Cavitation pipe liquid flow test method

A test method and cavitation technology, applied in fluid dynamics test, machine/structural component test, measuring device, etc., can solve problems such as high complexity of cavitation pipe liquid flow test system, and reduce inlet pressure and outlet pressure. The effect of pressure requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

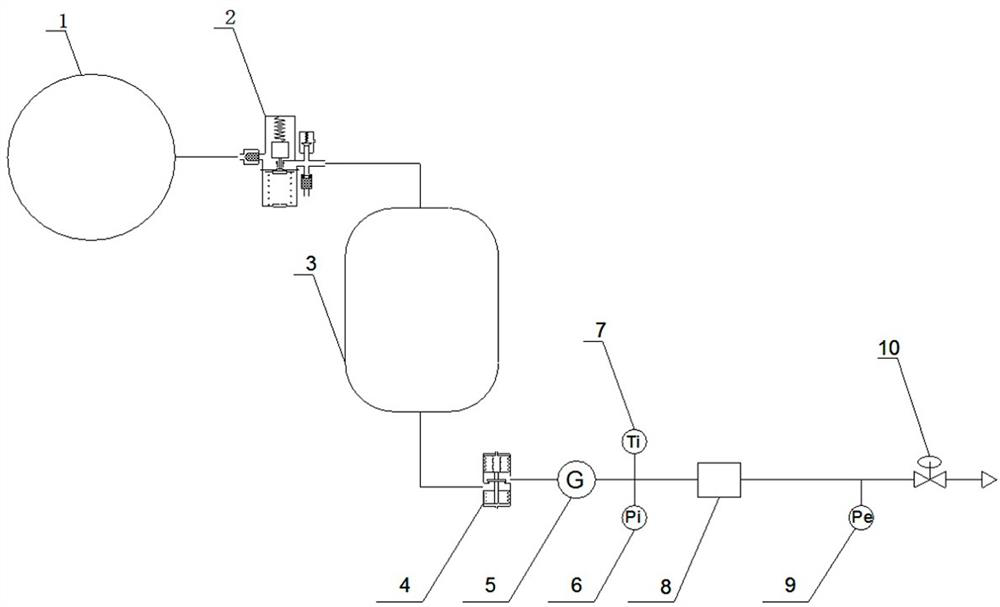

Image

Examples

Embodiment 1

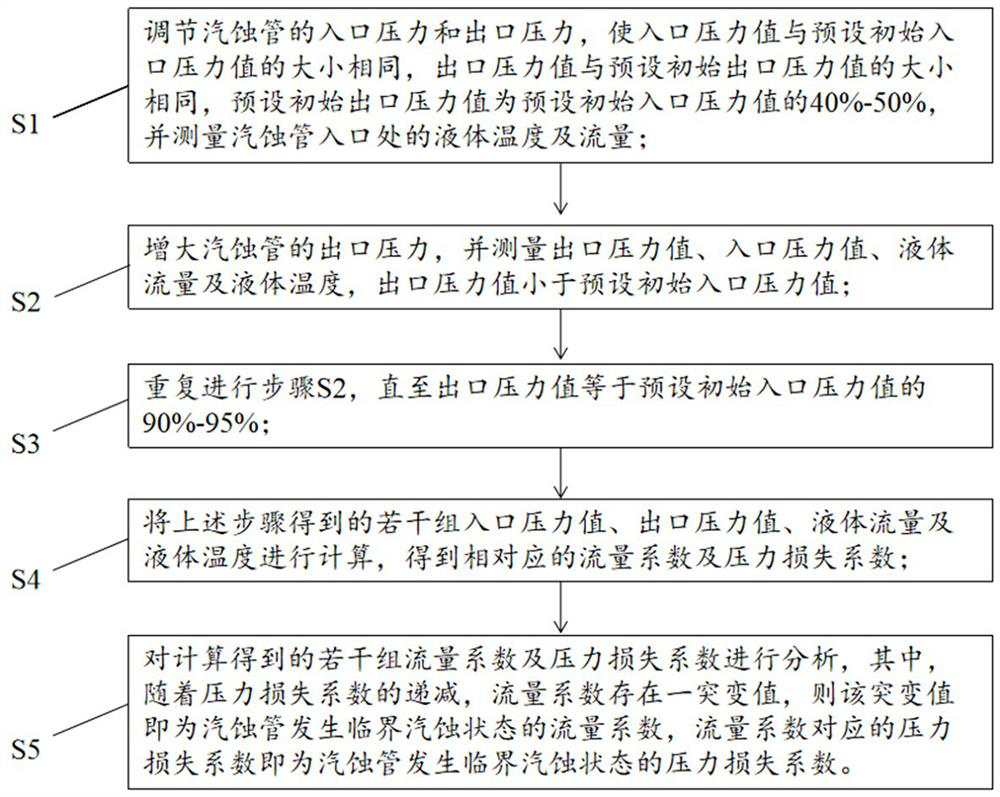

[0050] Such as figure 2 As shown, the present embodiment provides a cavitation pipe liquid flow test method, comprising the following steps:

[0051] S1. Adjust the inlet pressure and outlet pressure of the cavitation pipe so that the inlet pressure value is the same as the preset initial inlet pressure value, the outlet pressure value is the same as the preset initial outlet pressure value, and the preset initial outlet pressure value is the preset value. Set 40%-50% of the initial inlet pressure value, and measure the liquid temperature and flow at the inlet of the cavitation pipe;

[0052] S2. Increase the outlet pressure of the cavitation pipe, and measure the outlet pressure value, inlet pressure value, liquid flow rate and liquid temperature, so that the outlet pressure value is less than the preset initial inlet pressure value;

[0053] S3. Repeat step (2) until the outlet pressure value is equal to 90%-95% of the preset initial inlet pressure value;

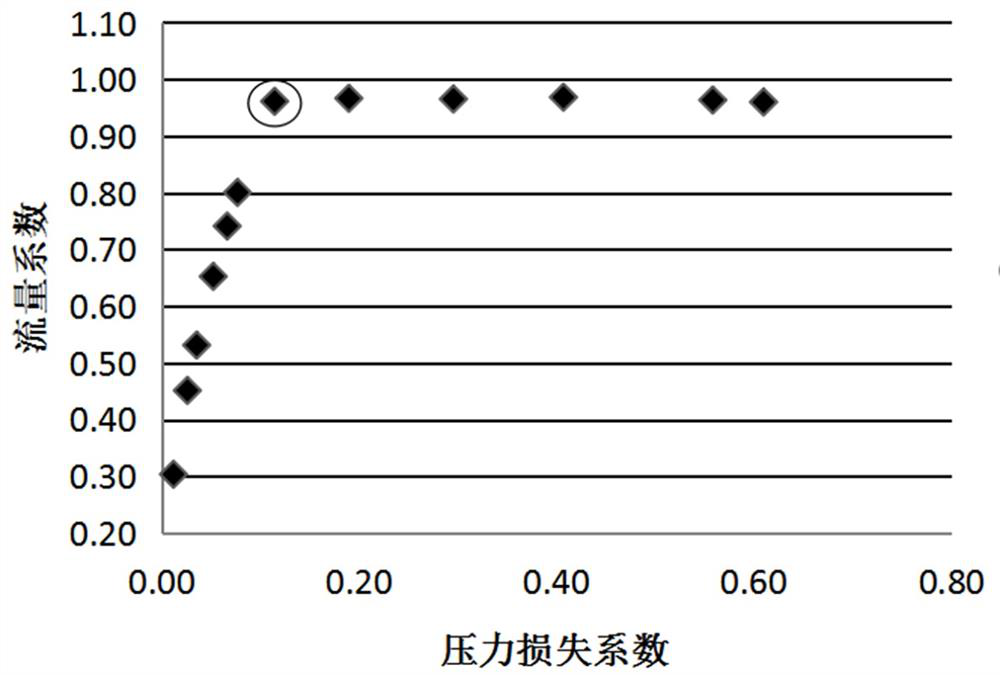

[0054] S4. Cal...

Embodiment 2

[0089] Such as Figure 4 As shown, the present embodiment provides a cavitation pipe liquid flow test method, comprising the following steps:

[0090] S1. Adjust the inlet pressure and outlet pressure of the cavitation pipe so that the inlet pressure value is the same as the preset initial inlet pressure value, the outlet pressure value is the same as the preset initial outlet pressure value, and the preset initial outlet pressure value is the preset value. Set 90%-95% of the initial inlet pressure value, and measure the liquid temperature and flow at the inlet of the cavitation pipe;

[0091] S2. Reduce the outlet pressure of the cavitation pipe, and measure the outlet pressure value, inlet pressure value, liquid flow rate and liquid temperature;

[0092] S3. Repeat step (2) until the outlet pressure value is equal to 45%-50% of the preset initial inlet pressure value;

[0093] S4. Calculate several sets of inlet pressure values, outlet pressure values, liquid flow rates an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com