Differential gear

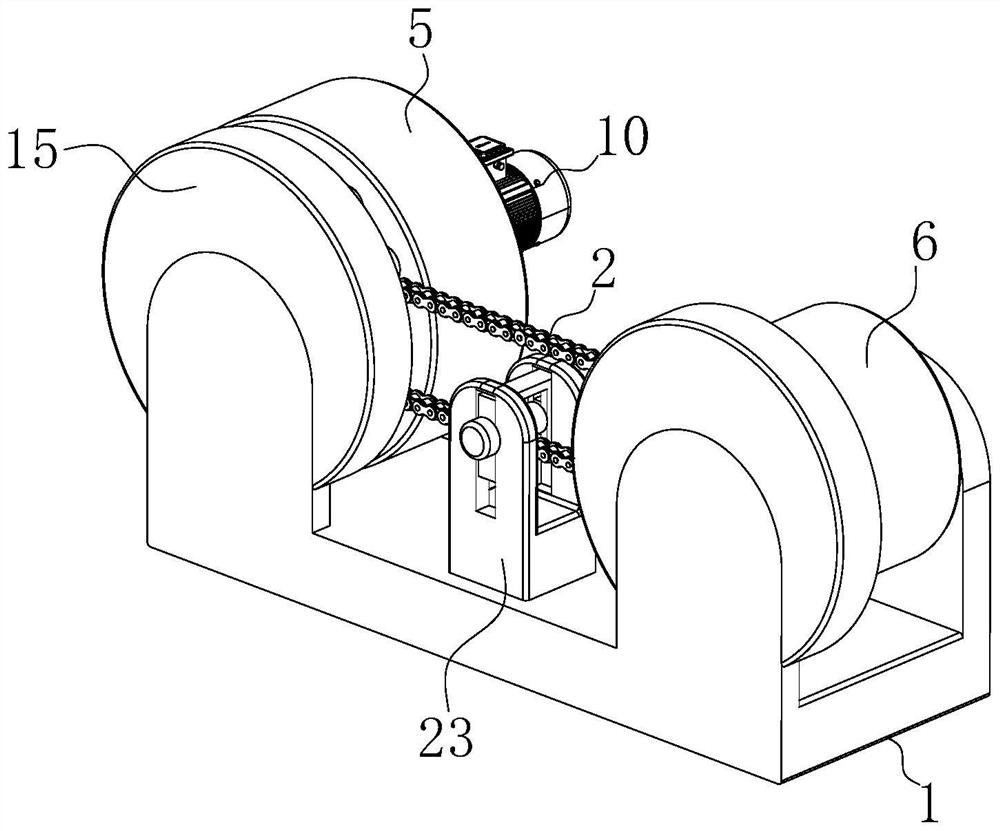

A technology of differential transmission and equipment, applied in the direction of transmission, mechanical equipment, hoisting device, etc., can solve the problems of inconvenient winding, stuck, unable to adjust the transmission ratio freely and quickly, and reduce switching stuck and, Improves service life and facilitates resetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

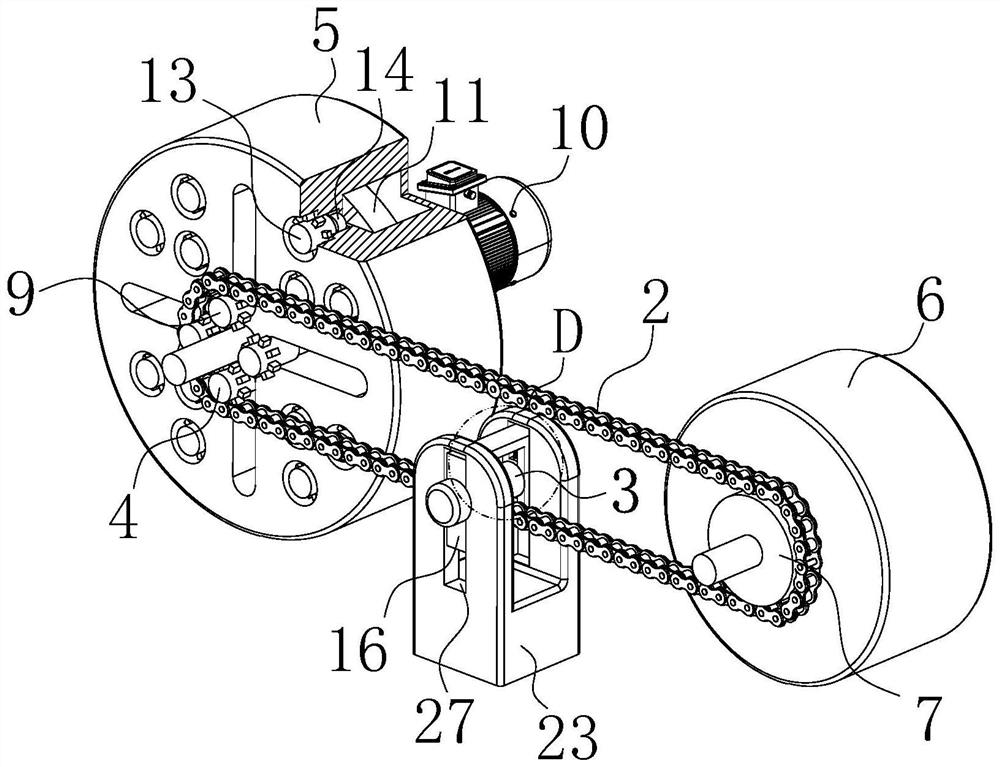

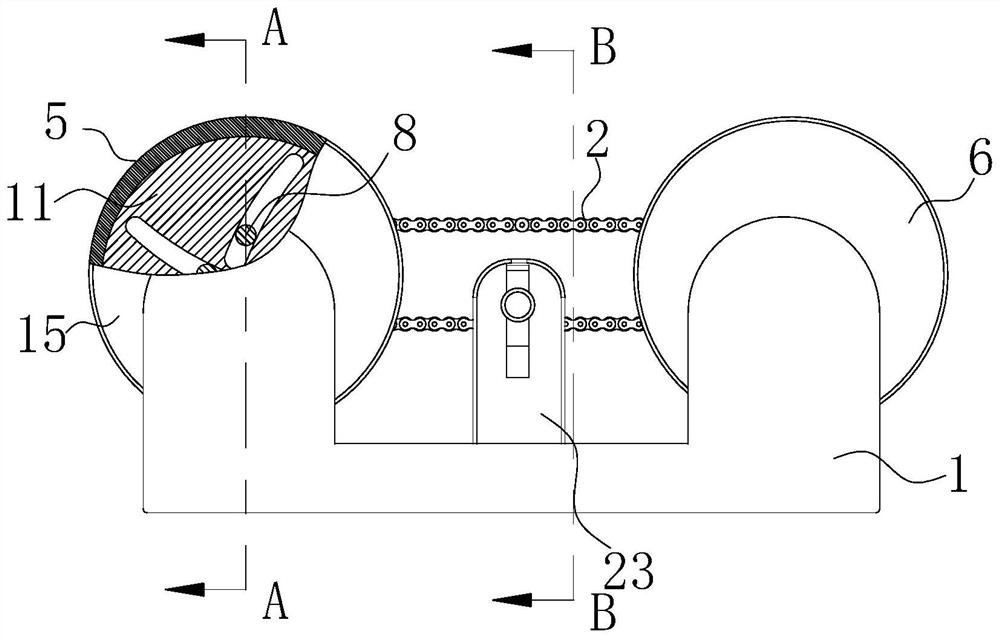

[0029] As an embodiment of the present invention, a rotating cavity is opened inside the drive plate 5 ; a guide plate 11 is rotatably connected to the inside of the rotating cavity; Guide grooves are provided, and the sliders 8 are slidably connected to the inside of the corresponding guide grooves; the rear end surface of the rotating cavity is fixedly connected with the second motor 12 , and the output shaft of the second motor 12 is fixedly connected with the guide plate 11 . When working, by setting the guide plate 11, through the rotation of the control element, that is, the second motor 12, the second motor 12 will drive the guide plate 11 to rotate, and the slider 8 on the surface will be driven by the guide plate 11 and the inside of the corresponding guide groove Sliding, by designing the guide groove as an involute trend structure, and cooperating with the sliding block 8 inside the sliding groove on the surface of the driving disc 5, the automatic adjustment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com