Ejection assembly of cleaning device and cleaning device

A cleaning device and component technology, which is applied in the direction of cleaning filter devices, cleaning equipment, vacuum cleaners, etc., can solve problems such as flying dust, and achieve the effect of avoiding flying dust and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

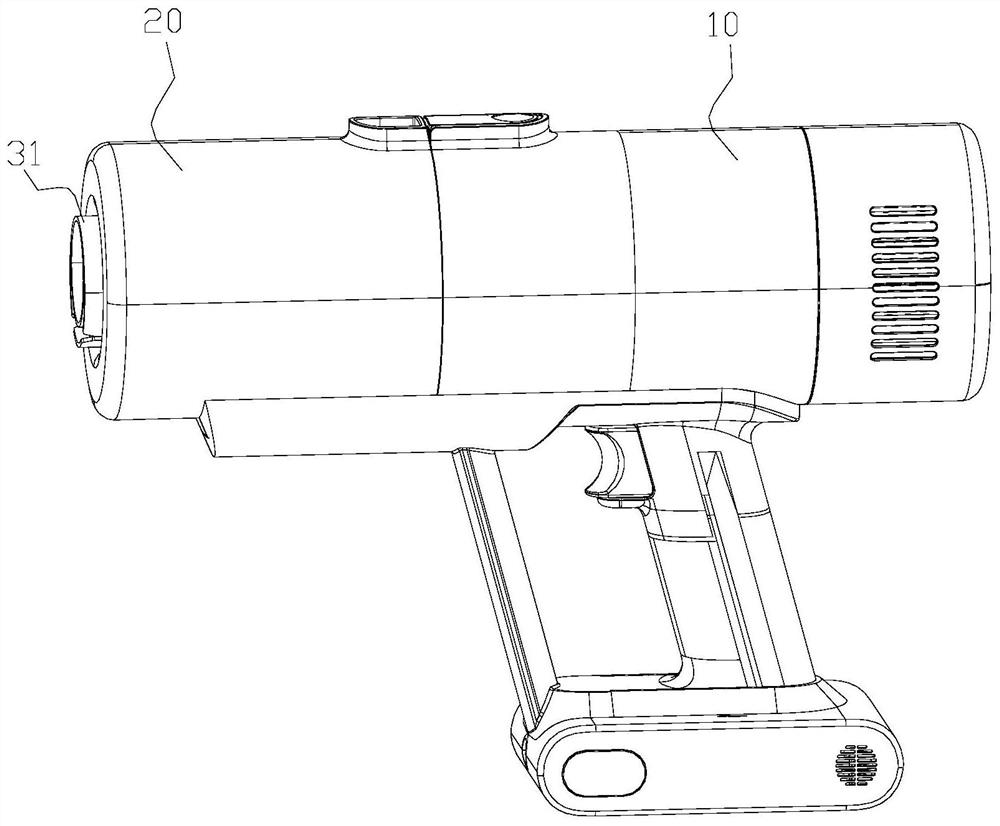

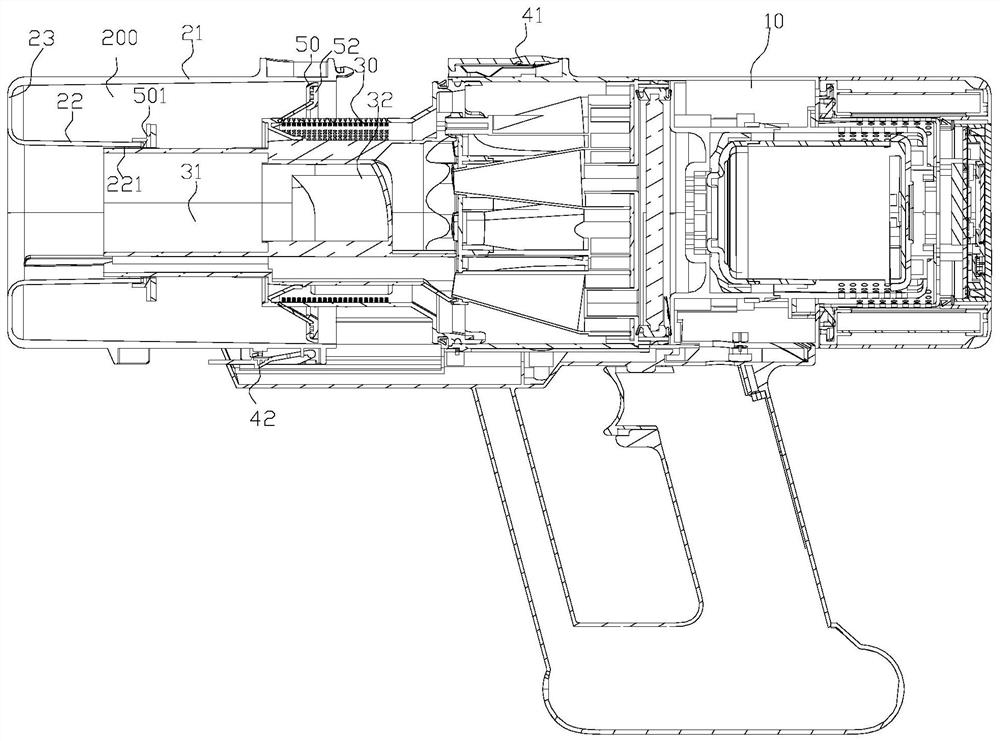

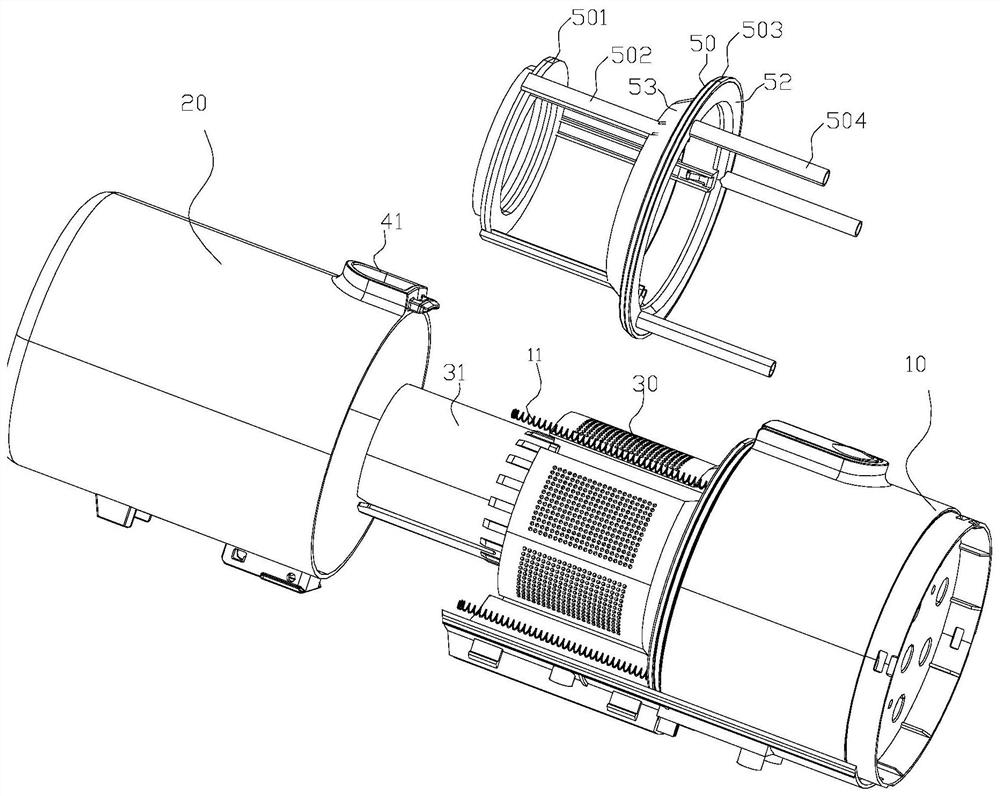

[0033]referenceFigure 1 - Figure 6 The ejection assembly of a cleaning device includes an elastic member 11, a ring member 50.

[0034]The elastic member 11 is mounted in the main body portion 10 of the cleaning device, the elastic member 11 is a compression spring, and when the dust cup 20 is mounted on the main body portion 10, the elastic member 11 is in a compressed state. The annular member 50 is provided with a guide post 504, and the elastic member 11 elongates in the axial direction of the guide post 504 to eject the ring member 50. The dust cup 20 is in contact with the annular member 50, and the elastic member 11 is released after the release ring 50 is moved and the abutting dust cup 20 is bounted to the detachable position. The annular member 50 is provided with a sterling portion 53, and the surface of the elastic member 11 can be automatically scratched simultaneously.

[0035]The cleaning device includes a main body portion 10, an intake conduit 31, a rotating conduit 32, a...

Embodiment 2

[0058]referenceFigure 7 - Figure 10 , A cleaning device of the ejection module includes an elastic member 11, a ring member 50, and a dust cup 20.

[0059]The elastic member 11 is mounted in the main body portion 10 of the cleaning device, the elastic member 11 is a compression spring, and when the dust cup 20 is mounted on the main body portion 10, the elastic member 11 is in a compressed state. The inner portion of the annular member 50 is provided with a guide post 504, and the elastic member 11 elongates in the axial direction of the guide post 504 to eject the ring member 50. The dust cup 20 is in contact with the annular member 50, and the elastic member 11 is released after ejection of the annular member 50 and pushes the implantable dust cup 20 to the detachable position. . The annular member 50 is provided with a sterling portion 53, and the surface of the elastic member 11 can be automatically scratched simultaneously.

[0060]The cleaning device includes a main body portion 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com