Pig-raising wastewater energy recovery device

A technology for energy recovery and waste water, which is applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc. It can solve the problems of inability to separate solids and liquids for recovery and treatment, and achieve the effect of ensuring the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

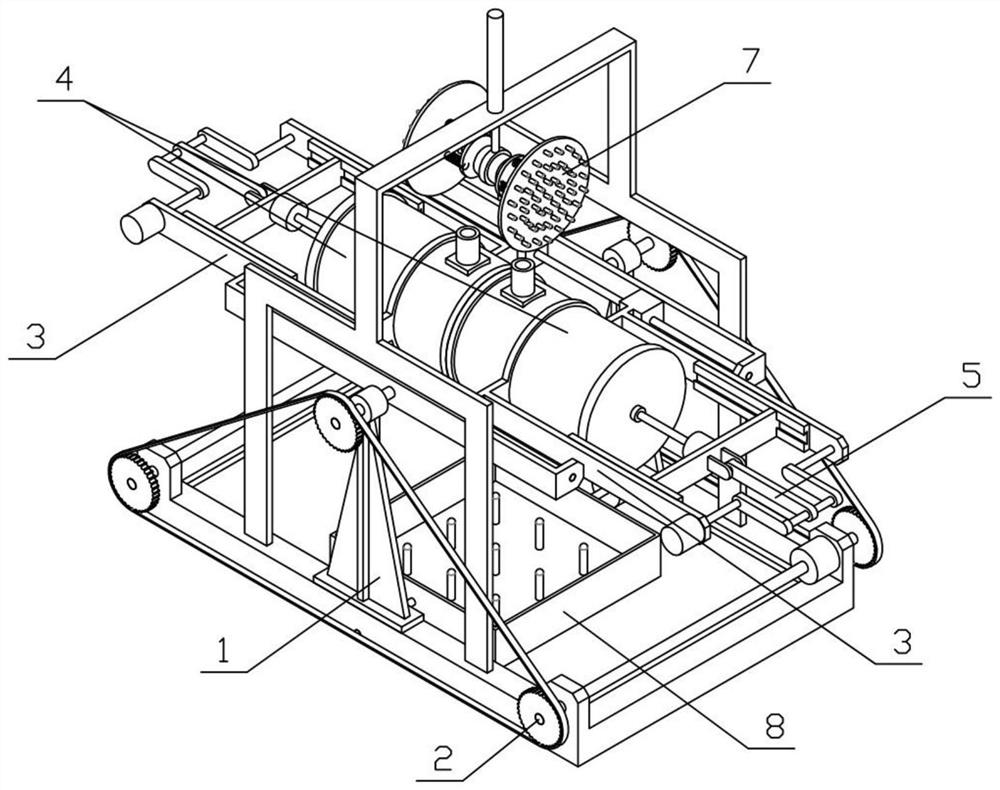

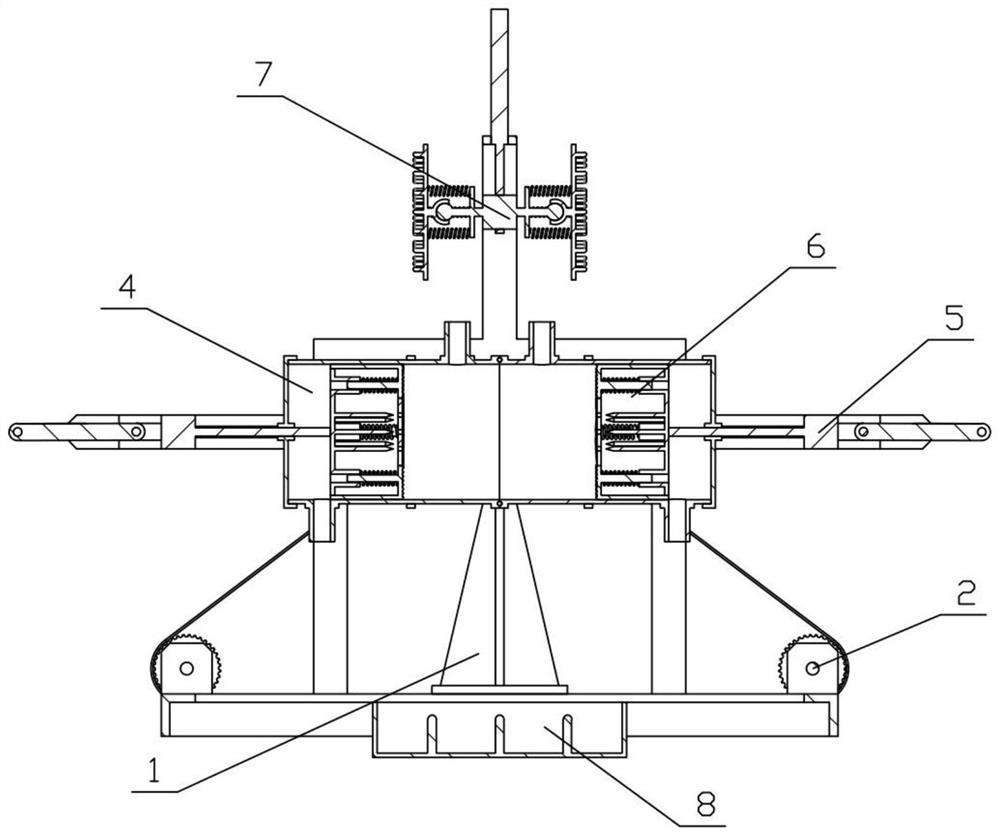

[0035]Bonded belowFigure 1 to 12In the present embodiment, a pig wastewater energy recovery device includes a device bracket 1, a swing mechanism 2, mounting bracket 3, an extruder 4, a push mechanism 5, an extrusion mechanism 6, and a cleaning mechanism 7, and the apparatus bracket 1 The swing mechanism 2 is connected to the swing mechanism 2, and two mounting brackets 3 are connected to the swing mechanism 2, and the two mounting brackets 3 are fixedly connected to the extruder 4, and the two extruder 4 is connected to the push mechanism 5, two The push mechanism 5 is fixedly connected to the extrusion mechanism 6, and the two extrusion mechanisms 6 are slidably coupled to the two extruded cylinder 4, and the device bracket 1 is fixedly connected to the cleaning mechanism 7; the two promotion mechanism 5 can be passed. Pushing the two extrusion mechanisms 6 in two extruded cylinder 4, the two extrudation mechanisms 6 are extruded by the solids and liquids in pig waste water, while...

specific Embodiment approach 2

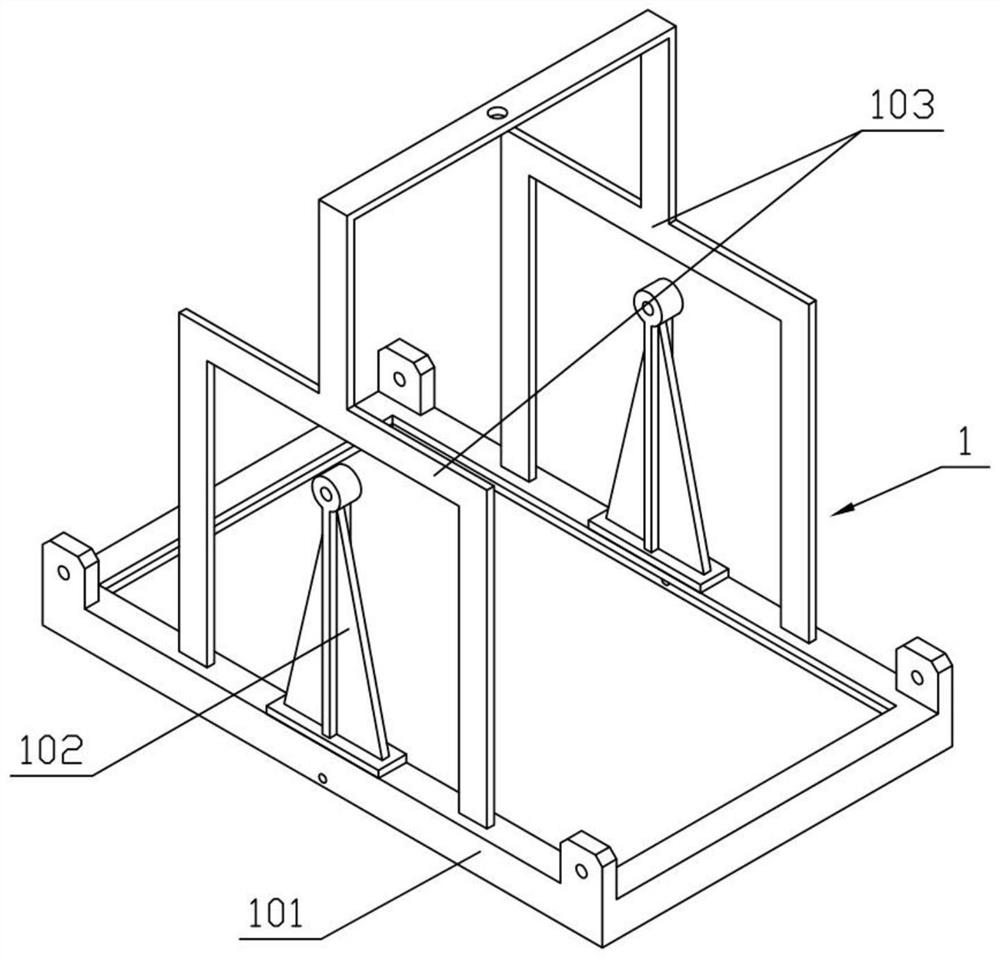

[0037]Bonded belowFigure 1 to 12In the present embodiment, the present embodiment will further explain the embodiment, and the apparatus holder 1 includes a bottom bracket 101, a swing bracket 102, and a support bracket 103, and the bottom bracket 101 is fixed to the left and right sides of the bottom bracket 102, the bottom bracket The central portion of 101 is fixedly connected to the support bracket 103.

specific Embodiment approach 3

[0039]Bonded belowFigure 1 to 12In the present embodiment, the present embodiment will further explain the second embodiment, and the swing mechanism 2 includes a swing motor I201, a swing shaft 202, a swing holder 203, a sliding post 204, and a transverse motor 205, and the swing motor I201 is fixedly connected at the bottom. On the bracket 101, two swing shafts 202 are provided with two, and the two swing shafts 202 are rotatably coupled to the two swing brackets 102, and the two swing shafts 202 each other and the output shaft drive of the swing motor I201, and the two swing shafts 202 The swing bracket 203 is fixedly connected, where one swing bracket 203 is fixedly connected to the sliding post 204, and the other swing bracket 203 is fixedly connected to the transverse motor 205.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com