Adjustable safe bush hammer

A chisel machine, adjustable technology, applied in the direction of work accessories, stone processing tools, stone processing equipment, etc., can solve the safety hazards of workers and other problems, achieve the effect of improving practicability, preventing tampering, and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

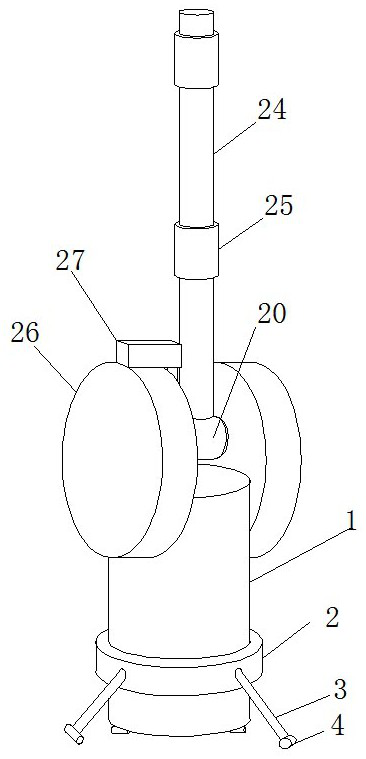

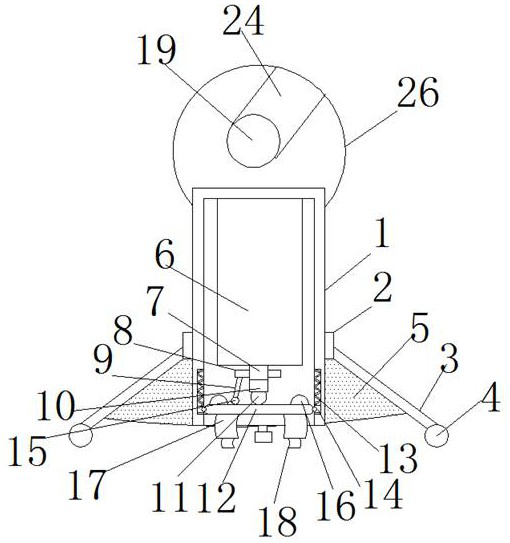

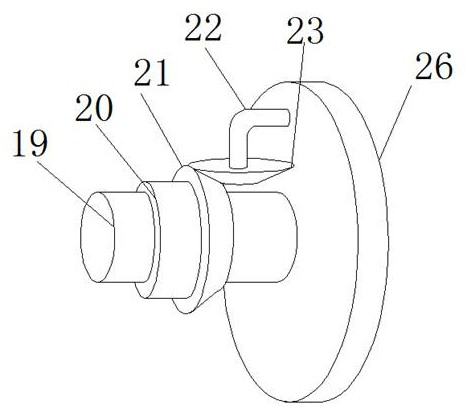

[0029] refer to Figure 1-5 , an adjustable safety chisel machine, including a power chamber 1, an air motor 6 is welded on the top inner wall of the power chamber 1, and a rotating shaft 7 is welded on the output end of the air motor 6, and a rotating shaft is welded on the outer ring of the rotating shaft 7. The connecting rod 9 is welded on one side of the bottom end of the piece 8 and the rotating piece 8, and the sliding ball 15 is welded on one end of the connecting rod 9. A rectangular groove is opened on both sides of the bottom end of the power chamber 1, and the power chamber 1 is inside the rectangular groove. A first spring 13 is provided, the bottom end of the first spring 13 is welded with a moving block 14, and one end of the moving block 14 is connected with a deflector 12 through a rotating shaft, and a semicircular protrusion 16 is welded on both sides of the top of the deflecting plate 12, and the rotating shaft The inner ring of 7 is welded with a connectio...

Embodiment 2

[0038] refer to Figure 6 , an adjustable safety chisel machine. Compared with Embodiment 1, in this embodiment, in order to improve the ability of the chisel head to chisel the wall, a cavity is opened inside the fixed column 17, and the fixed column 17 is located in the cavity. The inner wall of the top end is welded with a threaded rod 33, the threaded rod 33 is provided with a threaded bearing 34, the inner ring of the threaded bearing 34 is welded with a chisel head 18, and the chisel head 18 is slidably connected with the fixed column 17 at the cavity, When the air motor 6 drives the deflection plate 12 to deflect, the chisel head 18 begins to chisel the wall, and simultaneously due to the influence of the reaction force, the chisel head 18 drives the threaded bearing 34 to rotate on the threaded rod 33, and the threaded bearing 34 rotates upwards to When unable to rotate, the sliding ball 15 still has a pressing force on the semicircular protrusion 16, so that the chise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com