An electrode water-cooled plate used in a g8.5h substrate glass pool furnace and its manufacturing method

A technology of electrode water cooling and manufacturing methods, which is applied in glass furnace equipment, glass manufacturing equipment, furnaces, etc., can solve the problems of electrode water cooling plate bottom plate and sleeve weld seam leakage, etc., and achieve the effect of consistent processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

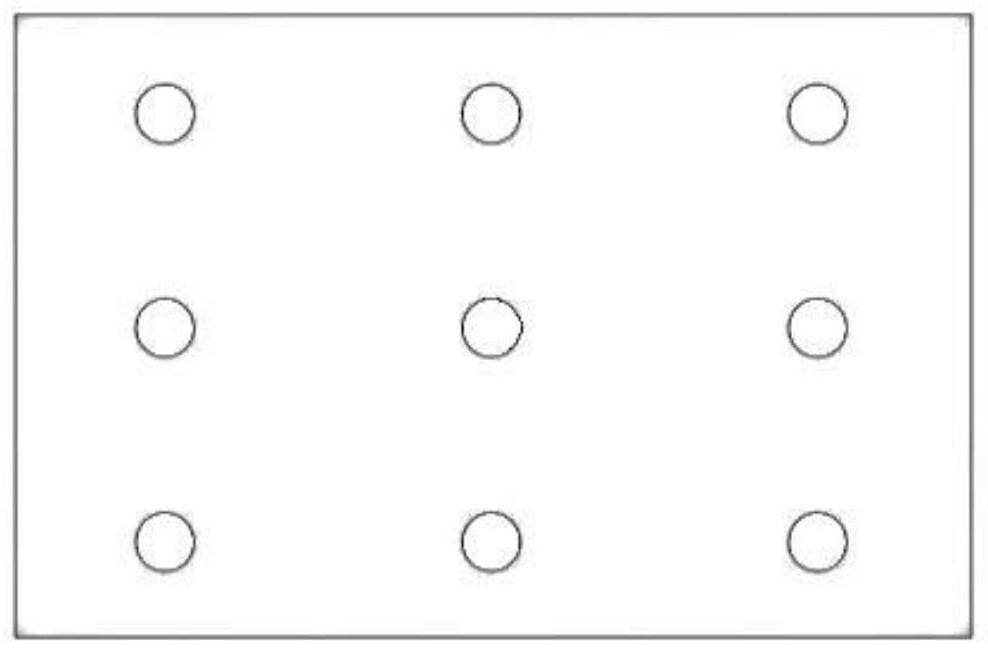

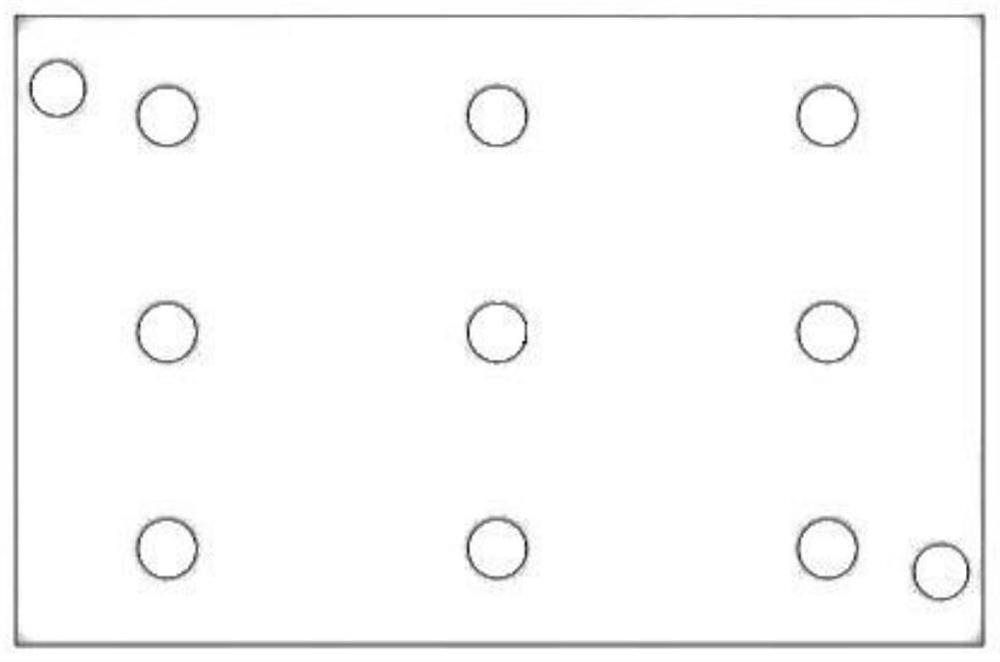

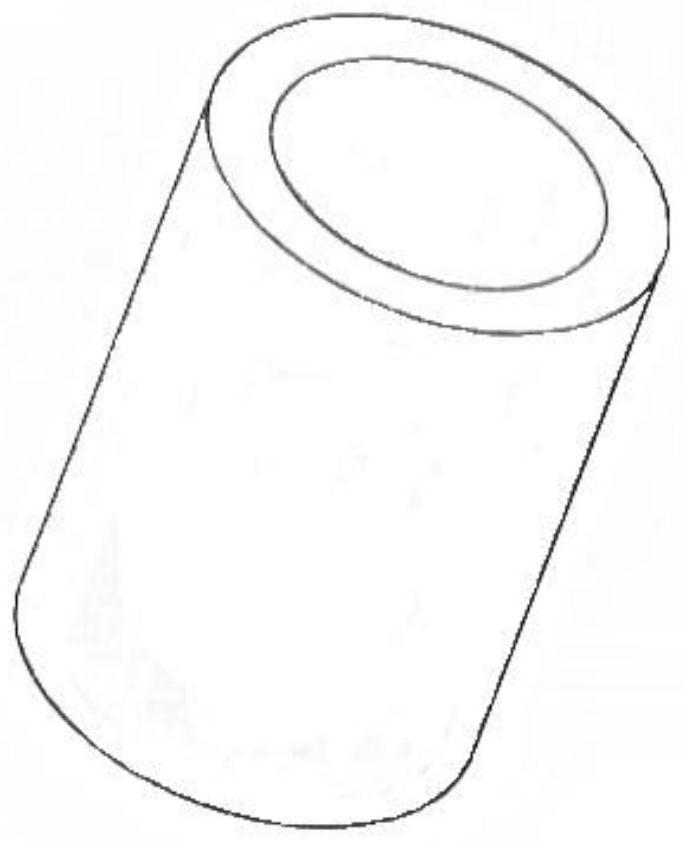

[0039] Such as Figure 2a and Figure 2b As shown, an electrode water-cooled plate used in a G8.5H substrate glass pool furnace optimizes and improves several pairs of sleeve mounting holes symmetrically arranged on the plate surface of the bottom plate 1 and the bottom plate 2 of the electrode water-cooled plate, and the original The cylindrical through hole is changed to a tapered through hole, preferably with an angle of 45°. The large mouth end of the through hole is set toward the outside of the plate surface. The diameter of the large mouth end is the same as the original cylindrical hole diameter. The sleeves 3 are arranged in pairs In the reduction-type through hole, the two ends of the sleeve 3 are respectively sealed and connected with the through hole on the same side; the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com