Inner gear ring bounce detector

A detector and inner ring gear technology, applied in the field of inner ring gear runout detectors, can solve the problems of poor detection efficiency, unfavorable on-site application, increased detection and production costs, etc., to improve detection efficiency and save detection costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

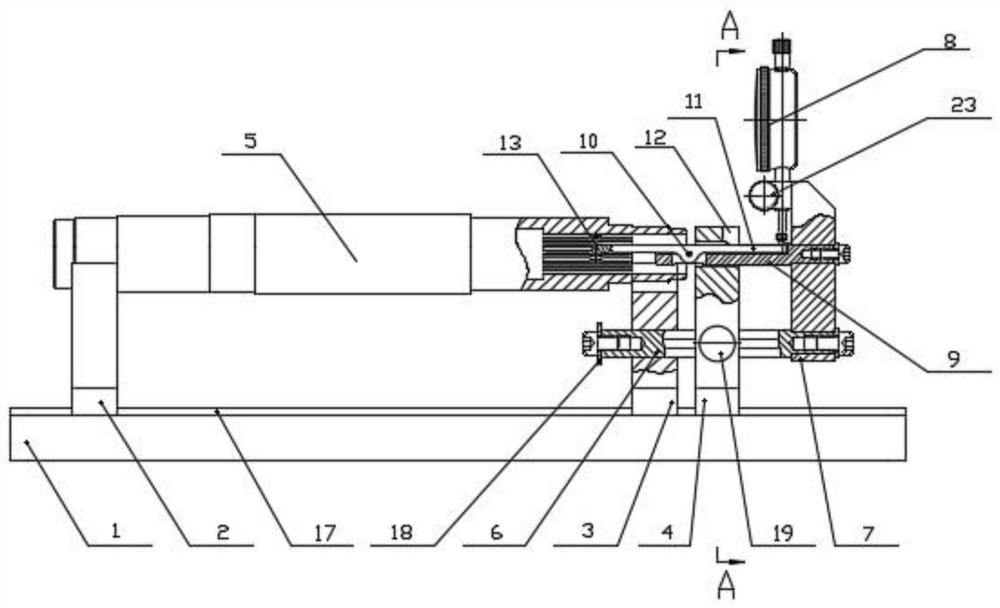

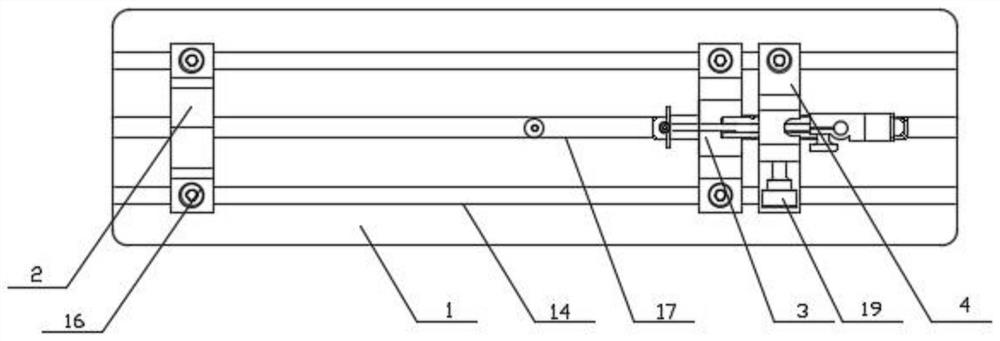

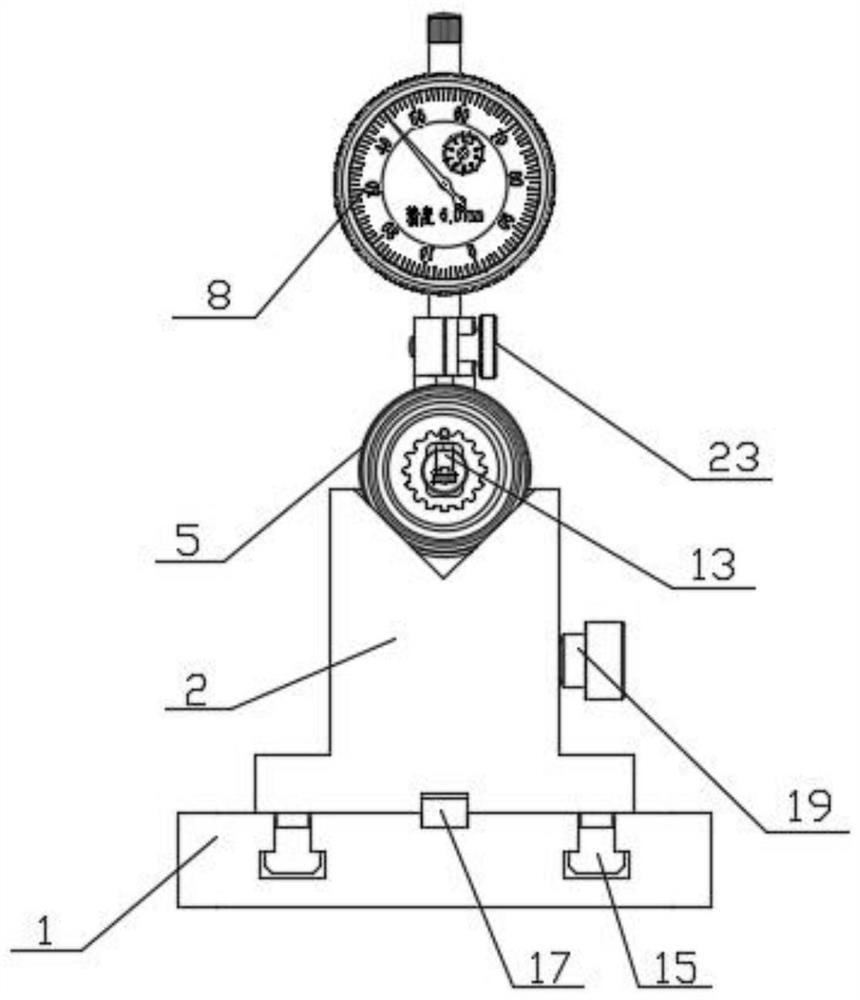

[0019] Such as Figure 1-Figure 5 As shown, a kind of internal ring gear runout detector includes a base plate 1, and a large V-shaped block 2, a small V-shaped block 3 and a fixed support 4 are sequentially installed on the base plate 1, and the large V-shaped block 1 and the The above-mentioned small mouth V-shaped block 2 is commonly used to place the workpiece 5 to be detected.

[0020] The middle part of the fixed support 4 is installed with a main guide column 6 in a plug-in manner, and one end of the main guide column 6 located outside the fixed support 4 is fixedly connected with the lower part of the gauge bracket 7 . A dial gauge 8 is installed on the top of the gauge bracket 7, and the dial gauge 8 is mounted on the gauge bracket 7 by a gauge screw 23 and its probe is set downward. The middle part of the gauge bracket 7 is fixedly connected to one end of a horizontally arranged thin guide post 9 , and the other end of the thin guide post is hingedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com