Back rib type composite board

A composite board and back rib type technology is applied in the field of composite boards to achieve the effects of improving utilization, strong strength and enhancing product practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

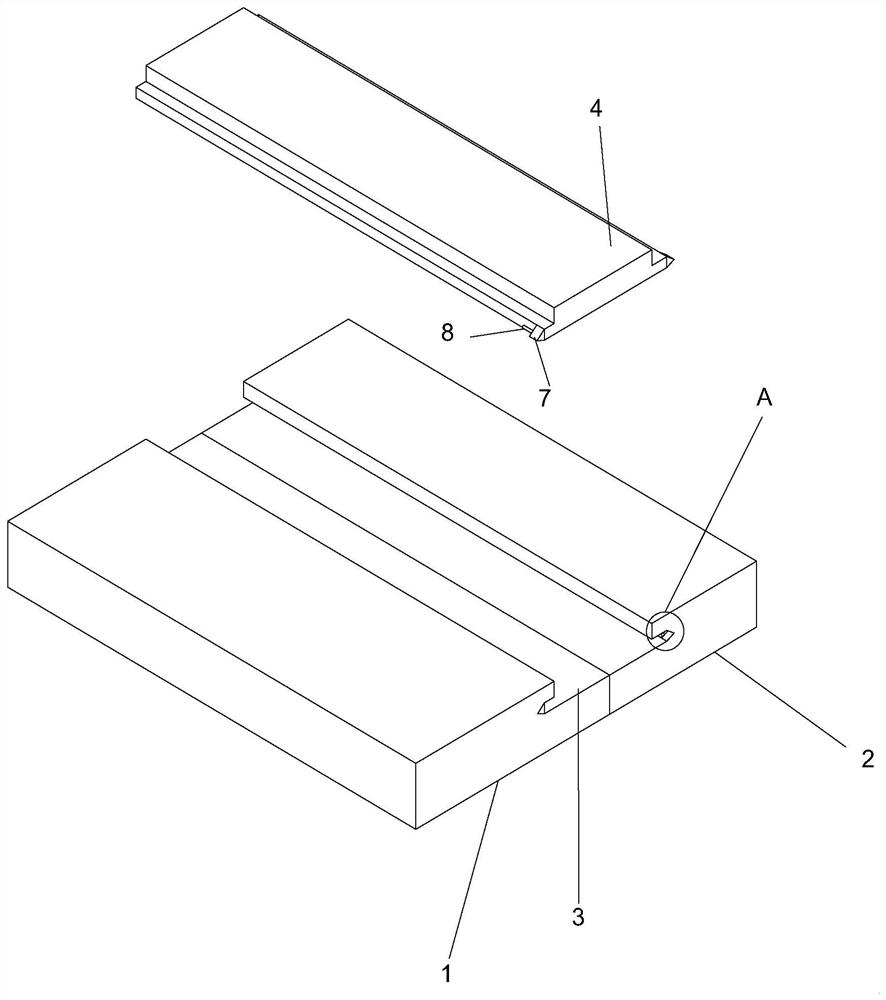

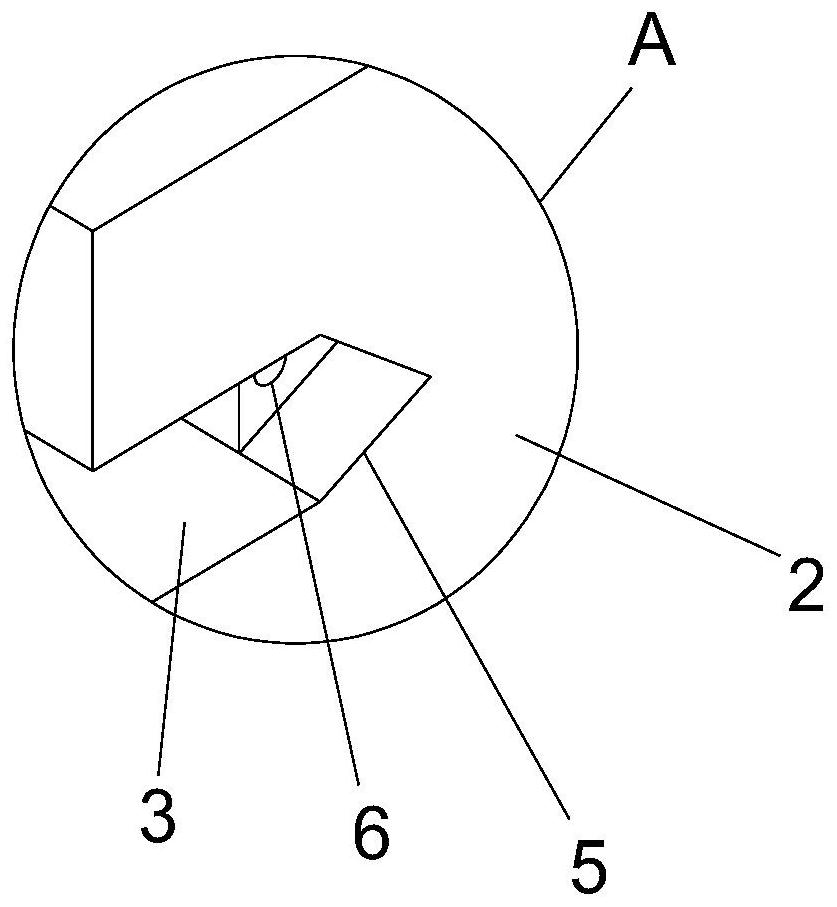

[0036] A back-reinforced composite panel, please refer to Figure 1-4 , including A board 1 and B board 2, the sides of A board 1 and B board 2 are closely attached, and a back board 4 is compounded on the back of the joint line of A board and B board, A board 1 and B board 2 The bottom of the adjacent side is symmetrically provided with an "L"-shaped card slot 3, and the inside of the two card slots 3 is connected with a back plate 4 with a "convex" shape in section, and the back plate 4 is compatible with the inside of the two card slots 3 Matched and fixed by adhesive, the adjacent side of A board 1 and B board 2 is provided with a connection groove 5 communicating with the card groove 3, the inside of the connection groove 5 is provided with a connection hole 6, and the two ends of the back board 4 are fixedly installed with The connection block 7 corresponding to the connection groove 5, the two connection blocks 7 are installed with the clamping column 8 that can be enga...

Embodiment 2

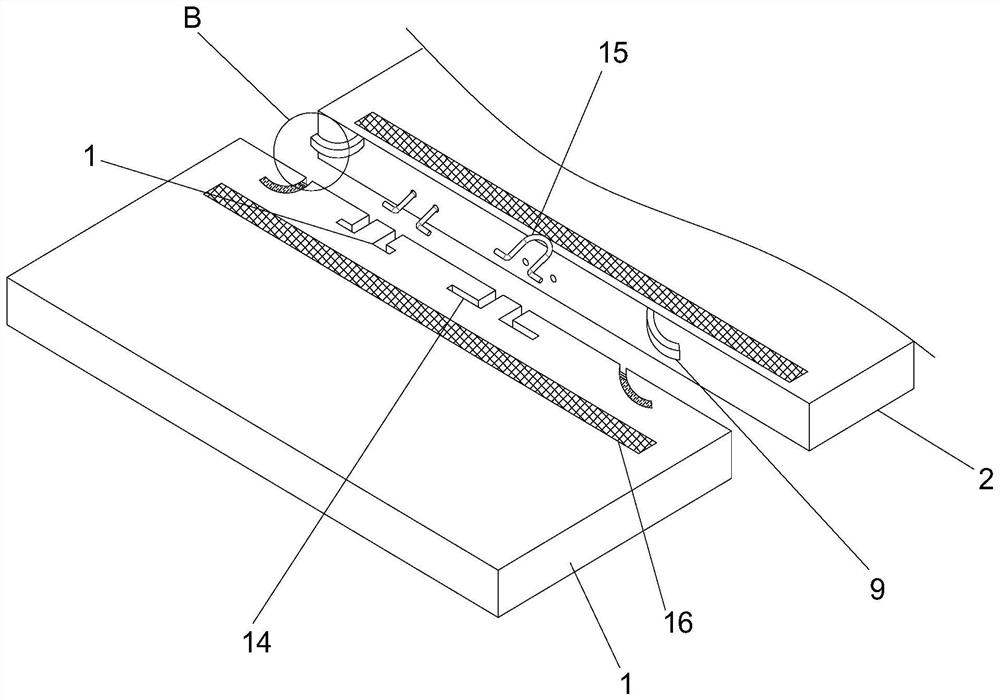

[0042] Embodiment two: on the basis of embodiment one, refer to Figure 1-3 There are cable grooves 14 on the side of plate A 1, two cable grooves 14 form a group, and the interior of each group of "L" shaped cable grooves 14 extends away from each other, and the interior of board B 2 corresponding to cable grooves 14 is inlaid with Anchor piece 15, the anchor piece 15 is "U" shape, and the two ends of the anchor piece 15 extend through the inside of the B board 2 and extend outward toward the direction away from each other. adaptation.

[0043] Working principle: When board A 1 and board B 2 are docked, after the two ends of the anchor 15 are squeezed to the middle, insert the two ends of the anchor 15 into the corresponding cable groove 14, when the anchor 15 is inserted into the corresponding cable groove 14 After the internal post-recovery deformation is clamped to both ends of the cable groove 14, the two ends of the anchor piece 15 recover and deform toward the inside o...

Embodiment 3

[0044] Embodiment three: on the basis of embodiment two, please refer to Figure 1-4 , The interior of the adjacent side of A board 1 and B board 2 is inlaid with a rectangular protective net 16, and the two ends of the anchor 15 inside the inlaid B board 2 first pass through the filter holes of the anchor 15 and then extend outward to B board 2 exterior.

[0045] Working principle: By setting the protective net 16 inside the A-board 1 and the B-board 2, the protective net 16 not only improves the overall shape strength of the board between the A-board 1 and the B-board 2, but also the protective net 16 is inlaid with the B-board 2. The inner anchor 15 further stabilizes the connection, strengthens the connection strength between the anchor 15 and the B board 2, indirectly promotes the connection strength between the A board 1 and the B board 2, and at the same time improves the connection between the A board 1, B board 2 and the back. The board 4 forms the overall board stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com