UV-cured electroplating silver paste coating and preparation method and application thereof

A technology of electroplating silver and paint, applied in the direction of polyester paint, epoxy resin paint, polyurea/polyurethane paint, etc., can solve the problems of poor wear resistance, smoothness and low saturation, and achieve easy construction and high film formation Smooth, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

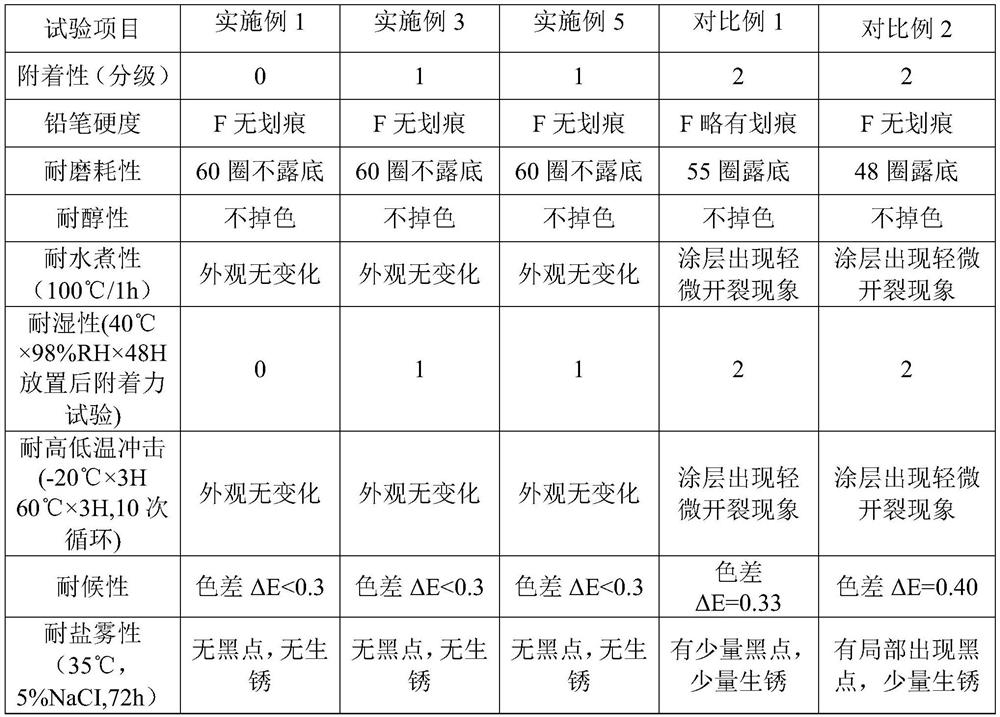

Embodiment 1

[0033] A UV hardening electroplating silver paste coating, comprising electroplating silver paste and UV varnish; said electroplating silver paste includes the following raw materials in parts by weight: 5 parts of aluminum silver paste, 20 parts of solvent, 1 part of surfactant and 20 parts of electroplating silver resin ; The weight ratio of the silver electroplating paste and UV varnish is 0.8:1.0; Preferably, the silver electroplating paste SB4102PM aluminum silver paste or TD-11EAC high brightness spray silver paste.

[0034] The UV varnish includes the following raw materials in parts by weight: 2 parts of propylene glycol methyl ether acetate, 30 parts of photocurable resin, 3 parts of dimethyl carbonate, 3 parts of photoinitiator, 0.1 part of adhesion promoter, 0.5 part of leveling agent And ketone 0.01 part.

[0035] Each part of the silver plating resin includes the following raw materials by weight: 15 parts of polyester acrylate, 30 parts of acrylic acid, 0.01 part...

Embodiment 2

[0053] A UV hardening electroplating silver paste coating, comprising electroplating silver paste and UV varnish; said electroplating silver paste includes the following raw materials in parts by weight: 7 parts of aluminum silver paste, 25 parts of solvent, 1.5 parts of surfactant and 23 parts of electroplating silver resin ; The weight ratio of the silver electroplating paste and UV varnish is 0.83:1.0; Preferably, the silver electroplating paste SB4102PM aluminum silver paste or TD-11EAC high brightness spray silver paste.

[0054] The UV varnish includes the following raw materials in parts by weight: 3 parts of propylene glycol methyl ether acetate, 38 parts of photocurable resin, 3.8 parts of dimethyl carbonate, 4 parts of photoinitiator, 0.25 part of adhesion promoter, and 0.6 part of leveling agent And ketone 1 part.

[0055] Each part of the silver plating resin includes the following raw materials by weight: 18 parts of polyester acrylate, 35 parts of acrylic acid, 0...

Embodiment 3

[0073] A UV hardening electroplating silver paste coating, comprising electroplating silver paste and UV varnish; said electroplating silver paste comprises the following raw materials in parts by weight: 8 parts of aluminum silver paste, 30 parts of solvent, 2 parts of surfactant and 25 parts of electroplating silver resin ; The weight ratio of the silver electroplating paste and UV varnish is 0.9:1.0; Preferably, the silver electroplating paste SB4102PM aluminum silver paste or TD-11EAC high brightness spray silver paste.

[0074] The UV varnish includes the following raw materials in parts by weight: 4 parts of propylene glycol methyl ether acetate, 45 parts of photocurable resin, 4.5 parts of dimethyl carbonate, 5 parts of photoinitiator, 0.5 part of adhesion promoter, and 0.7 part of leveling agent And ketone 2 parts.

[0075] Each part of the silver plating resin includes the following raw materials by weight: 20 parts of polyester acrylate, 40 parts of acrylic acid, 0.5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap