Rapid installation equipment for lifeline stand column

A technology for installing equipment and lifelines, applied in the processing of building materials, construction, building structure, etc., can solve the problems of large limitations of lifeline columns, low assembly efficiency, multiple labor costs, etc., to improve installation efficiency and ensure safety. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

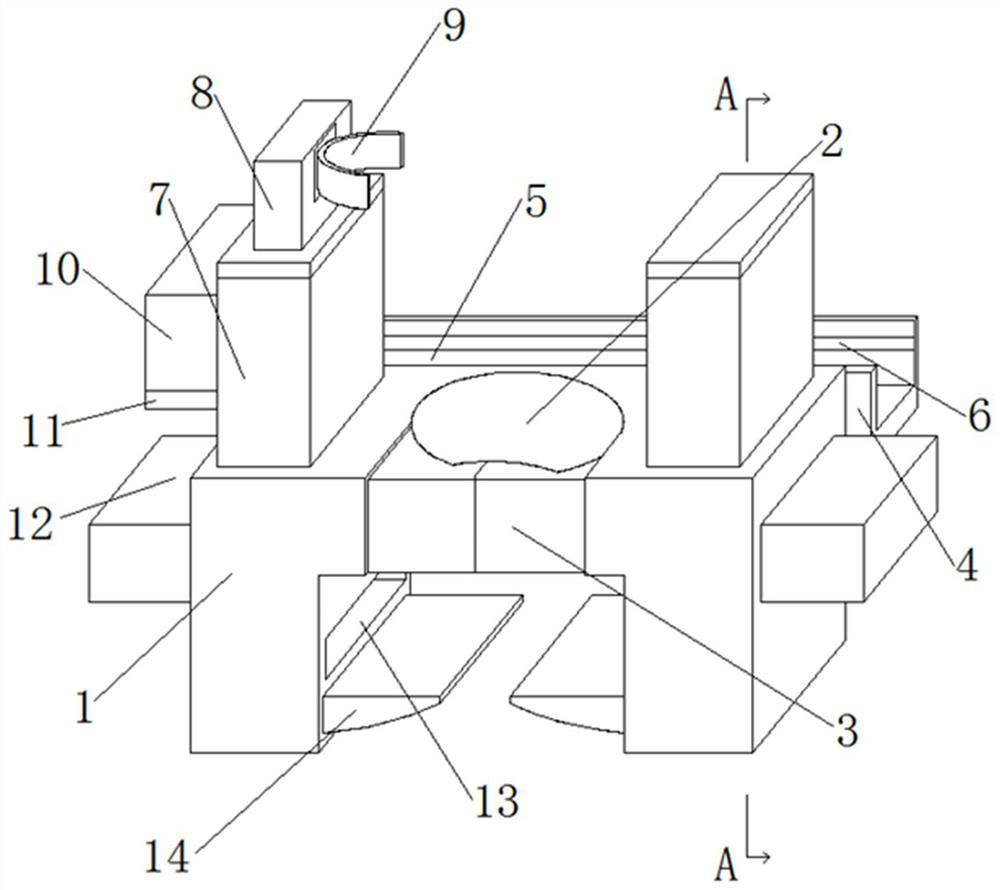

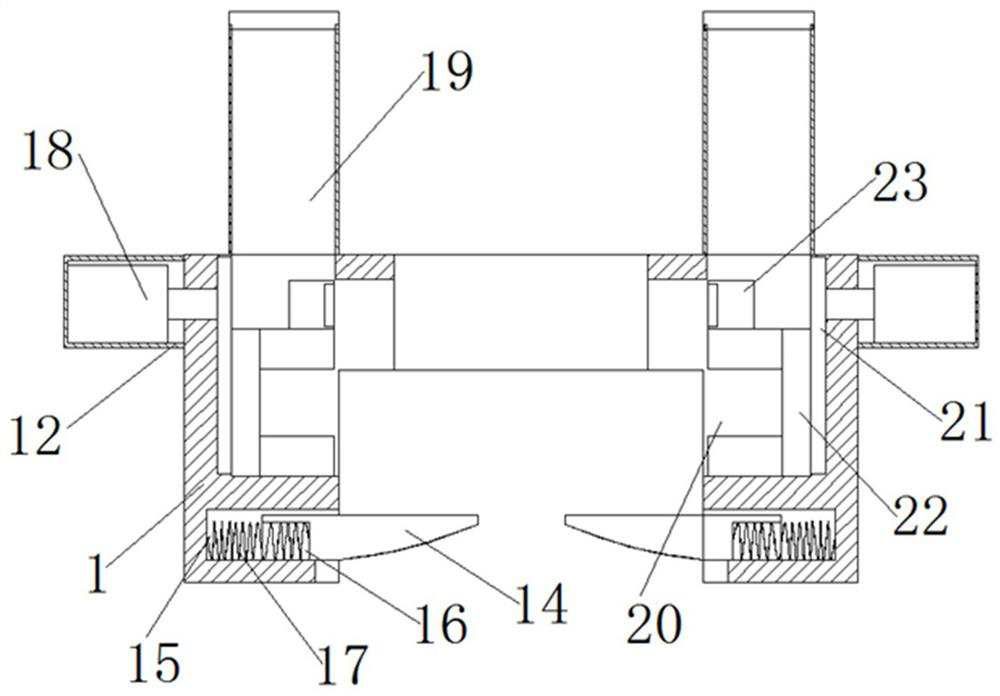

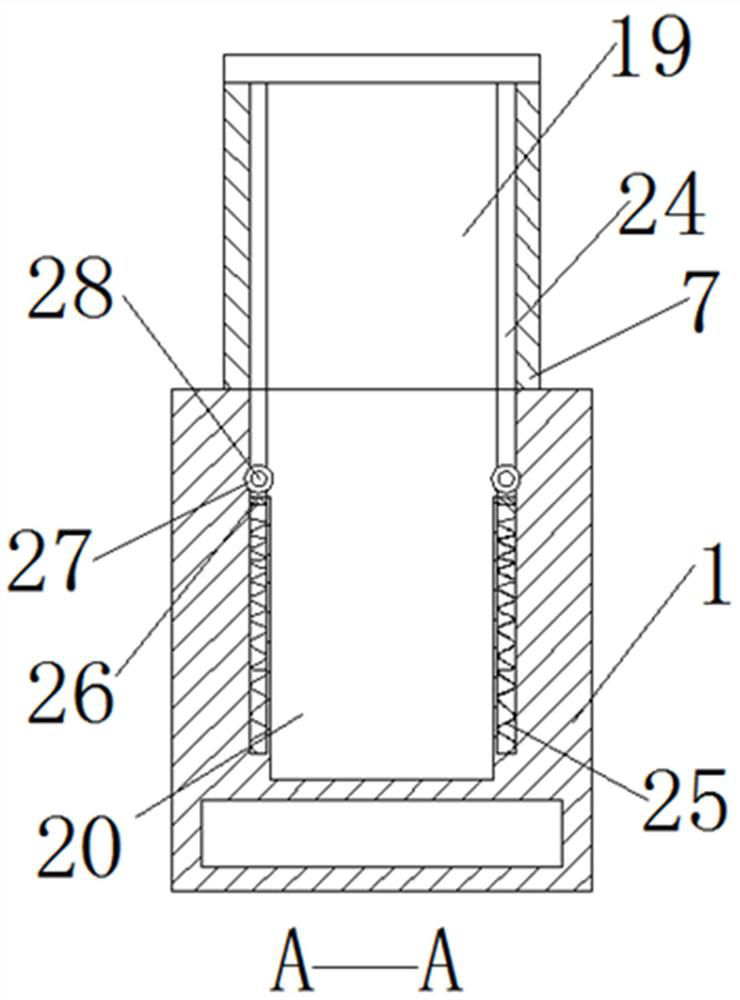

[0030] Such as Figure 1-6As shown, a quick installation device for a lifeline column includes a device body 1, the device body 1 is arranged on a steel beam 38, a jack 2 is arranged on the device body 1, and a movable block 3 is arranged on one side of the jack 2 The two sides of the jack 2 are provided with a placement box 7, and one side of the placement box 7 is provided with a control box 10, and the bottom of the control box 10 is provided with a storage battery 11, and the inside of the device body 1 is provided with a movable chamber 20. Both sides are provided with draw-in groove 24, and the bottom of draw-in groove 24 is provided with second spring 25, and the top of second spring 25 is provided with support plate 26, and bolt 28 is placed on support plate 26, several groups of bolts 28 are placed on support plate 26, after the uppermost bolt 28 is installed, through the elasticity of the second spring 25, the lower bolt 28 can be overlapped with the position before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com