Heat exchange structure and method of ultralow-temperature electromagnetic valve

A technology of heat exchange structure and solenoid valve, applied in the direction of valve heating/cooling device, valve operation/release device, valve details, etc., can solve the problems of elongating the height of ultra-low temperature solenoid valve and restricting the application range, etc., and achieve improvement Effects of heat exchange efficiency, distance reduction, and increase in contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

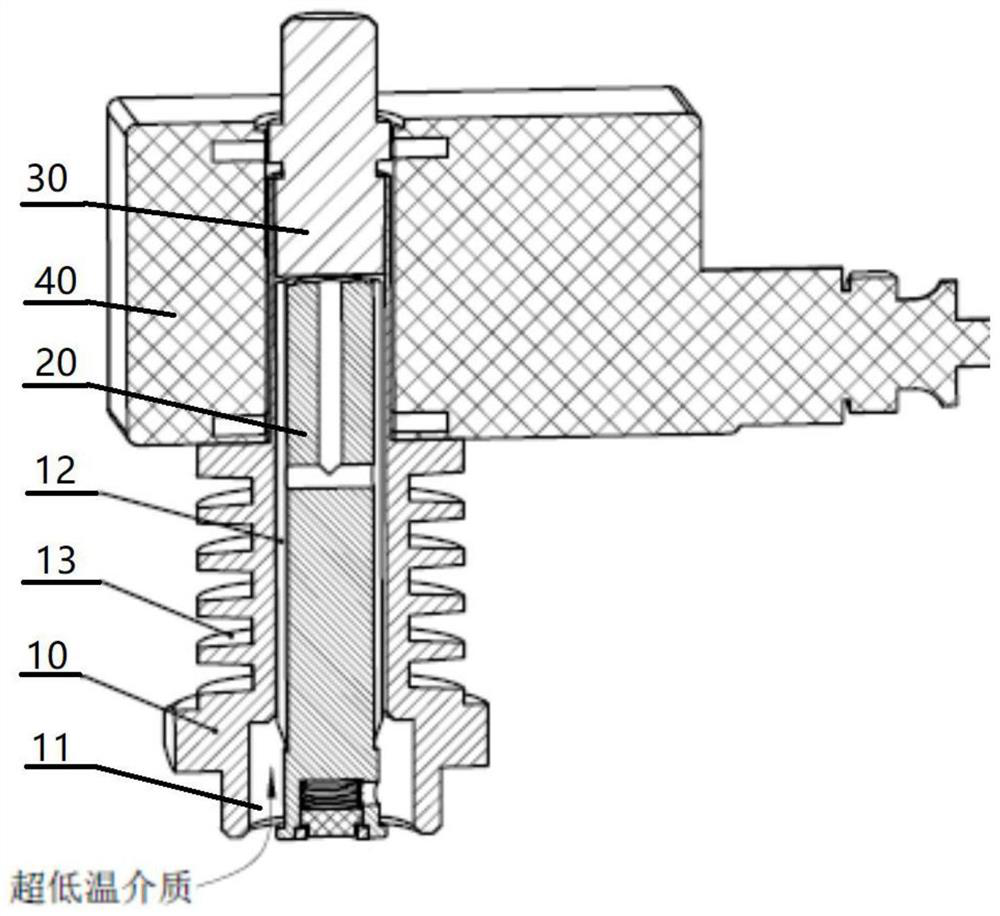

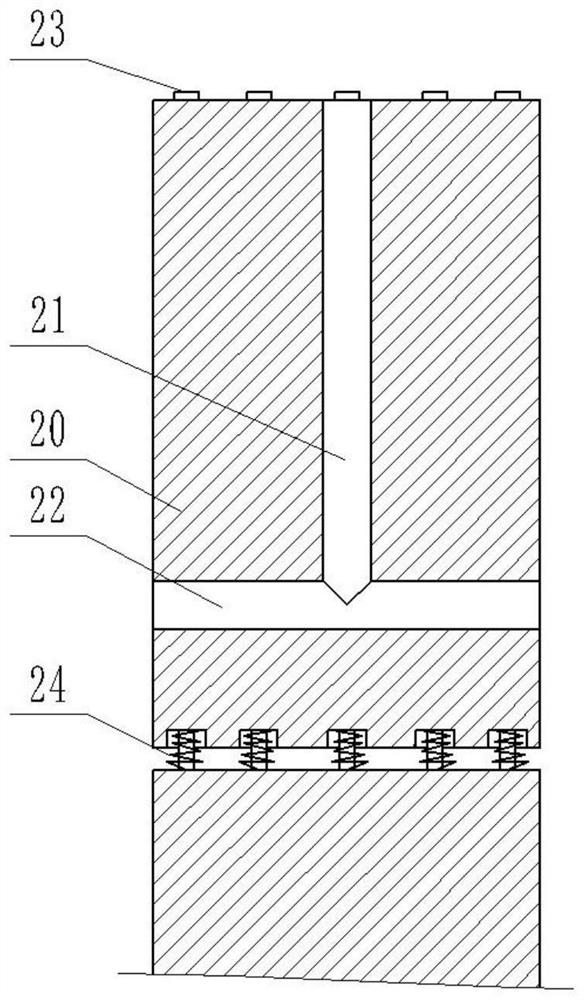

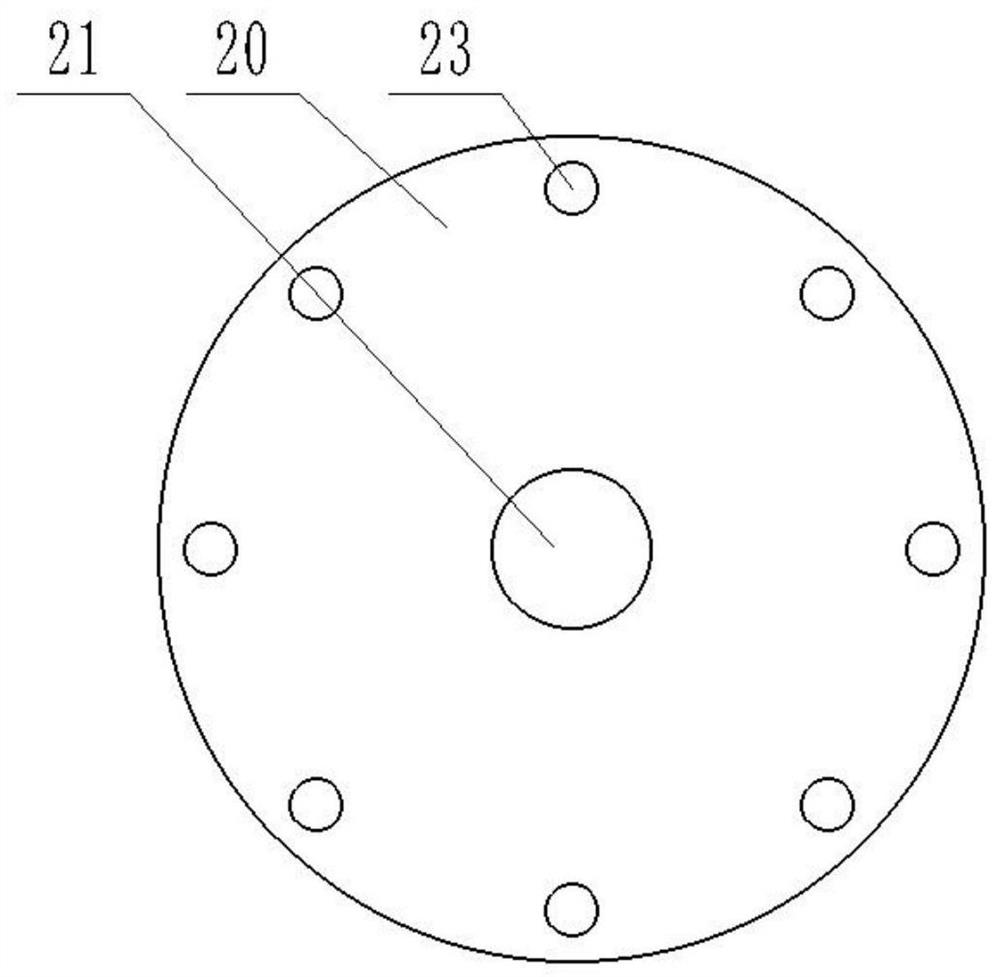

[0042] A heat exchange structure of an ultra-low temperature electromagnetic valve, wherein, such as figure 1 As shown, it includes: a valve seat 10 , a moving core 20 , a static core 30 , and a coil 40 .

[0043] Such as figure 1 As shown, the valve seat 10 has a movable cavity 11 and an annular structure 13 . The active chamber 11 is located in the valve seat 10 . The annular structures 13 are distributed on the outer surface of the valve seat 10, and the annular structures 13 are located on the side of the movable chamber 11. There are multiple annular structures 13, and there is a heat exchange space for air circulation between the multiple annular structures 13.

[0044] The moving core 20 is slidably arranged in the movable chamber 11 , and the moving core 20 and the side wall of the movable chamber 11 form a movement gap 12 , through which the heat exchange with the outside air is realized. The static core 30 is fixedly arranged on the movable cavity 11 , and the stati...

Embodiment 2

[0057] A heat exchange method for an ultra-low temperature electromagnetic valve, which includes the following steps:

[0058] When the ultra-low temperature medium gradually flows close to the coil 40 through the movement gap 12 around the moving core 20, during this process, when the medium contacts the side wall of the movable chamber 11, it continuously exchanges heat with the outside air to heat up the ultra-low temperature medium, so that the coil 40 The temperature of the medium at the place rises to the extent that the coil can bear;

[0059] At the same time, the valve seat 10 is processed with a multi-ring ring structure 13, so there is a heat exchange space between each ring structure 13, and when the outside air passes into the heat exchange space, it can communicate with each ring structure 13. Heat exchange greatly increases the contact area with the outside air, improves heat exchange efficiency, and achieves faster temperature rise. In this way, the distance re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com