Combined mirror bracket of passenger car outside rear-view mirror

A combination technology of exterior rearview mirror, which is applied in the field of passenger car rearview mirror, can solve problems such as hindering vibration transmission, hindering vehicle body transmission, and damping pad blocking effect, so as to improve stability, improve shock resistance, and facilitate assembly The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

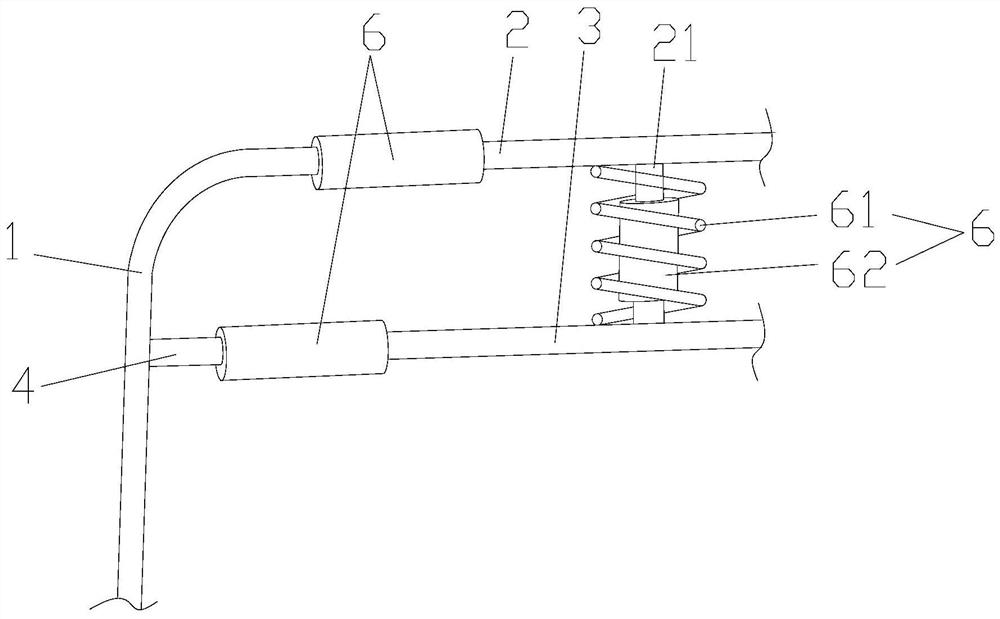

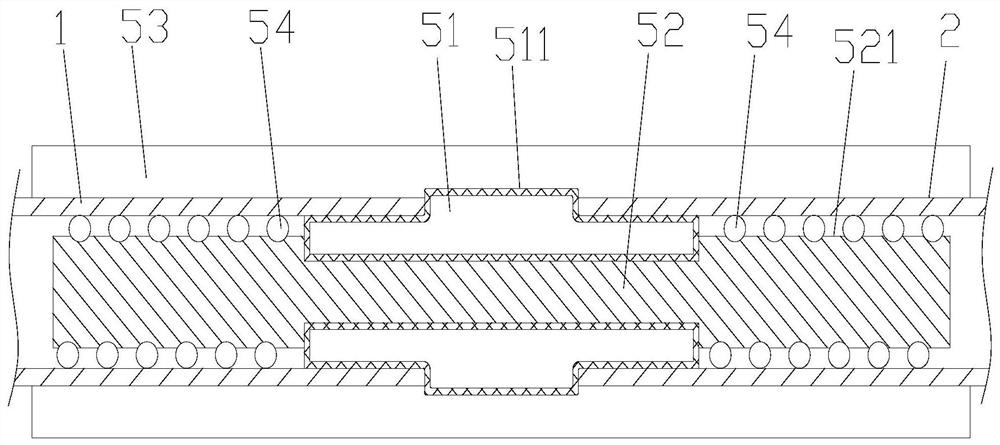

[0021] refer to figure 1 , a combined mirror frame for the exterior rearview mirror of a passenger car, comprising a mirror pole 1 connected to the rearview mirror, a main pole 2 supporting the mirror pole 1, and an auxiliary pole 3, and the mirror pole 1 is vertically arranged for fixing the exterior of the passenger car Rearview mirror, the main rod 2 and the auxiliary rod 3 are arranged horizontally, the upper end of the mirror rod 1 extends smoothly to the side of the main rod 2 to connect the main rod 2, and the upper end of the mirror rod 1 corresponds to a connecting rod connected to the auxiliary rod 3 4. The upper end of the mirror rod 1 and the end of the connecting rod 4 are provided with transverse connectors 5 connecting the main rod 2 and the auxiliary rod 3 respectively, and the rear ends of the main rod 2 and the auxiliary rod 3 are provided with mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com