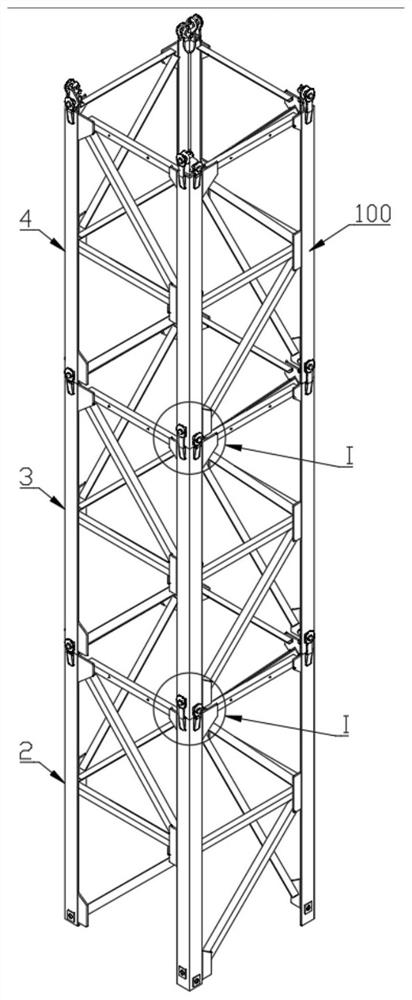

Tower crane tower body combination method and combined tower body device

A technology of tower cranes and combined methods, which is applied in the direction of cranes, mechanical equipment, and rod connections, etc., can solve problems such as the inability to achieve independent heights of the tower body, lifting, etc., to improve interchangeability and utilization, and to solve potential safety hazards , the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

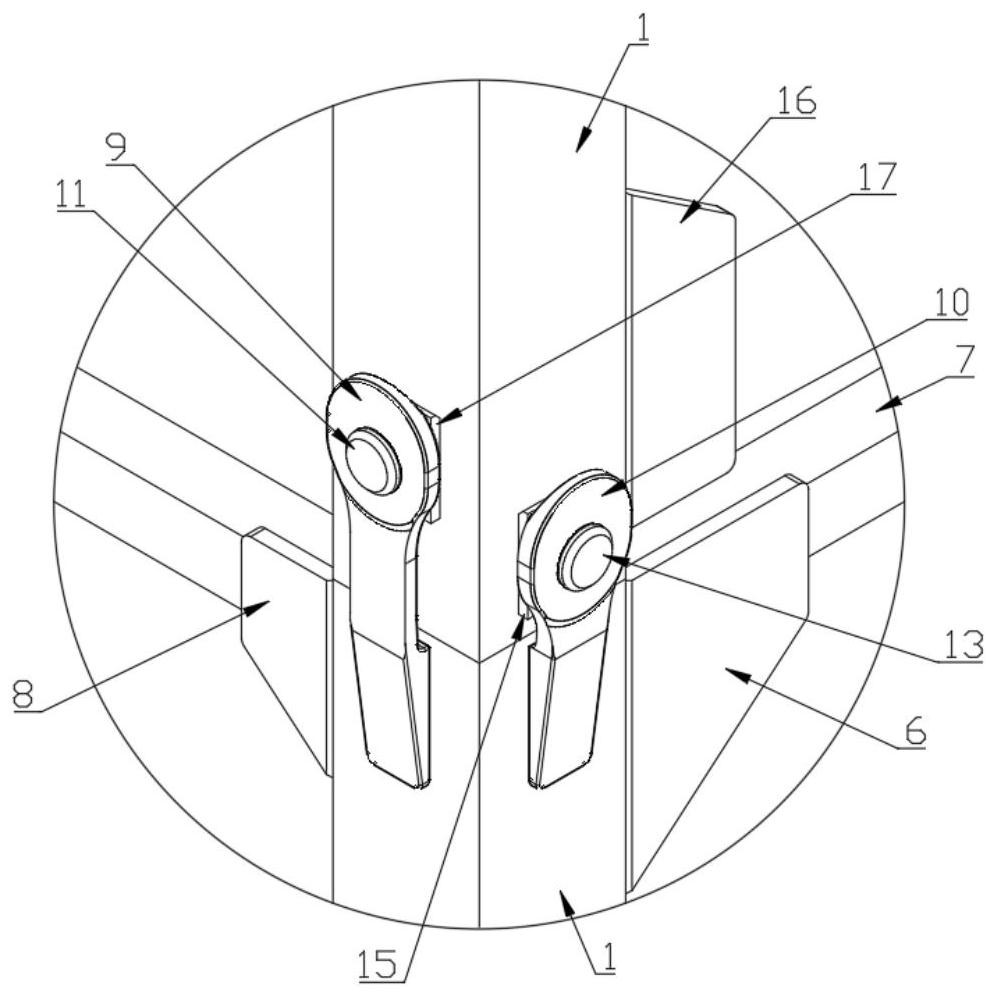

Embodiment 1

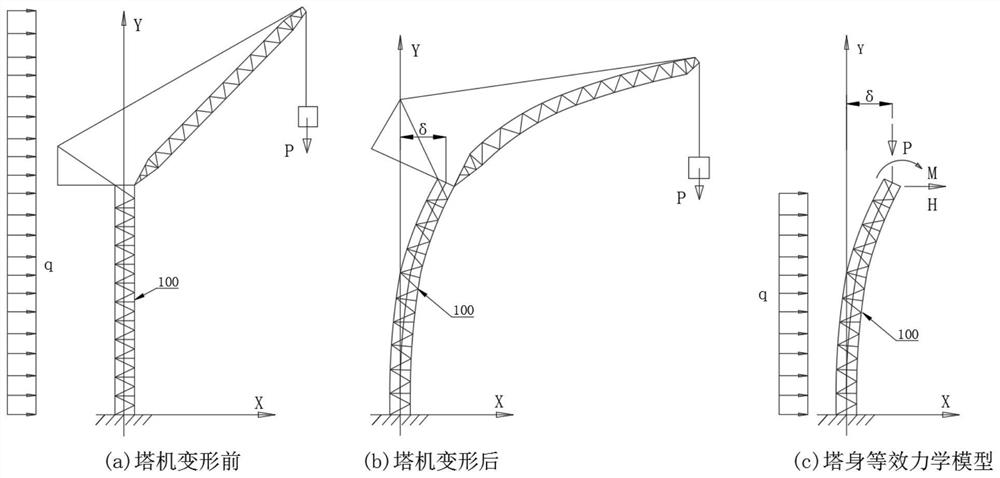

[0069] Such as Figure 6 , 7 As shown, for the same type of tower crane, the load on the upper part of the tower body is constant, while the load on the tower body will change with the height. Among them, M, P, H, and q are fixed values in the same type of tower crane, and the bending moment value M of different heights of the tower body 0 It is directly related to the height L of the tower body, the closer to the foundation, the M 0 is the bending moment value at the root of the tower, such as figure 2 As shown, the root of the tower crane body, that is, the foundation tower body, is stressed, and the bending moment M borne by the tower body is 0 The greater the value of the flexural modulus W or Wx of the cross-section of the tower body is determined by the material of the main limb, that is, the size of the angle steel of the main limb, and the stress value σ borne by any cross-section of the tower body must be less than the national standard The specified allowable ...

Embodiment 2

[0082] Also, the specification model is designed as a 125tm tower crane as an example for illustration;

[0083] When the section X-X is located 9 meters away from the foundation, the main leg adopts 160x160x16 angle steel, and the section flexural modulus Wx =14034cm 3 , the material is Q355B, the allowable stress [σ]=355 / 1.34=264.9MPa; that is

[0084] Mx=(M+H×(L-x)+q×(L-x) 2 / 2)=2220+30x(45-9)+0.84x(45-9) 2 / 2=3844.32kNm

[0085] σ= Mx / Wx=(3844.32x1000)(Nm) / 14034 (cm 3 )=273.93MPa>264.9;

[0086] From the above calculation results, it can be seen that when X=9 meters, that is, when the crane tower is closer to the section of the foundation, generally speaking, the closer to the ground, the greater the bending moment M borne by the tower body, A larger main leg angle steel structure is required to meet the bending moment and load requirements. The use of 160x160x16 angle steel for the main leg angle steel cannot meet its use requirements, and a larger specification of t...

Embodiment 3

[0088] Also, the specification model is designed as a 125tm tower crane as an example for illustration;

[0089] When the section X-X is located 9 meters away from the foundation, the main leg adopts 180x180x18 angle steel, and the section flexural modulus Wx =17458.25cm 3 , the material is Q355B, the allowable stress [σ]=355 / 1.34=264.9MPa; that is

[0090] Mx=(M+H*(L-x)+q*(L-x) 2 / 2)=2220+30x(45-9)+0.84x(45-9) 2 / 2=3844.32kNm

[0091] σ= Mx / Wx=(3844.32x1000)(Nm) / 17458.25 (cm 3 )=220.2MPa<264.9=[σ];

[0092] From the above calculation results, it can be seen that when X=9 meters, that is, when the crane tower is closer to the section of the foundation, generally speaking, the closer to the ground, the greater the bending moment M borne by the tower body, A larger main leg angle steel structure is required to meet the bending moment and load requirements. The main leg angle steel can use 180x180x18 angle steel to meet its use requirements, that is, use the main leg angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com