A combination fixture for drill bit production and processing

A combination fixture and drill clamp technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the inconvenient operation of drill clamping and disassembly, affect the quality and efficiency of drill bit processing, and cannot meet the requirements of drill bit processing Requirements and other issues to achieve the effect of facilitating processing or inspection, improving service life and working reliability, and preventing wear and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

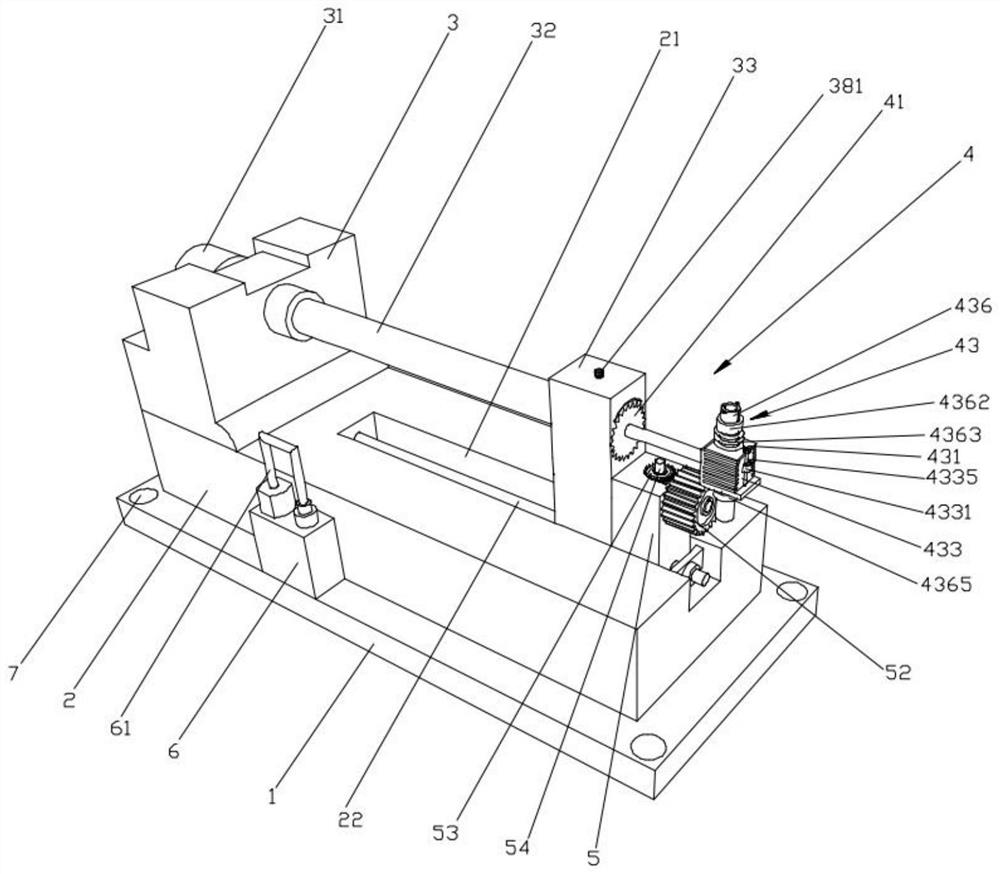

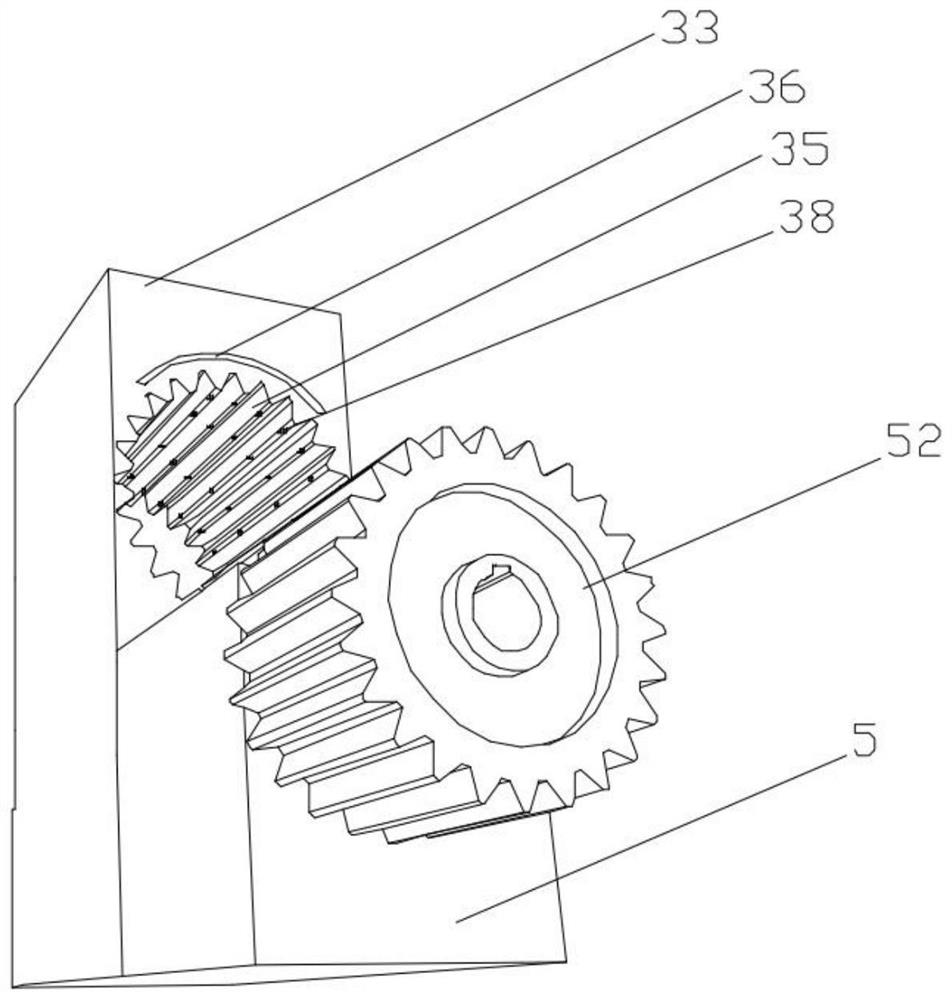

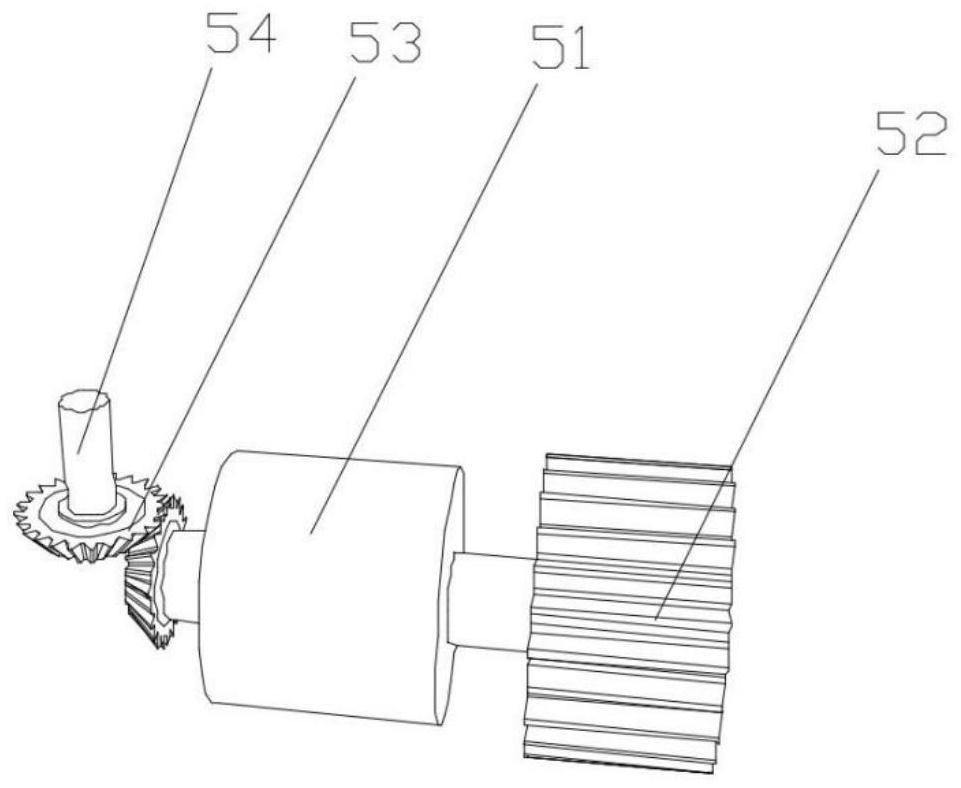

[0028] Such as Figure 1-10 As shown, it is a combination fixture for drill bit production and processing in this embodiment, including a fixture seat 1, a clamping table 2 is fixedly arranged on the fixture seat 1, and a cylinder seat 3 is provided at one end of the top surface of the clamping table 2. 3 is fixedly provided with a cylinder 31, the piston rod of the cylinder 31 is coaxially provided with a connecting shaft 32, and the first end of the connecting shaft 32 is fixedly arranged on the piston rod of the cylinder 31, and the second end of the connecting shaft 32 is fixedly provided with The angle adjustment seat 33, the second end of the connecting shaft 32 is provided with a positioning shaft hole 34, the other end of the top surface of the clamping table 2 is provided with an adjustment groove 21, and the bottom of the angle adjustment seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com