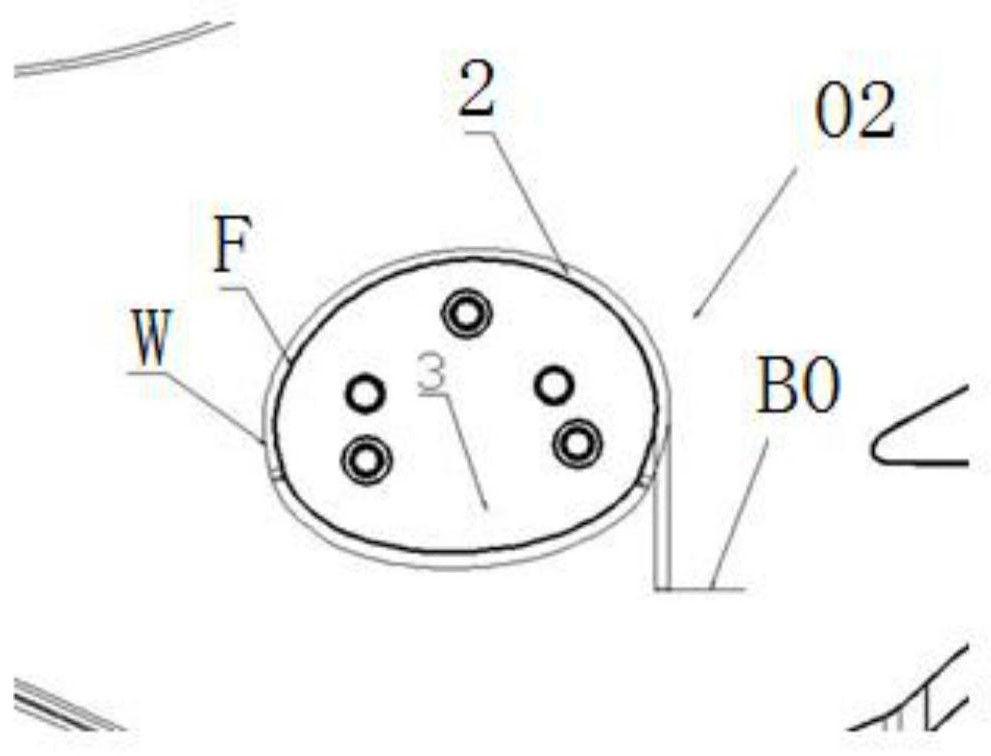

[0047]Such asFigure 8 As shown, the upper surface of the lower mold surface is the upper surface of the lower mold surface, which is the working surface T of the entire block, is an integrated surface. Work surface width B1, the lower model surface adjusts the air open distance L1 of the block surface, and the depth of the vertical space is K. The lower model surface adjusts the width B0 of the block along the horizontal direction to completely cover the lower mold width B1. The lower model surface is adjusted on the block surface, which is convenient to reduce the adjustment pad 5 to reduce the adjustment pad 5 adjustment, and avoid the air open surface higher than the lower model surface. The working surface T affe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com