Antibacterial and anti-static rotary emulsion bottle and material preparation method thereof

An anti-static and lotion bottle technology, applied in the field of lotion bottles, can solve problems such as inconvenient assembly and production, poor stability, and poor design of head cap lifting structure, etc., to achieve convenient assembly and production, feasible preparation method, and comfortable grip Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

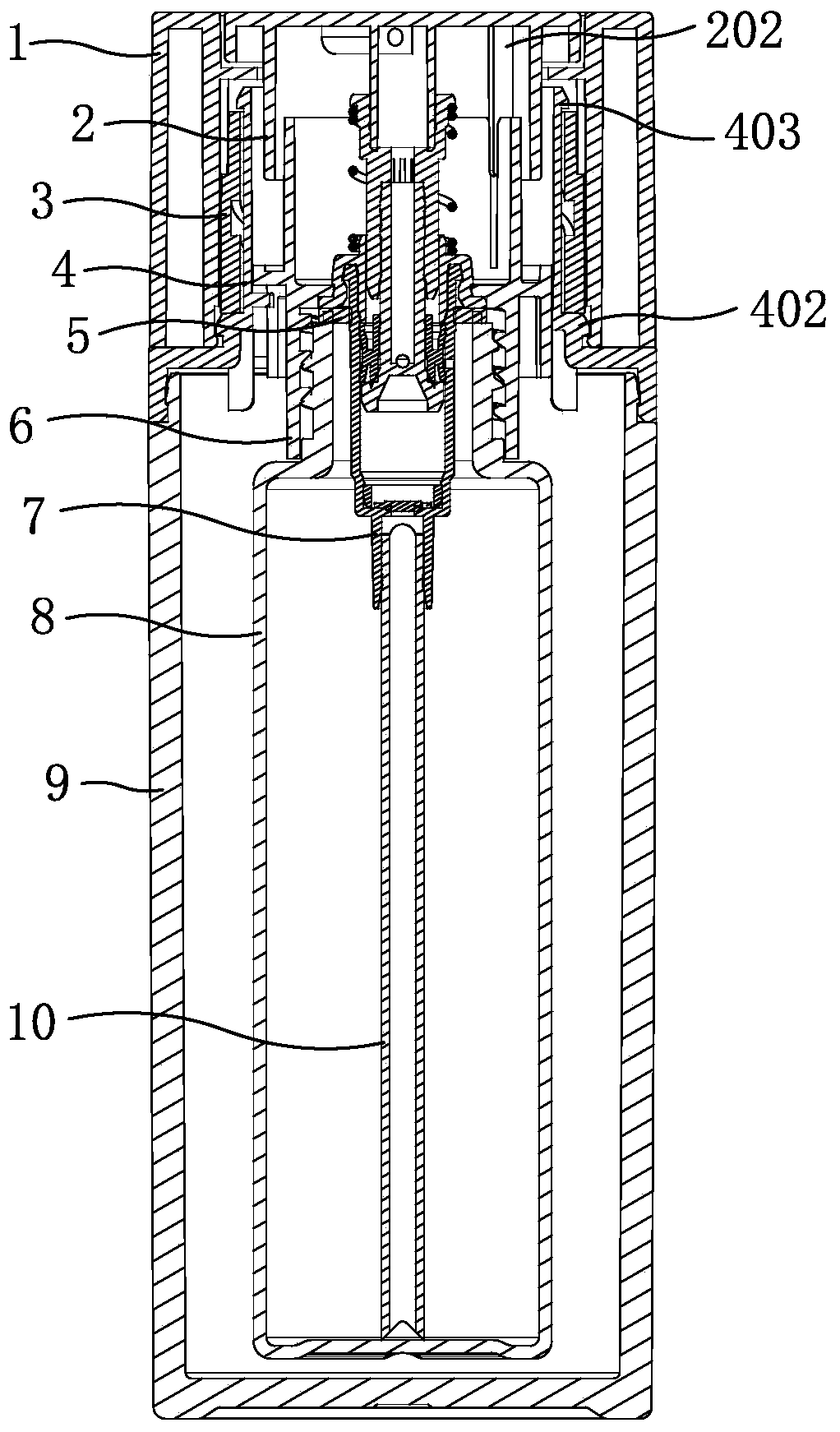

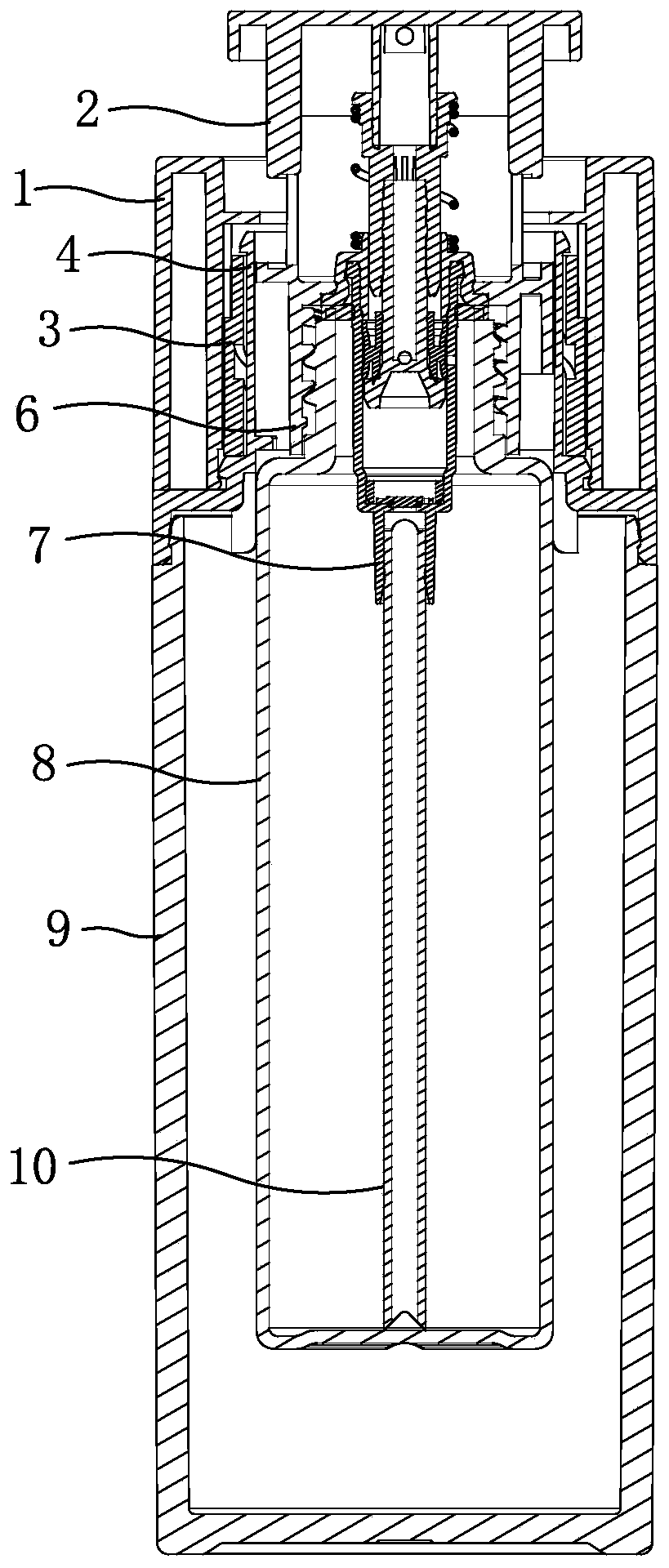

[0027] Now in conjunction with the accompanying drawings, the structure of the present invention will be further described. Such as Figure 1-Figure 11Shown, the outer bottle 9 of this rotary lotion bottle is provided with inner bottle 8, and the bottleneck of inner bottle is fixed on rotating circle 4 by big ring 6, and promptly the bottleneck of inner bottle is fixed in the lower thread circle of one end of big circle, The rotating circle is set on the bottle mouth of the outer bottle, the bottle mouth of the inner bottle is provided with a pump core assembly 7, the joint of the pump core assembly and the bottle mouth of the inner bottle is provided with a gasket 5, the valve stem and the head of the pump core assembly The cap 2 is connected, and the suction pipe 10 of the pump core assembly is located in the inner bottle; the head cap is usually hidden in the outer cover, and when in use, the outer cover is rotated, and the head cap extends out of the outer cover, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com