Shaft part surface strengthening device capable of realizing constant-pressure self-balance and machine tool

A shaft parts, surface strengthening technology, applied in the field of shaft parts processing, can solve problems affecting processing quality, cylindricity error, radial imbalance, etc., to achieve the effect of ensuring rolling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

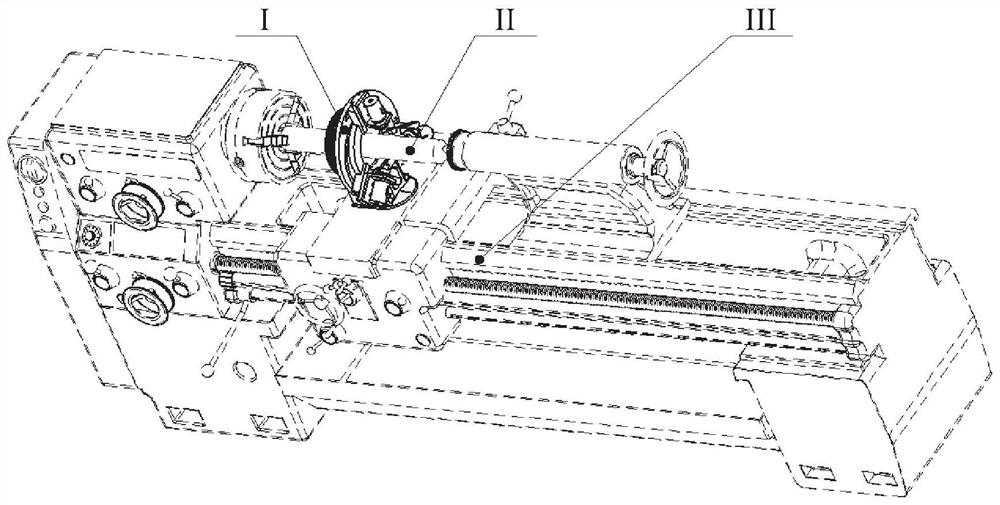

[0043] In a typical embodiment of the present invention, such as figure 1 As shown, a surface strengthening device for shaft parts that can achieve constant pressure self-balancing is proposed. The surface strengthening device I is installed in the middle of the lathe III, connected with the tool rest of the lathe through a middle slider, and can be driven by the tool rest for feeding. Movement, and then strengthen the surface of the shaft part II to be processed. The axial feed rate can be realized at 0.02-2mm / r, and the rotation speed of the parts is 10-1000rpm.

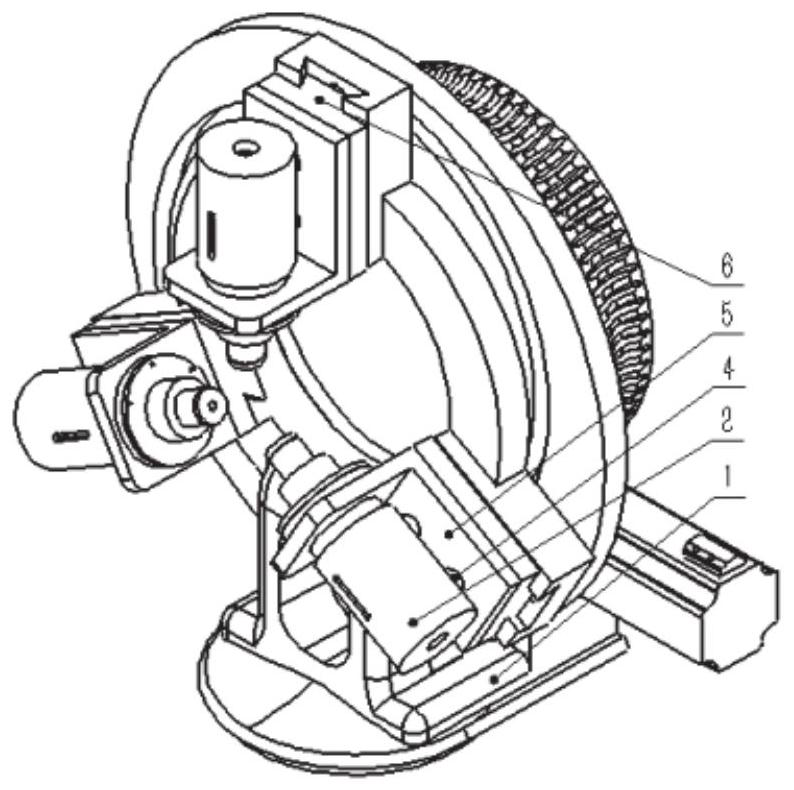

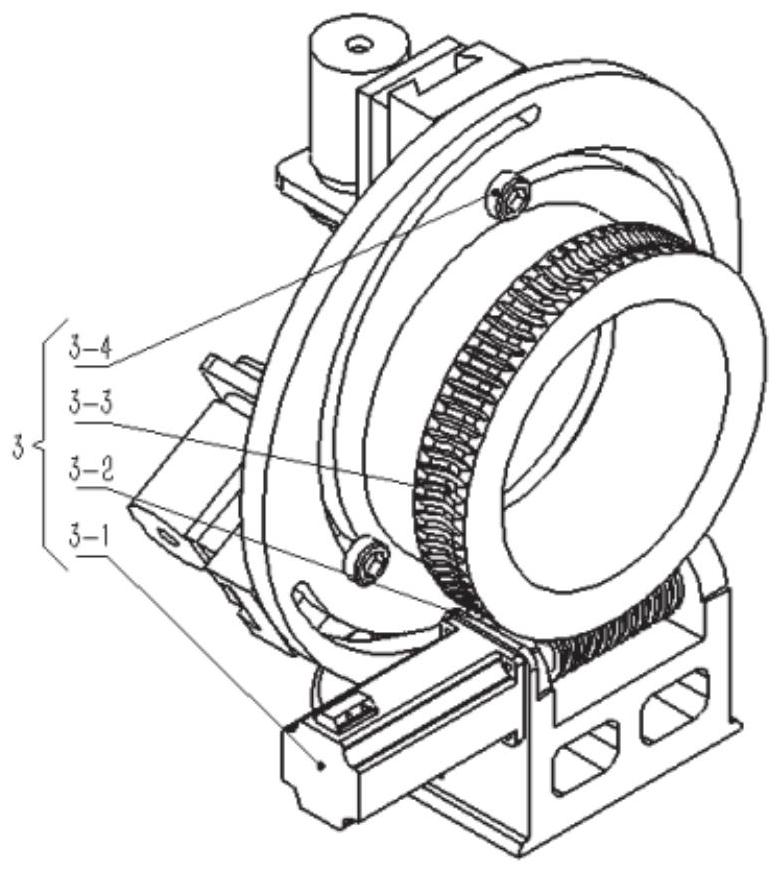

[0044] Surface strengthening device I such as figure 2 , image 3 As shown, it consists of a base 1, a rolling device 2, a position and pressure adjusting device 3, a connecting bolt 4, a mounting seat 5, and a slider 6. The ultrasonic pulse power supply is omitted in the figure.

[0045] The rolling device is equipped with a plurality of rollers, which form a circle, and the surface of the shaft parts is sequ...

Embodiment 2

[0069] This embodiment provides a machine tool, including the above-mentioned surface strengthening device for shaft parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com